Method for improving cavitation resistance of material by using laser shock peening technology

A technology of laser shock strengthening and anti-cavitation, which is applied in the field of laser shock strengthening technology and cavitation, can solve the problems of different time and space characteristics, long test period, and difficult comparison of results, and achieve strong controllability and adaptability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0025] Aiming at the deficiencies of the prior art, the present invention adopts a new cavitation resistance method, which is a laser shock strengthening technology, which can effectively improve the cavitation resistance.

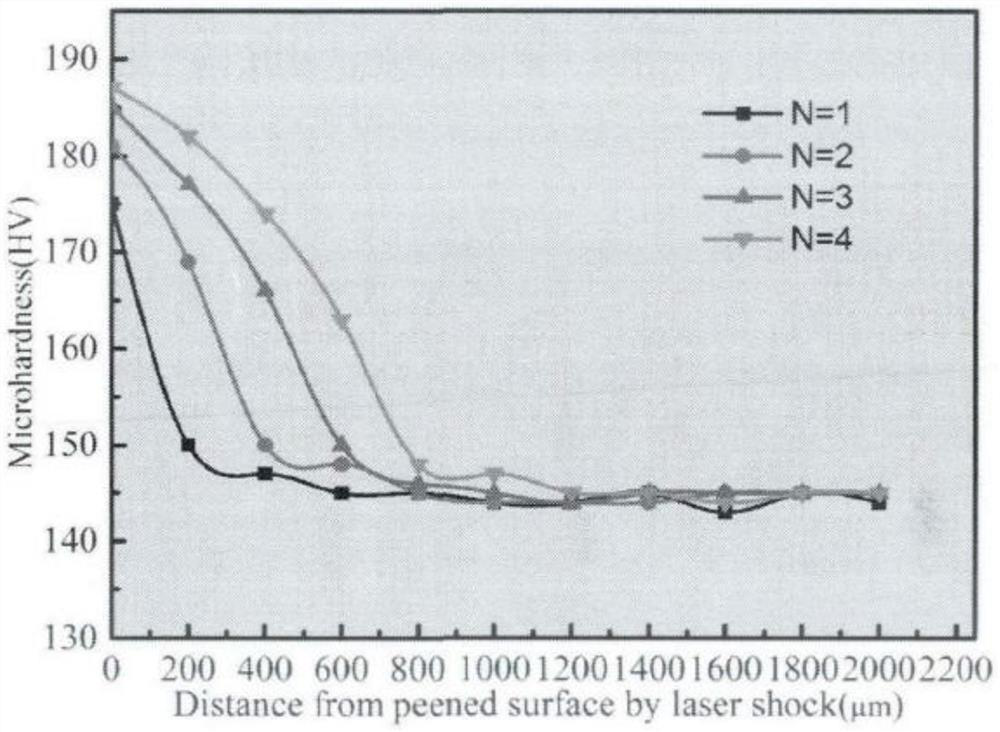

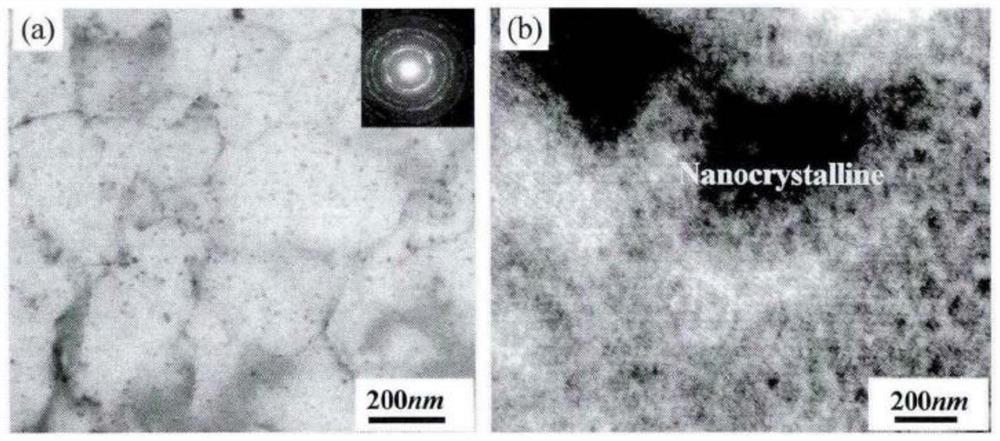

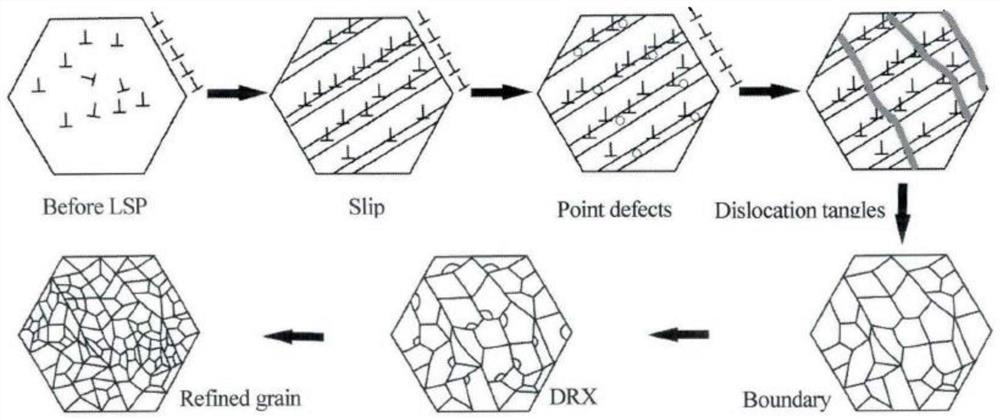

[0026] A method of improving the cavitation resistance of materials by using laser shock strengthening technology. The metal surface is irradiated with short pulse and high peak power density laser, so that the absorbing protective layer coated on the metal surface absorbs laser energy and undergoes explosive gasification and evaporation. Generate high-temperature, high-pressure plasma; the plasma is constrained by the confinement layer, forming a high-pressure shock wave and propagating to the inside of the material, using the force effect of the shock wave to produce plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com