Porous easy-to-disperse multifunctional composite rubber auxiliary agent

A compound rubber and easy-to-disperse technology, applied in the field of rubber additives, can solve the problems of insufficient dispersion effect and reinforcing effect of carbon black, large difference in surface polarity between rubber and carbon black, easy self-aggregation of carbon black, etc. Polarity, improve carbon black properties, improve the effect of dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

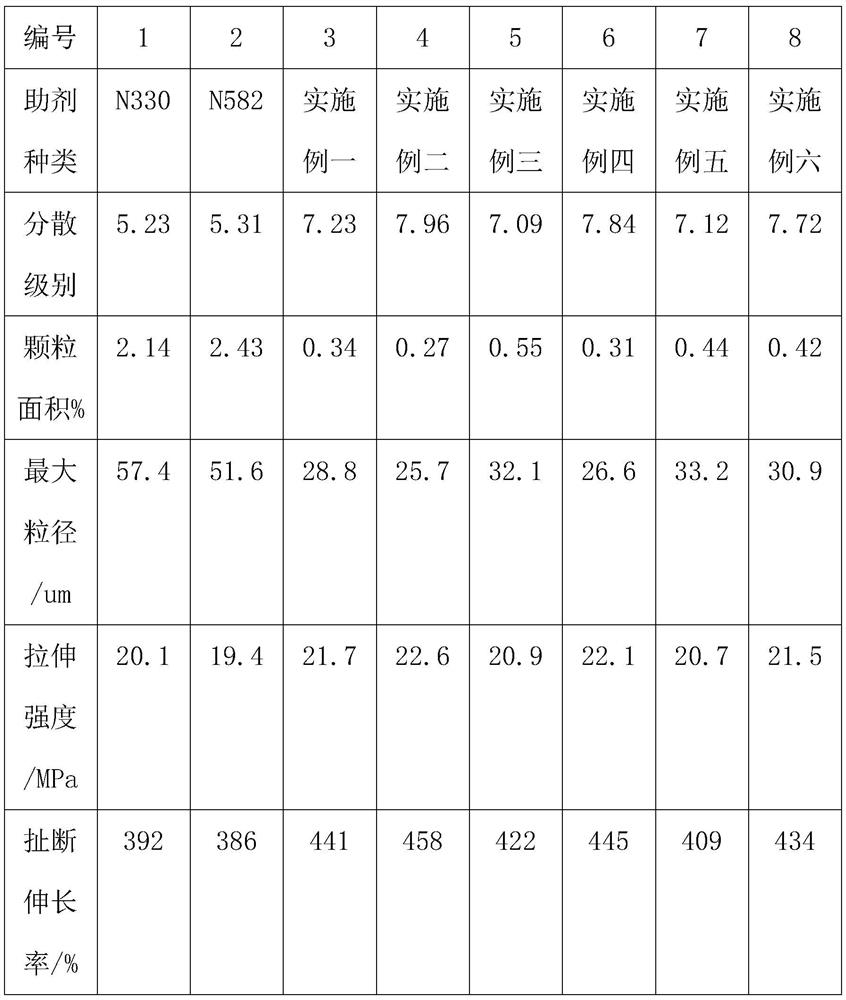

Examples

Embodiment 1

[0017] At room temperature, add carbon black N330, hot-melt cast iron slag and isolated products with a particle size of less than 200 μm into the three-dimensional mixer at a mass ratio of 1:0.9:0.1, and then add 0.8 times the sum of hot-melted cast iron slag and isolated products Add the coupling agent TESPT into the mixer twice, add 70% of the mass of the coupling agent TESPT for the first time, turn on the mixer and mix for 12 minutes, then add the remaining 30% of the coupling agent TESPT again, and mix for another 15 minutes , to obtain the crude product of mixed particles;

[0018] Put the crude mixed particles into the rotary vacuum dryer, control the speed of the dryer to 20r / 10min, vacuum the inside of the dryer to -0.08MPa, control the temperature at 50°C, keep the above conditions for 0.5h, and then slowly vacuum to -0.05 MPa, while slowly raising the temperature to 80°C, controlling the heating and vacuuming time at 1.5h, and then maintaining the above conditions ...

Embodiment 2

[0021] At room temperature, add carbon black N330, hot-melt cast iron slag and isolated products with a particle size of less than 200 μm into the three-dimensional mixer at a mass ratio of 1:1:0.2, and then add 1 times the sum of hot-melted cast iron slag and isolated products Add the coupling agent TESPT into the mixer twice, add 70% of the mass of the coupling agent TESPT for the first time, turn on the mixer and mix for 12 minutes, then add the remaining 30% of the coupling agent TESPT again, and mix for another 15 minutes , to obtain the crude product of mixed particles;

[0022] Put the crude mixed particles into the rotary vacuum dryer, control the speed of the dryer to 30r / 10min, vacuumize the inside of the dryer to -0.07MPa, control the temperature at 55°C, keep the above conditions for 0.5h, and then slowly vacuum to -0.05 MPa, while slowly raising the temperature to 85°C, controlling the heating and vacuuming time at 1h, and then maintaining the above conditions for...

Embodiment 3

[0025] At room temperature, add carbon black N330, hot-melt cast iron slag and isolated products with a particle size of less than 200 μm into the three-dimensional mixer at a mass ratio of 1:0.8:0.15, and then add 0.9 times the sum of hot-melted cast iron slag and isolated products Add the coupling agent TESPT into the mixer twice, add 70% of the mass of the coupling agent TESPT for the first time, start the mixer and mix for 15 minutes, then add the remaining 30% of the coupling agent TESPT again, and mix for another 12 minutes , to obtain the crude product of mixed particles;

[0026] Put the crude mixed particles into the rotary vacuum dryer, control the speed of the dryer to 25r / 10min, vacuum the inside of the dryer to -0.07MPa, control the temperature at 55°C, keep the above conditions for 0.5h, and then slowly vacuum to -0.05 MPa, while slowly raising the temperature to 85°C, controlling the heating and vacuuming time at 1.5h, and then maintaining the above conditions f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap