Maleic anhydride-styrene copolymer microsphere as well as preparation method and application thereof

A technology of styrene copolymer and maleic anhydride, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as complex preparation process and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The first aspect of the present invention provides a kind of preparation method of maleic anhydride-styrene copolymer microsphere, described method comprises the following steps:

[0026] (1) In an inert atmosphere, the polymerization monomer and the initiator are dissolved in the reaction medium to form a homogeneous solution;

[0027] (2) After the homogeneous solution is polymerized to obtain a copolymer emulsion suspension, centrifugal separation obtains the maleic anhydride-styrene copolymer microspheres;

[0028] Wherein, the polymerized monomers are maleic anhydride and styrene; based on the total weight of the polymerized monomers, the amount of maleic anhydride is 50-90wt%, and the amount of styrene is 10-50wt%;

[0029] Described reaction medium is the mixture of the compound shown in formula (1) and alkane;

[0030]

[0031] Among them, R 1 and R 2 Each independently represents an alkyl group having 1 to 6 carbon atoms.

[0032] In the present inventio...

Embodiment 1

[0069] Add 4.9g of maleic anhydride, 0.89g of azobisisobutyronitrile, 5.2g of styrene, 40ml of acetone and 60ml of hexane into a 500mL three-necked flask. React in a water bath for 5 hours. After the reaction is completed, the obtained polymer emulsion suspension is centrifuged at a speed of 2000 rad / min for 20 minutes to obtain 9.2 g of polymer microspheres A1, corresponding to a polymer yield of 91%. The size of polymer microsphere A1 is 1100 nm.

[0070] The polymer microsphere A1 was carried out 1 According to H NMR measurement, based on the total molar weight of each structural unit in the polymer, the molar content of structural unit A derived from maleic anhydride is 49%, and the molar content of structural unit B derived from styrene is 51%.

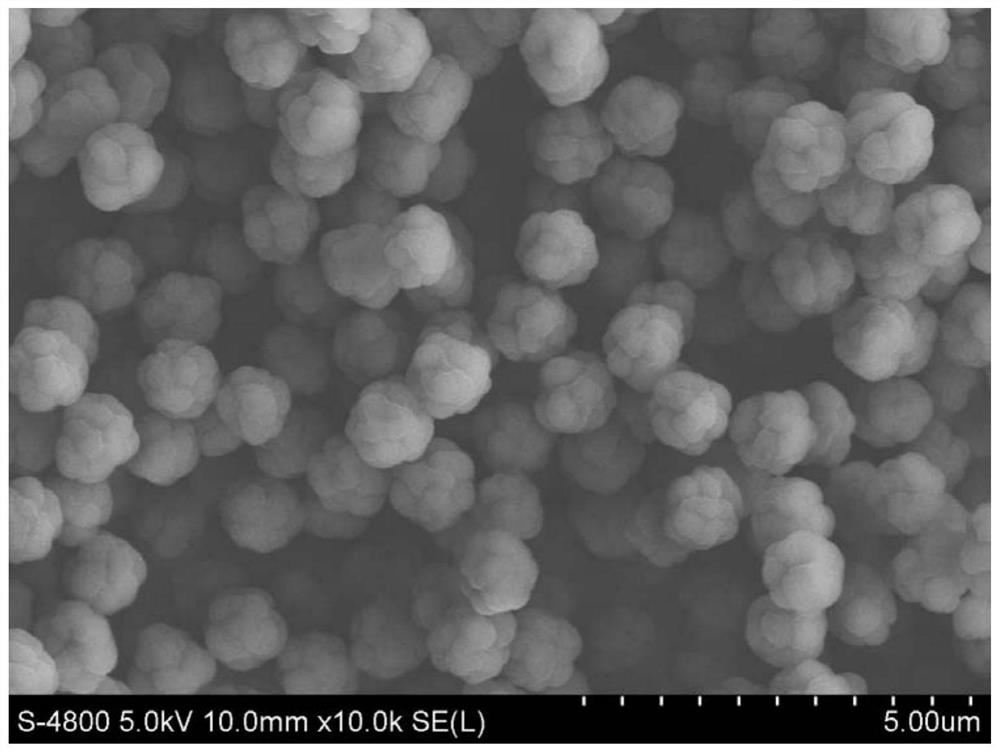

[0071] figure 1 is the SEM image of polymer microsphere A1, from figure 1 It can be seen that the maleic anhydride-styrene copolymer particles prepared in Example 1 are spherical polymer particles.

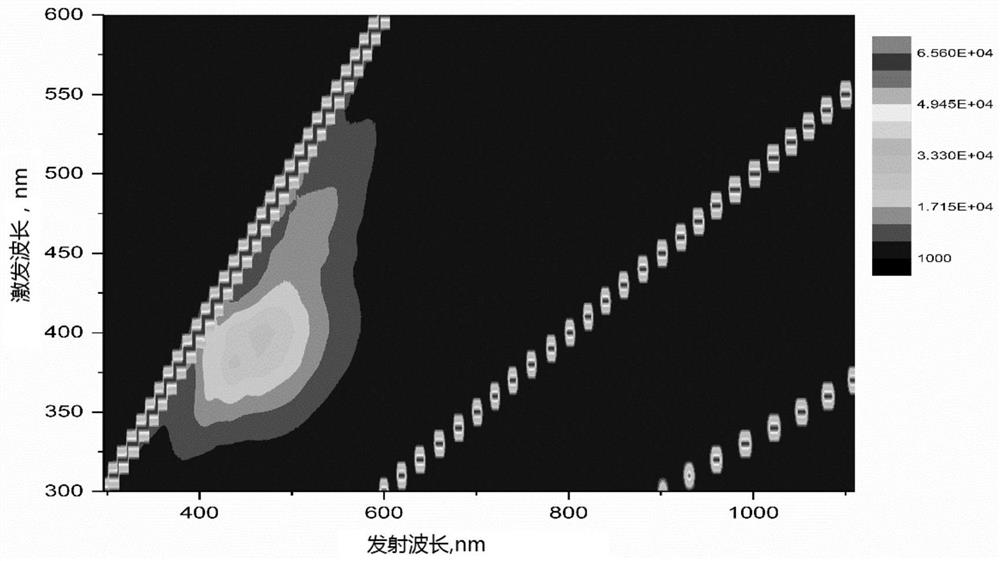

[0072] figure 2 is the ...

Embodiment 2

[0074] Add 2.5g of maleic anhydride, 0.89g of azobisisobutyronitrile, 2.6g of styrene, 40ml of acetone and 60ml of hexane into a 500mL three-necked flask. React in a water bath for 12 hours. After the reaction is completed, the obtained polymer emulsion suspension is centrifuged at a speed of 2000 rad / min for 20 minutes to obtain 4.6 g of polymer microspheres A2, corresponding to a polymer yield of 88%. The size of the polymer microsphere A2 is 500 nm.

[0075] The polymer microsphere A2 was carried out 1 According to H NMR measurement, based on the total molar weight of each structural unit in the polymer, the molar content of structural unit A derived from maleic anhydride is 48%, and the molar content of structural unit B derived from styrene is 52%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com