Forward film oxygen production process and device and application of forward film oxygen production process and device in oxygen-enriched firing system

A process and oxygen-enriched technology, which is applied in the forward membrane oxygen production process and device and its application in the oxygen-enriched firing system, can solve the problems of huge investment and huge investment energy, and achieve reduced investment and enhanced heat radiation , the effect of reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

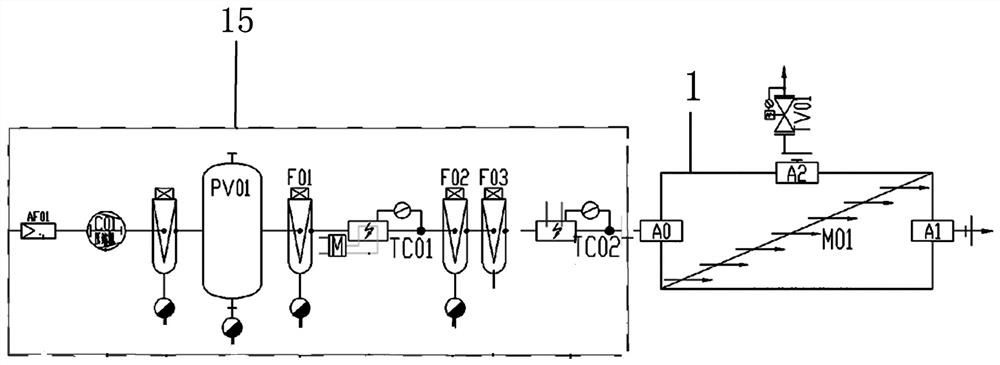

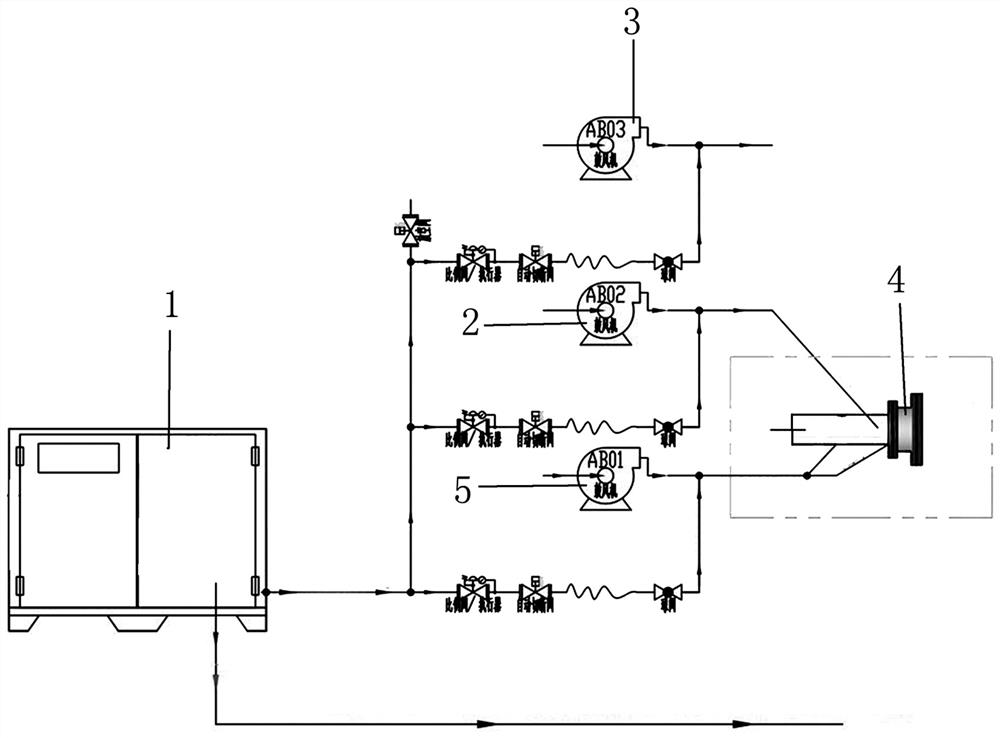

[0045] like figure 1 , 2 , 3, and 4, this case is the specific application of the oxygen-enriched technology prepared by the compressed air membrane method in a cement company. Through the oxygen-enriched combustion-supporting transformation of the company's current clinker output of 2800t / d rotary kiln, in order to achieve the technological purpose of increasing production and reducing consumption.

[0046] First of all, the main technical performance parameters of the membrane separator oxygen generator used in this case are as follows:

[0047] Compressed air demand: flow > 7700Nm³ / h, pressure > 0.7MPa, dew point < -15°C

[0048] A total of three sets of membrane separators are put into operation, each of which is skid-mounted as a whole and operated in parallel in groups;

[0049] Oxygen enrichment concentration: 37%~40%;

[0050] Oxygen-enriched flow: 2000~3200Nm 3 / h;

[0051] Nitrogen-enriched gas: 4600Nm 3 / h, purity 90%, pressure > 0.6MPa (gauge pressure), at...

Embodiment 2

[0069] A cement production line in a cement factory currently has a clinker output of 5,600 tons / day, and 34.5 tons / hour of coal with a calorific value of about 5,600 kcal / Kg; it currently has 3 compressed air stations with a total of 10 air compressors Compressor, can provide 1.0Mpa compressed air monthly 300m³ / min. It is required to increase the production by 5% after the oxygen-enriched technology is prepared by the compressed air membrane method, or reduce the fuel coal consumption by more than 5%, and the condition of the kiln will not be affected after switching to low-quality coal.

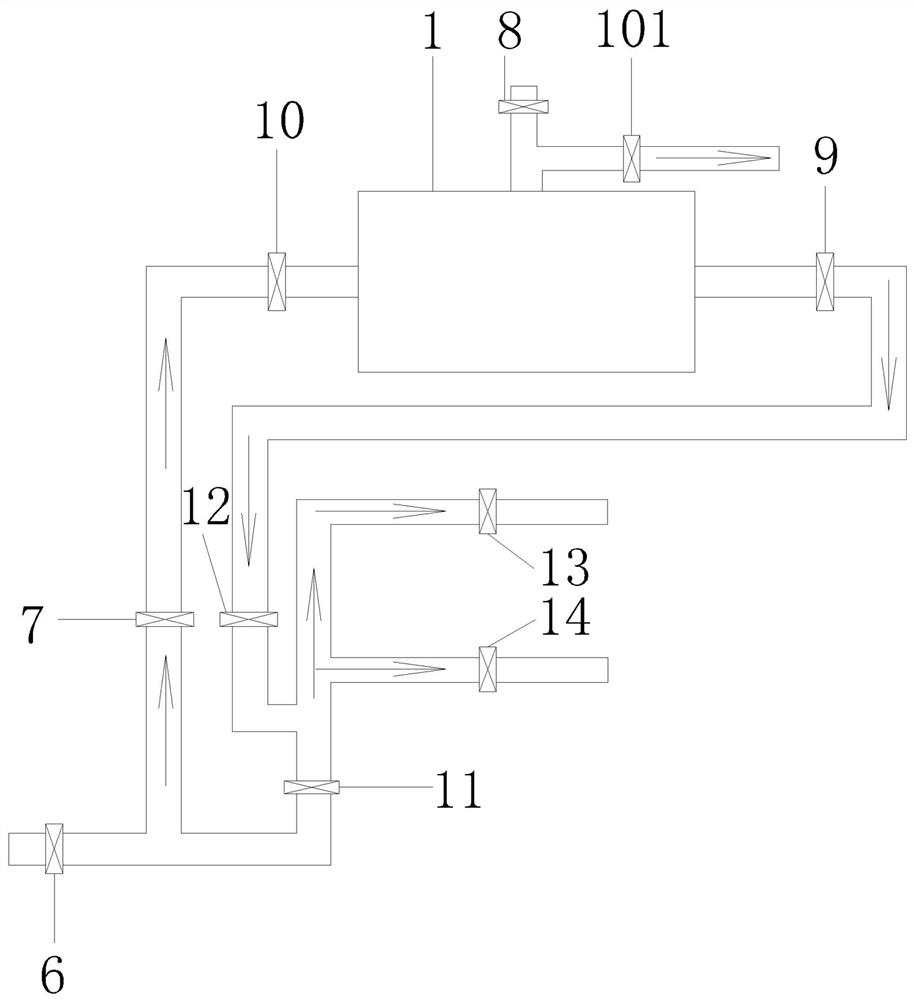

[0070] According to the demand, combined with the actual operation and overall situation of the kiln, it is planned to make full use of the original equipment of the cement plant for dust removal and blockage removal. The pressure is ~0.7MPa. After being "filtered" by the membrane separation system, two gases can be produced:

[0071] One is 30~40% oxygen-enriched air; it can be directly se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com