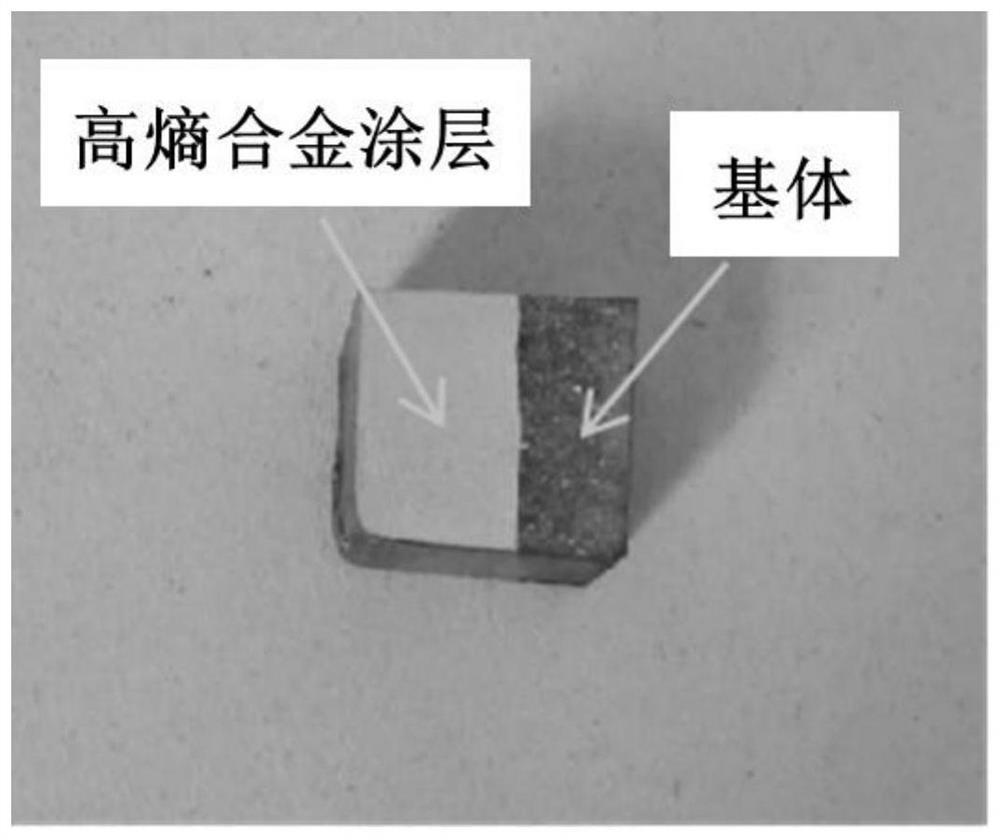

Composite material with high-entropy alloy coating on surface and preparation method of composite material

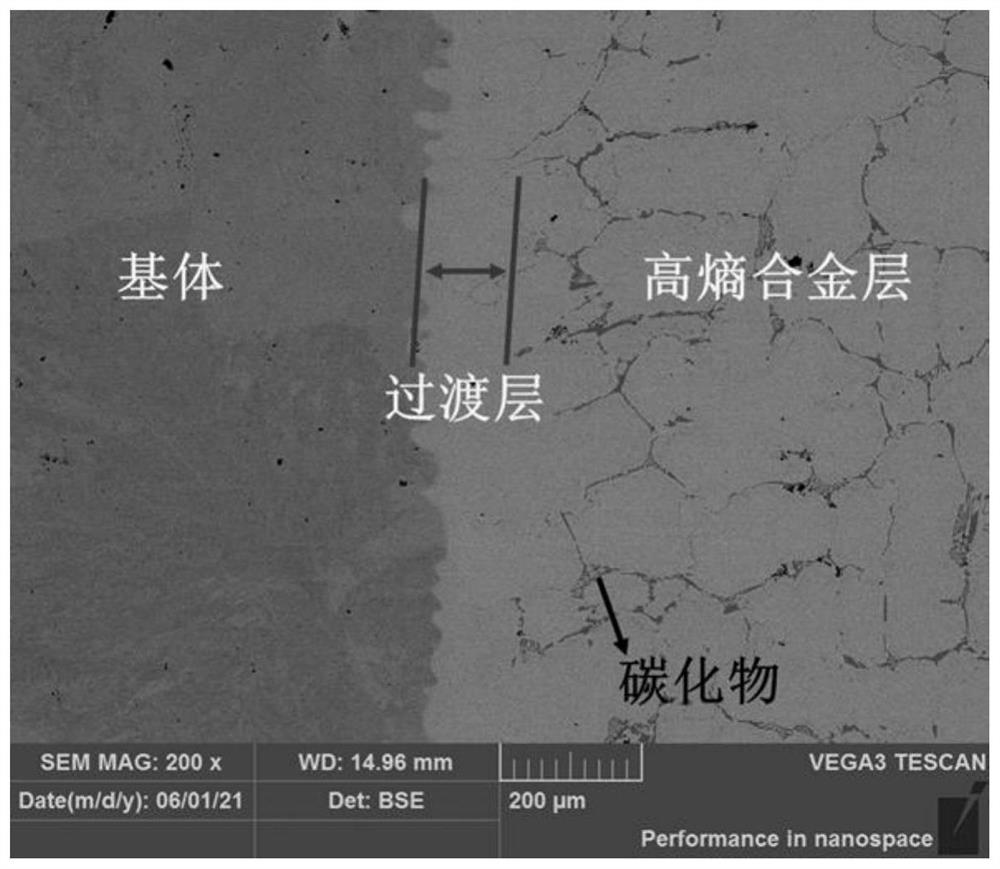

A technology of composite materials and high-entropy alloys, applied in coatings, metal processing equipment, manufacturing tools, etc., can solve problems such as high-entropy alloy coatings and substrates that are prone to cracks, and achieve crack-resistant and good metallurgical bonding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

