Soil electrostatic adsorption, screening and subpackaging all-in-one machine

An electrostatic adsorption, all-in-one technology, used in electrostatic effect separation, sieving, packaging, etc., can solve the problems of secondary pollution, reduce the soil preservation effect of jars, and unfavorable soil processing, and achieve the effect of easy placement and removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

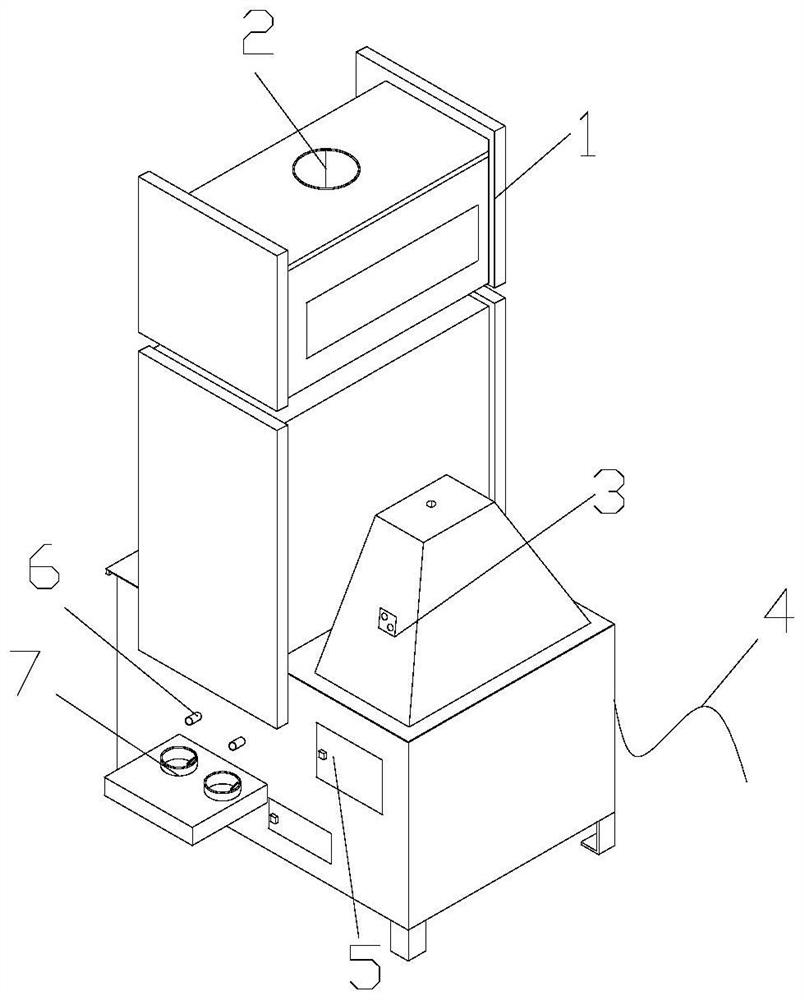

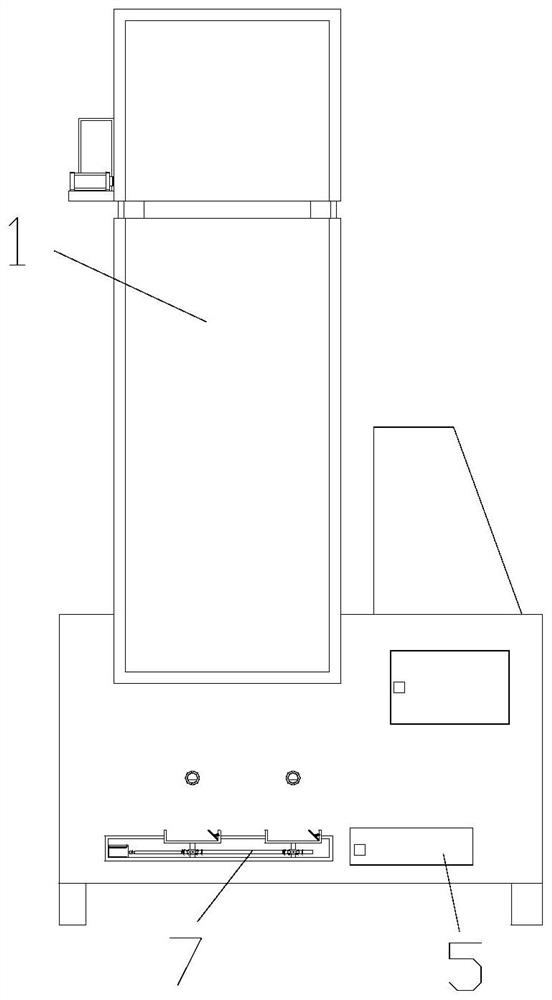

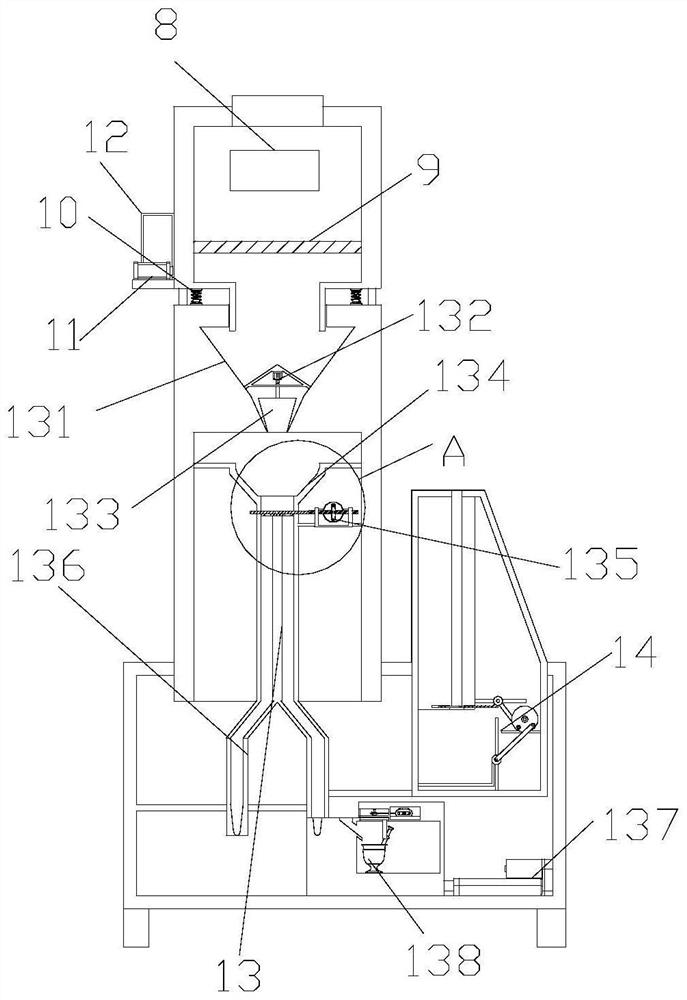

[0037] see figure 1 with figure 2 , the present invention provides a soil electrostatic adsorption, screening, sorting and packaging machine: including a main body 1, a material inlet 2, a controller 3, a power cord 4, a door leaf 5, a discharge pipe 6, a limit assembly 7, and an electrostatic generating electrode 8 , sieving net 9, spring 10, vibrator 11, electrostatic adsorption device 12, equalizing mechanism 13 and connecting assembly 14, the left end of the top of the main body 1 is connected with a material inlet 2, through which the material to be processed can be placed, The front end of the main body 1 is provided with a controller 3, the rear end of the main body 1 is provided with a power cord 4, the lower part of the front end of the main body 1 is hinged with the door leaf 5, which is convenient for taking out the objects in the interior, and the lower end of the main body 1 is fixedly connected with a discharge pipe 6, The upper end of the main body 1 is provid...

Embodiment 2

[0044] The present invention provides an integrated soil electrostatic adsorption, screening, sorting and packaging machine. The top of the plugging groove 141 runs through the right end of the top of the main body 1, which facilitates the placement of the bottle stopper. The bottom of the bottom frame 1381 is slidingly connected with the inner bottom of the main body 1 to improve The upper left end of the bottom frame 1381 is provided with a groove matching the lower end of the shunt pipe 136, and the groove is connected to the discharge pipe 6 at the right end of the main body 1, and the left and right ends of the matching plate 1356 run through the lower end side of the receiving chamber 134 , to be convenient to the equally divided transmission of the soil at the lower end of the receiving cavity 134 to the left and right ends of the shunt pipe 136, a blocking plate is provided on the right side of the upper end of the main body 1, the blocking plate can be removed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com