High-uniformity vanadium-titanium-based hydrogen storage alloy and preparation method thereof

A hydrogen storage alloy, vanadium-titanium-based technology, applied in the direction of chemical instruments and methods, hydrogen, non-metallic elements, etc., to achieve the effect of avoiding serious burning of the alloy, obvious technical advantages, and inhibiting macro-segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a high-uniformity V-Ti-Cr-Fe hydrogen storage alloy, comprising the following steps:

[0044] S1. FeV80-A alloy, MHT-95 titanium sponge, metal chromium, electrolytic manganese, and rare earth particles are selected as raw materials, wherein the particle size of FeV80 alloy is 5-15mm; the particle size of metal chromium is 5-20mm, and the particle size of rare earth particles is 10-30mm;

[0045] S2, charging, directly adding high-melting-point FeV80 alloy, sponge titanium, and metal chromium into the water-cooled copper crucible of the vacuum induction suspension melting furnace in batches, adding electrolytic manganese and metal cerium into the feeder of the vacuum induction suspension melting furnace, Then vacuumize to make the vacuum degree reach 0.001Pa, and then fill with argon to make the partial pressure reach about 500Pa;

[0046] S3. After the vacuum and partial pressure meet the requirements, start to increase the power in stages to heat...

Embodiment 2

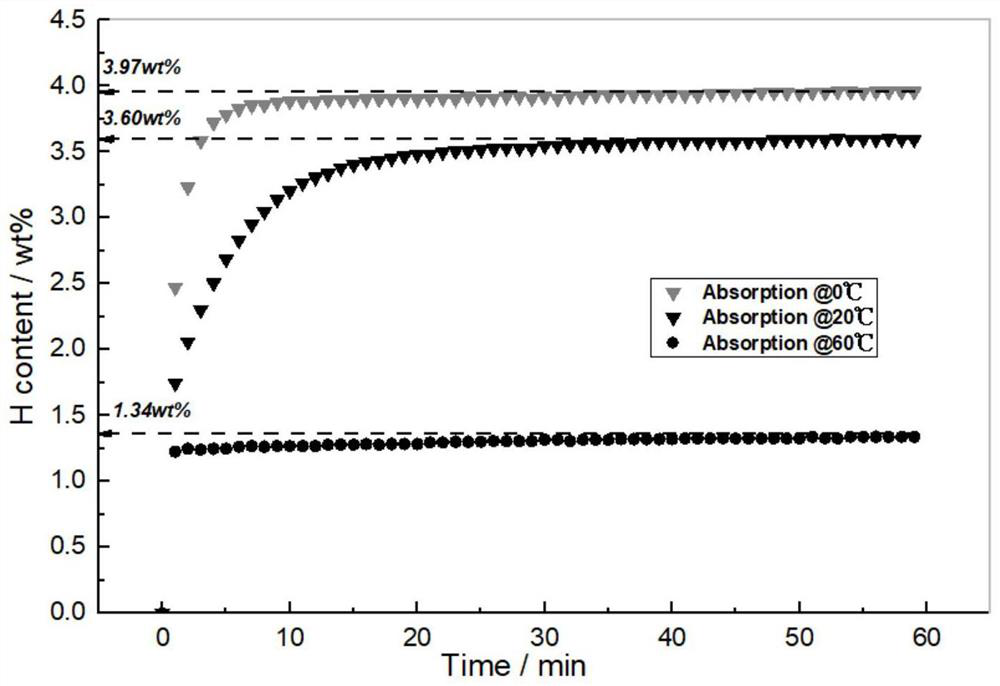

[0053] The preparation method of Example 2 is the same as that of Example 1, except that the rare earth is metal lanthanum, and the obtained hydrogen storage alloy is V a Ti b Cr c Fe d mn e La f Hydrogen storage alloys. Figure 4 is V a Ti b Cr c Fe d mn e La f Hydrogen absorption kinetics curves of hydrogen storage alloys. Depend on Figure 4 It can be obtained that the hydrogen storage alloy prepared in this embodiment can reach 3.50wt% hydrogen absorption at 20°C;

Embodiment 3

[0055] Embodiment 3 is the same as Embodiment 1, and its difference is that no rare earth is added, and the hydrogen storage alloy obtained is V a Ti b Cr c Fe d Hydrogen storage alloys. Figure 5 is V a Ti b Cr c Fe d Hydrogen absorption kinetics curves of hydrogen storage alloys. Depend on Figure 5 It can be obtained that the hydrogen absorption amount can reach 3.49wt% at 20°C, and the hydrogen absorption time of the alloy without rare earth addition is significantly longer than that of the alloy with rare earth addition. The addition of rare earth can improve the hydrogen absorption channel of the alloy and increase the hydrogen absorption speed of the alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com