Treatment and comprehensive utilization method of foundation engineering slurry

A basic engineering and slurry technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the high cost of reuse of mud cake and waste liquid, the ineffective use of mud cake, and treatment procedures Complicated problems, to solve the problem of discharge or Sinotrans treatment, to promote the utilization of resources, and to achieve the effect of simple processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

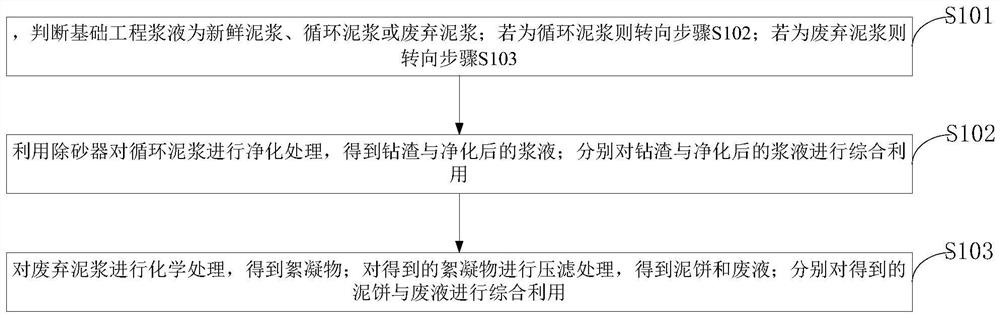

[0064] A method for treating and comprehensively utilizing grout in foundation engineering.

[0065] Foundation engineering slurry includes fresh slurry, recycled slurry and waste slurry.

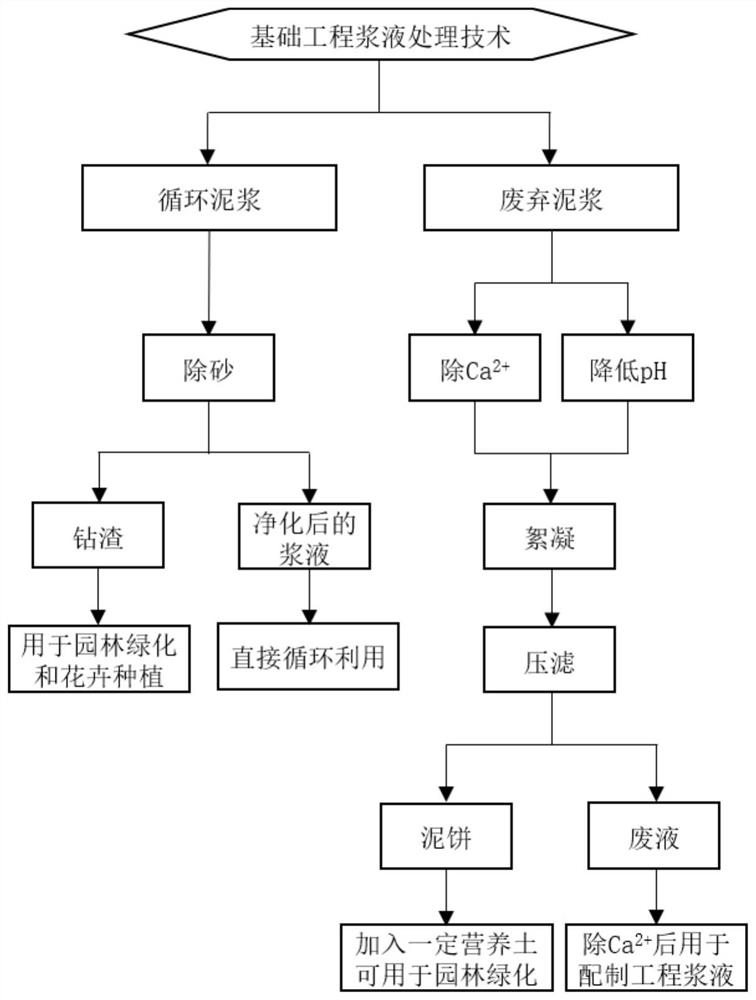

[0066] The treatment and comprehensive utilization methods of circulating mud include sand removal and purification treatment, comprehensive utilization of drilling slag and comprehensive utilization of purified mud.

