Maleic anhydride copolymer as well as preparation method and application thereof

A technology of maleic anhydride and copolymer, applied in the field of maleic anhydride copolymer and its preparation, can solve the problems of polluted environment, complex preparation process of maleic anhydride polymer and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The first aspect of the present invention provides a kind of preparation method of maleic anhydride copolymer, it is characterized in that, described method comprises the following steps:

[0026] (1) In an inert atmosphere, the polymerization monomer and the initiator are dissolved in the reaction medium to form a homogeneous solution;

[0027] (2) After the homogeneous solution is polymerized to obtain a copolymer emulsion suspension, the maleic anhydride copolymer is obtained after solid-liquid separation;

[0028] Wherein, the polymerized monomers are maleic anhydride and α-methylstyrene; based on the total weight of the polymerized monomers, the amount of the maleic anhydride is 29-63wt%, and the amount of the α-methylstyrene 36-72wt%;

[0029] The reaction medium is a mixture of compound I shown in formula (1) and compound II shown in formula (2);

[0030]

[0031] Among them, R 1 and R 2 Each is independently an alkyl group with 1 to 3 carbon atoms; R 3 ,...

Embodiment 1

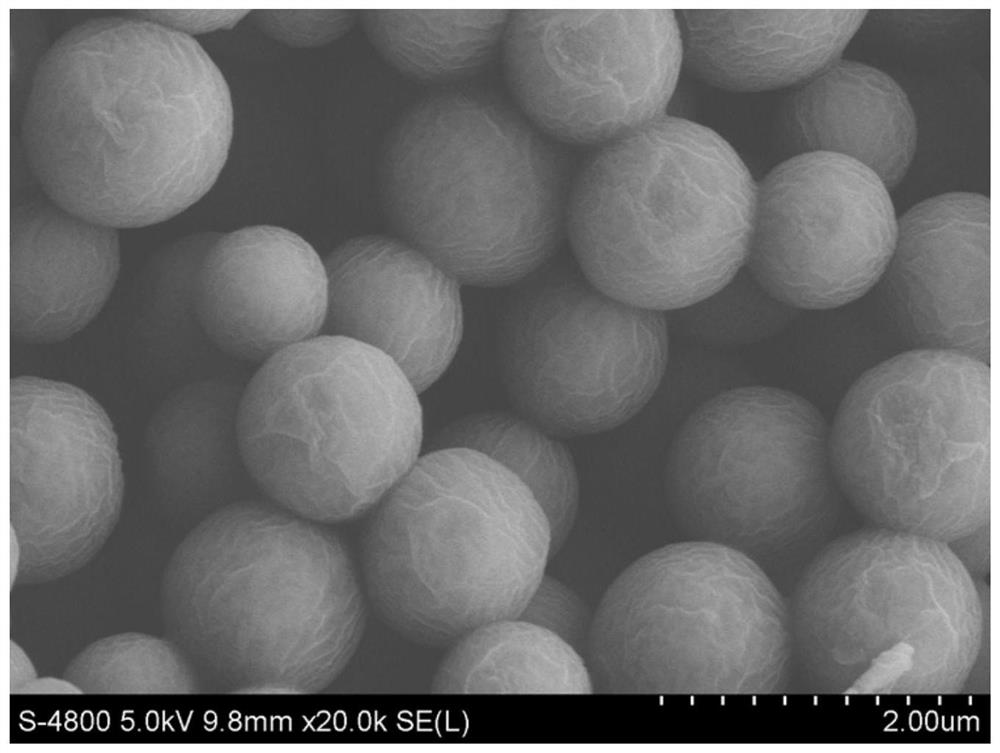

[0069] Add 5g maleic anhydride, 0.9g azobisisobutyronitrile, 6g α-methylstyrene, 40ml acetone and 60ml toluene into a 500mL three-necked flask. After the materials are mixed evenly, a homogeneous solution is obtained, and nitrogen gas is passed for 20 minutes. Move the three-necked flask into a water bath at 70°C and react for 5 hours. After the reaction is completed, the obtained polymer emulsion suspension is centrifuged at a speed of 1000 rad / min for 40 minutes to obtain 7.8 g of polymer A1, corresponding to a polymer yield of 71%. . The size of the polymer microsphere A1 is 1200 nm. Wherein, based on the total weight of the homogeneous solution, the concentration of the polymerizable monomer is 11.5wt%, and the concentration of the initiator is 0.9wt%.

[0070] The polymer microsphere A1 was carried out 1 H NMR measures, and records based on the total molar weight of each structural unit in the polymer, the molar content of the structural unit A provided by maleic anhydr...

Embodiment 2

[0075] Add 2.6g of maleic anhydride, 1g of azobisisobutyronitrile, 3g of α-methylstyrene, 40ml of acetone and 60ml of p-xylene into a 500mL three-necked flask. After the materials are mixed evenly, a homogeneous solution is obtained, and nitrogen gas is passed for 20 minutes. , moved the three-necked flask into a 90°C water bath, and reacted for 2 hours. After the reaction was completed, the obtained polymer emulsion suspension was centrifuged at a speed of 4000 rad / min for 10 minutes to obtain 4.2 g of polymer solids, corresponding to the polymer yield. 75%. The size of the polymer microsphere A2 is 500 nm. Wherein, based on the total weight of the homogeneous solution, the concentration of the polymerizable monomer is 6.3 wt%, and the concentration of the initiator is 1.1 wt%.

[0076] The polymer microsphere A2 was carried out 1 H NMR measures, and records based on the total molar weight of each structural unit in the polymer, the molar content of the structural unit A pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com