Glass, metal fabric for forming and film removing of glass, forming mold and film removing method

A glass forming and metal fabric technology, which is applied to the film removal method and the fields of glass, forming molds and metal fabrics, can solve the problems of increased glass production costs, large equipment and processing costs, and reduced glass processing efficiency, and achieves convenient film removal, The effect of improving production efficiency and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

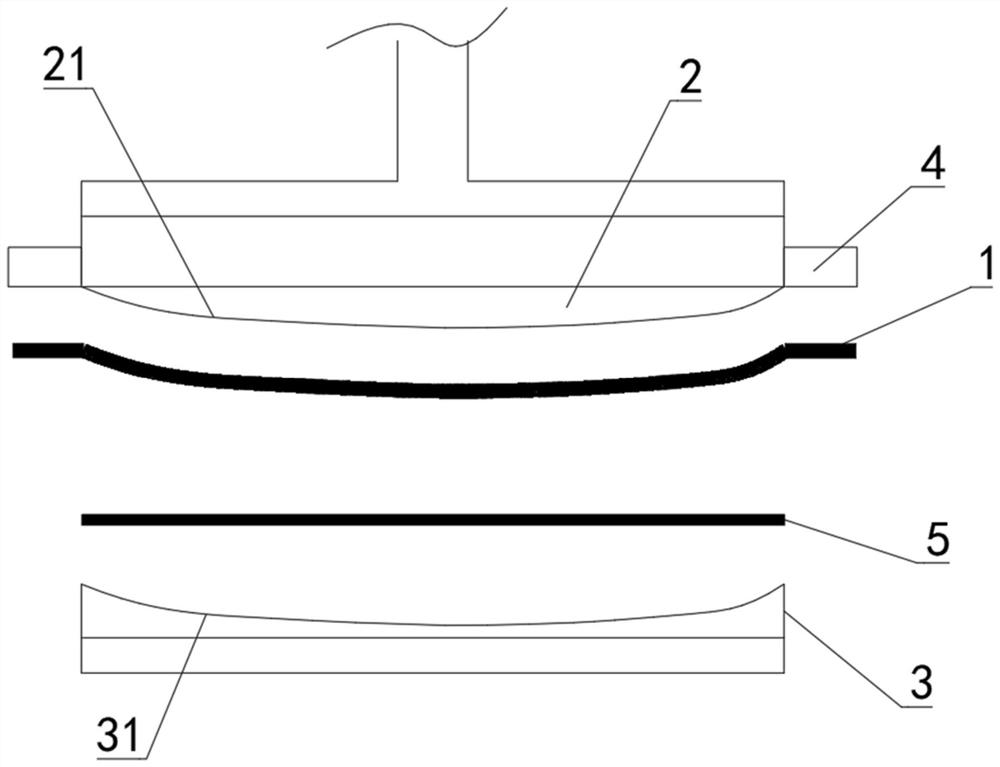

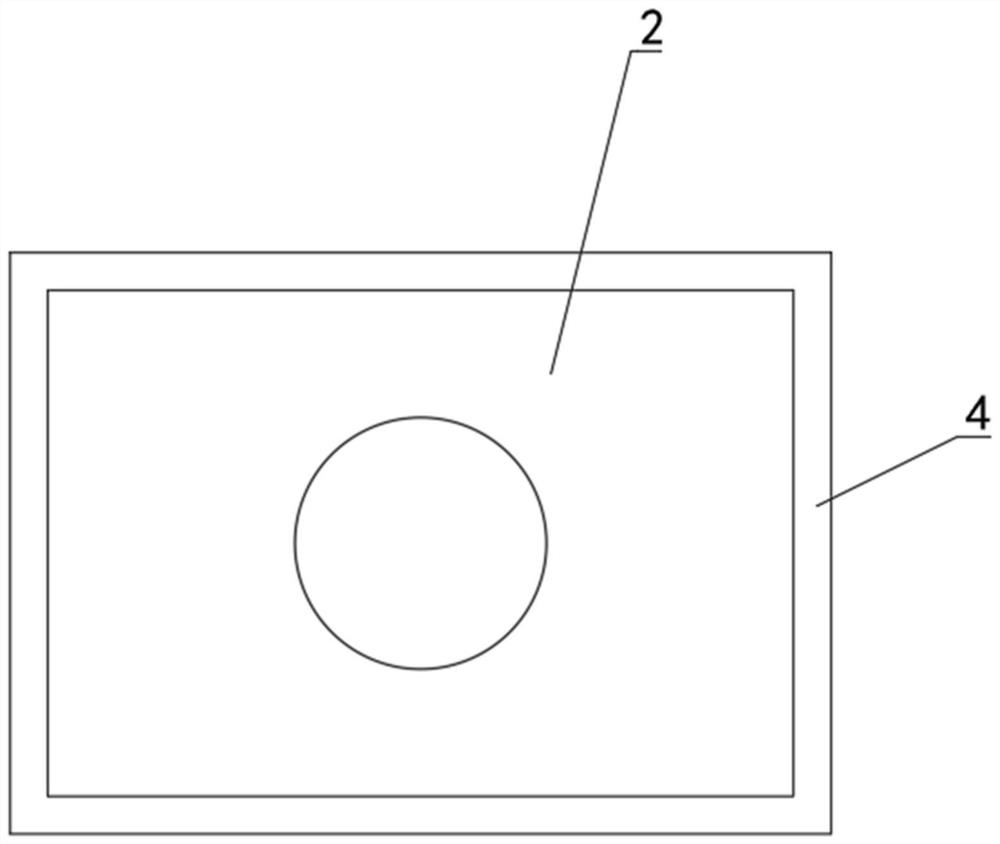

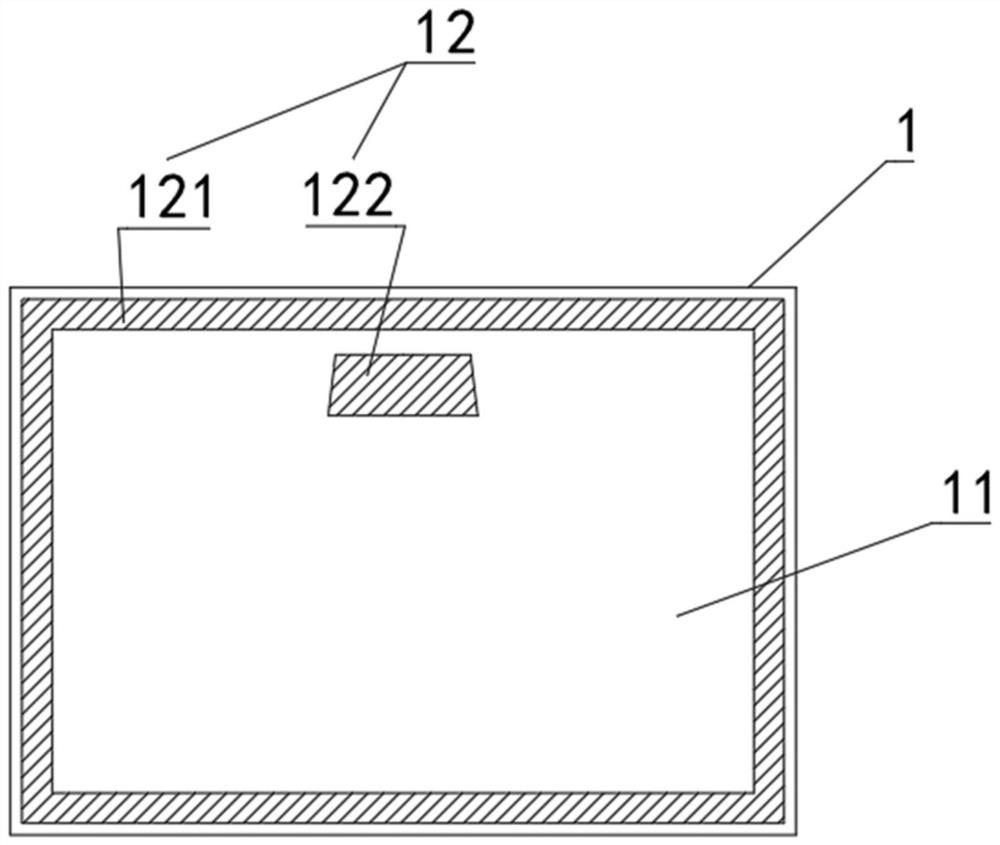

[0041] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0042] Please refer to image 3 As shown, a metal fabric 1 for glass forming film removal of the present invention includes a contact protection area 11 and a contact film removal area 12;

[0043] The contact protection zone 11 is in direct contact with the functional coating of the corresponding area on the surface of the glass 5 without destroying the functional coating;

[0044] The contact removal area 12 is in direct contact with the functional coating in the corresponding area on the surface of the glass 5 and can remove at least part of the functional coating.

[0045] Wherein, metal fabric 1 has certain flexibility, can make it close to the surface of forming mold and the surface of glass 5 in the process of forming glass 5, so that glass 5 can not dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com