[0067] The treatment and comprehensive utilization methods of waste mud include chemical treatment, pressure filtration treatment, comprehensive utilization of mud cake and comprehensive utilization of waste liquid.

[0068] Sand removal treatment refers to the purification treatment of circulating mud with cyclone desander or similar equipment to obtain drilling slag and purified mud respectively.

[0069] Cyclone desander or similar equipment should use a filter screen with a mesh number of 80 mesh or finer to control the solid phase content in the purified mud.

[0070] ...

Embodiment 2

[0085] A treatment and comprehensive utilization technology of circulating mud in the process of foundation engineering construction ( figure 1 ), which mainly consists of sand removal treatment, comprehensive utilization of drilling slag and comprehensive utilization of purified mud.

[0086] The performance of circulating mud and fresh mud was tested and compared, and the results are shown in Table 1.

[0087] Table 1 Basic properties of fresh mud and circulating mud

[0088]

[0089] The results show that during the mud circulation process, a large amount of cuttings and cement were mixed in, resulting in a high density of the circulating mud, Ca 2+ The concentration increases obviously, the viscosity decreases, and the montmorillonite content decreases.

[0090] 1. Sand removal treatment

[0091] Use a cyclone desander or similar equipment to purify the circulating mud to obtain drilling slag and purified mud respectively. The screen of the cyclone desander or simila...

Embodiment 3

[0114] Embodiments of the present invention provide a treatment and comprehensive utilization technology of waste mud in basic engineering ( figure 1 ), mainly composed of chemical treatment, filter press treatment, comprehensive utilization of mud cake and comprehensive utilization of waste liquid.

[0115] The basic properties of the waste mud were tested, and the results are shown in Table 3.

[0116] Table 3 Basic properties of waste mud

[0117]

[0118] The results showed that compared with fresh mud properties, Ca in waste mud 2+ If the concentration and pH are too high, the content and viscosity of montmorillonite will be greatly reduced.

[0119] 1. Chemical treatment

[0120] (1) Decalcification

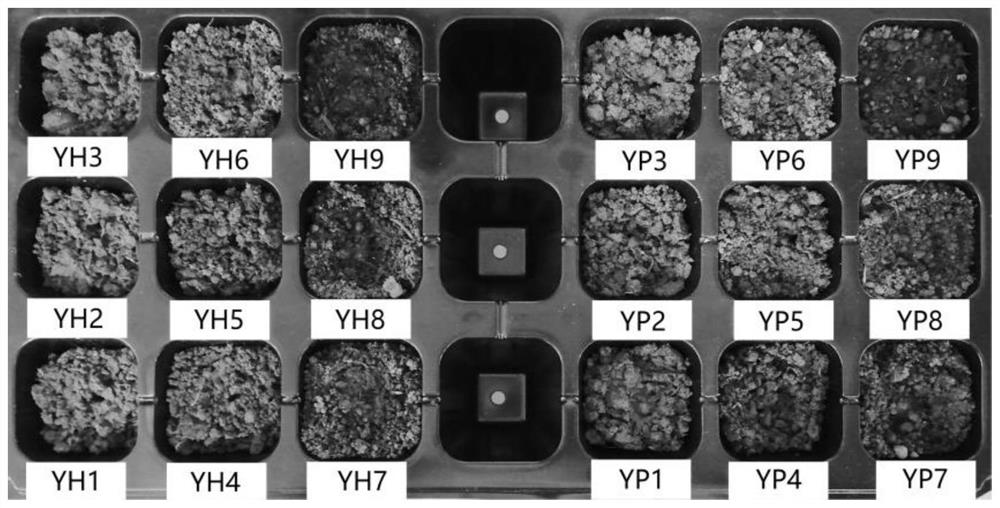

[0121] To compare the decalcification effect of different decalcifiers on waste mud, the specific experimental steps are as follows:

[0122] (a) Prepare 100g of 1% Na 2 CO 3 solution, SAPP solution and NaHCO 3 solution;

[0123] (b) Measure 100g of waste mud fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com