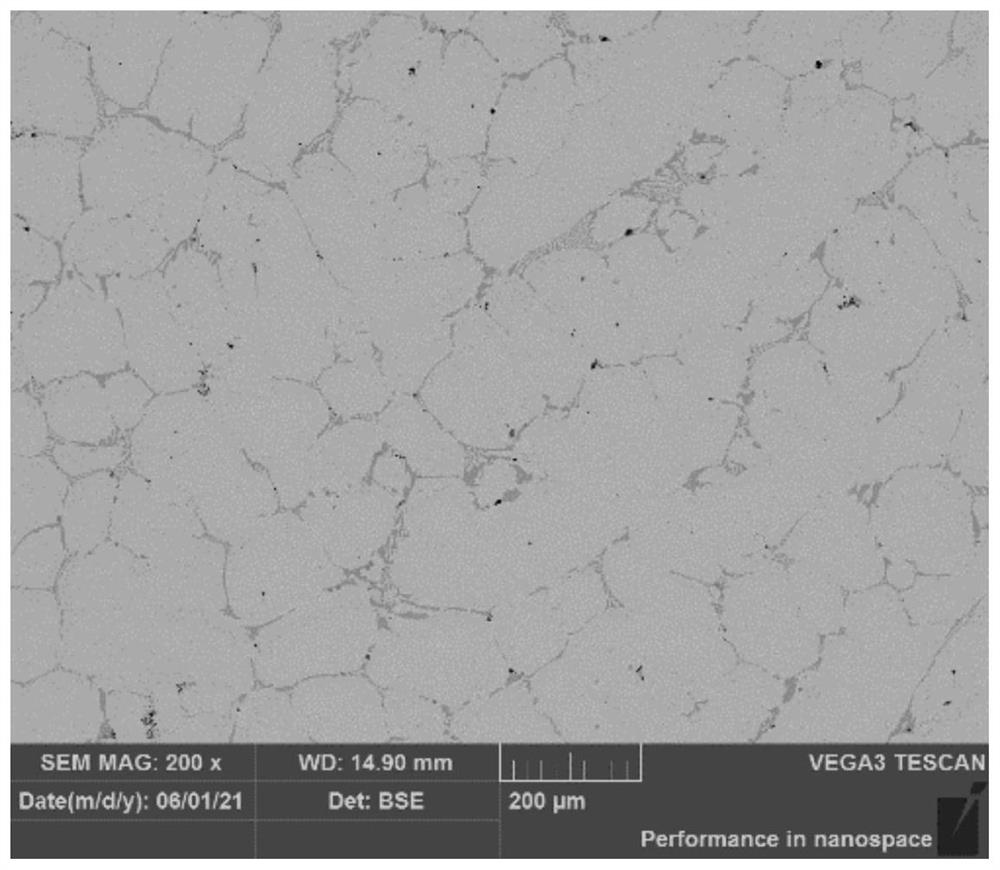

[0036] The preparation method of the composite material that the surface of the present embodiment contains high-entropy alloy coating comprises the following steps:

[0037](1) Cobalt powder, chromium powder, nickel powder, and manganese powder with an average particle size of 40 mesh are uniformly mixed with a ball mill to obtain a metal powder with an average particle size of 40 mesh. Wherein, the mass ratio of cobalt powder, chromium powder, nickel powder and manganese powder is 20:30:26:24.

[0038] (2) Mix the metal powder, binder and solvent evenly to obtain a coating solution. The mass ratio of the metal powder, the organic binder and the solvent is 20:1:1.5; the binder is an organic binder, the organic binder is polyvinyl butyral, and the solvent is ethanol.

[0039] (3) Coating the coating liquid on the surface of the lost foam model, the thickness of the coating liquid is 7 mm, and the coated model is obtained after the coating liquid is dried. Then embed the coat...

Embodiment 2

[0041] The preparation method of the composite material that the surface of the present embodiment contains high-entropy alloy coating comprises the following steps:

[0042] (1) Cobalt powder, chromium powder, nickel powder, and manganese powder with an average particle size of 60 mesh are uniformly mixed with a ball mill to obtain a metal powder with an average particle size of 60 mesh. Wherein, the mass ratio of cobalt powder, chromium powder, manganese powder and nickel powder is 25:25:25:25.

[0043] (2) Mix the metal powder, binder and solvent evenly to obtain a coating solution. The mass ratio of the metal powder, the organic binder and the solvent is 22:1:1.9; the binder is an organic binder, the organic binder is polyvinyl butyral, and the solvent is ethanol.

[0044] (3) Coating the coating liquid on the surface of the lost foam model, the thickness of the coating liquid is 6mm, and the coated model is obtained after the coating liquid is dried. Then embed the coat...

Embodiment 3

[0046] The preparation method of the composite material that the surface of the present embodiment contains high-entropy alloy coating comprises the following steps:

[0047] (1) Cobalt powder, chromium powder, nickel powder, and manganese powder with an average particle size of 80 mesh are uniformly mixed with a ball mill to obtain a metal powder with an average particle size of 80 mesh. Wherein, the mass ratio of cobalt powder, chromium powder, manganese powder and nickel powder is 23:27:26:24.

[0048] (2) Mix the metal powder, binder and solvent evenly to obtain a coating solution. The mass ratio of the metal powder, the organic binder and the solvent is 23:1:2.1; the binder is an organic binder, the organic binder is polyvinyl butyral, and the solvent is ethanol.

[0049] (3) Coating the coating liquid on the surface of the lost foam model, the thickness of the coating liquid is 5 mm, and the coated model is obtained after the coating liquid is dried. Then embed the coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com