Small and medium-sized bioethanol reforming hydrogen production device system and reforming hydrogen production method

A bio-ethanol, reforming hydrogen production technology, applied in the field of hydrogen production, can solve problems such as the impact of hydrogen production performance, and achieve the effects of improving energy efficiency, avoiding potential safety hazards, and long-term price competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

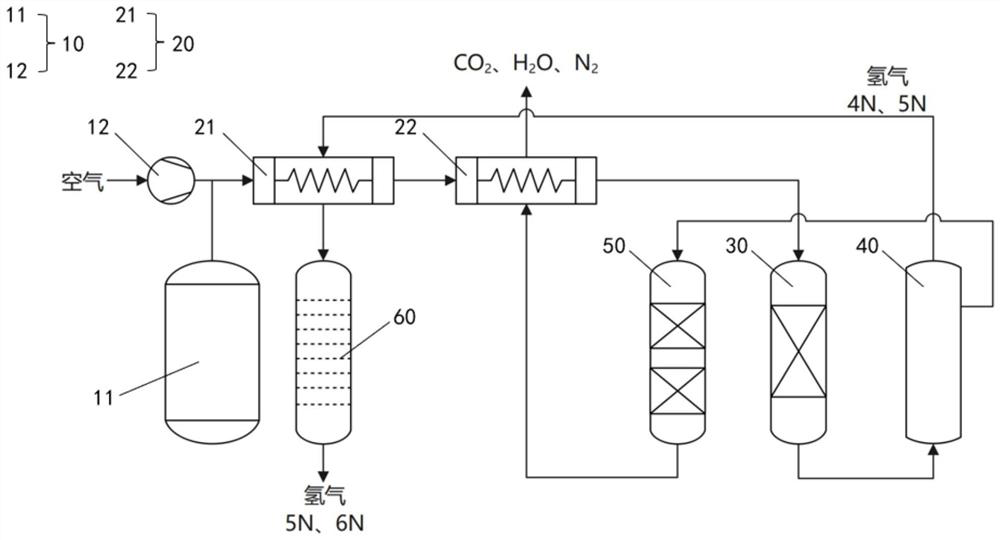

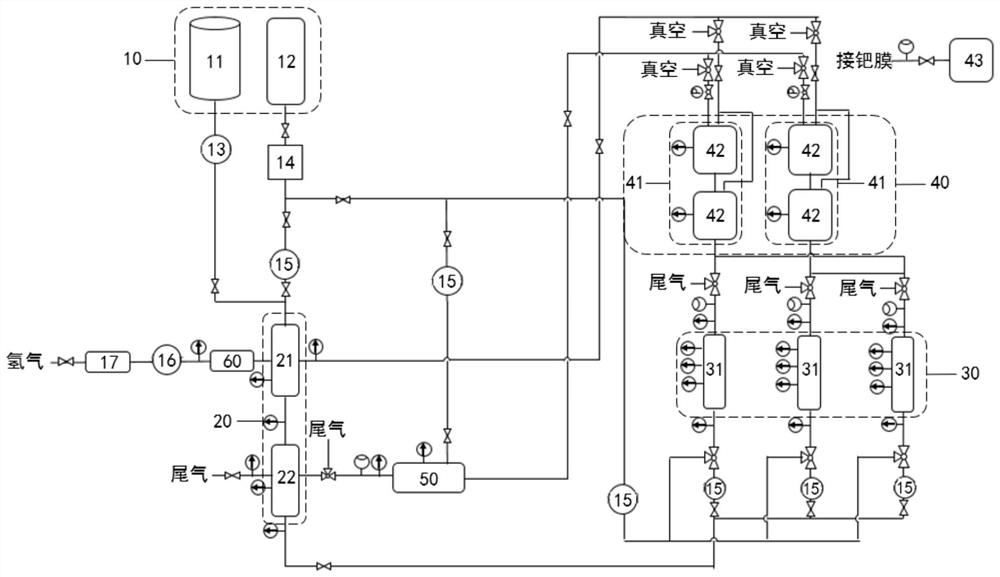

[0083] This embodiment provides a device system for small and medium-sized bioethanol reforming hydrogen production, such as figure 2 As shown, the device system includes a raw material supply unit 10, a heat exchange unit 20, an ethanol catalytic reforming unit 30, a hydrogen separation unit 40, a tail gas catalytic oxidation unit 50, a hydrogen purification unit 60 and a monitoring control unit ( figure 2 not shown). The raw material in the raw material supply unit 10 flows through the heat exchange unit 20, the ethanol catalytic reforming unit 30 and the hydrogen separation unit 40 in sequence; the hydrogen in the hydrogen separation unit 40 flows through the heat exchange unit 20 and the hydrogen purification unit 60 in sequence ; The tail gas in the hydrogen separation unit 40 flows through the tail gas catalytic oxidation unit 50 and the heat exchange unit 20 in sequence; the monitoring and control unit is used for real-time monitoring and controlling the stable operat...

Embodiment 2

[0091] This embodiment provides a device system for small and medium bioethanol reforming hydrogen production. In addition to changing the ethanol catalytic reforming unit 30 to include two sets of ethanol catalytic reforming subunits 31 connected in parallel, one set It is the ethanol catalytic reforming subunit to be used; at the same time, the hydrogen separation unit 40 is changed to include a set of hydrogen separation subunits 41, and the hydrogen separation subunit 41 is a palladium membrane hydrogen separation device 42. The rest of the structures and conditions are the same as those in Embodiment 1, so they will not be repeated here.

Embodiment 3

[0093] This embodiment provides a device system for small and medium-sized bioethanol reforming hydrogen production. In addition to changing the ethanol catalytic reforming unit 30 to include 4 groups of ethanol catalytic reforming subunits 31 connected in parallel, one of them It is the ethanol catalytic reforming subunit to be used; at the same time, the hydrogen separation unit 40 is changed to include three groups of hydrogen separation subunits 41 connected in parallel, and the hydrogen separation subunits 41 are three palladium membrane hydrogen separation devices 42 connected in series. The rest of the structures and conditions are the same as those in Embodiment 1, so they will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com