Method for improving performance of myofibrillar protein

A myofibrillar protein and performance technology, which is applied in the field of myofibrillar protein performance improvement, can solve the problem of myofibrillar protein being susceptible to oxidation attack, improve oxidation stability and gel forming ability, reduce sulfhydryl group and solubility Loss, increase in gel strength and water-holding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

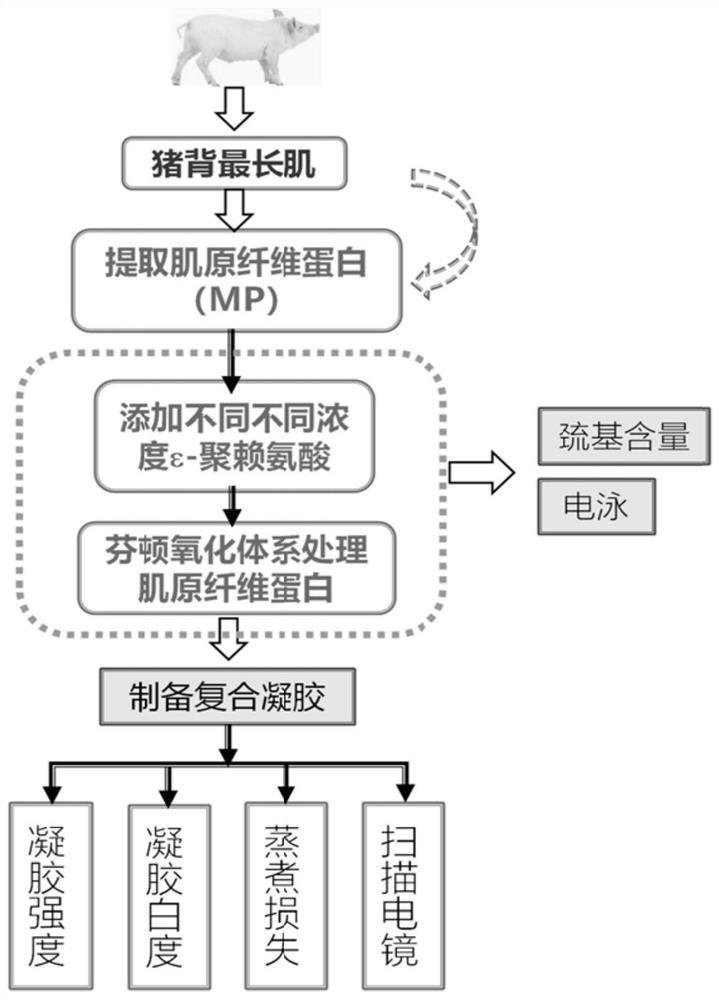

[0059] Embodiment 1 provides a method for improving the performance of myofibrillar protein, comprising the following steps:

[0060] Step 1. Remove the fat and connective tissue from the outer loin, cut it into strips and weigh it for later use. Place the processed strips of loin in a tissue masher, add four times the volume of stiffening liquid, and homogenize and smash it. After crushing and centrifugation, the primary precipitate was obtained. Add four times the volume of stiffening fluid to the primary sediment, repeat homogenization, mashing, and centrifugation 3-4 times to obtain a sediment. Four times the volume of NaCl solution was added to the precipitate, and after homogenizing and stirring, filtered through four layers of gauze to obtain a filtrate. Using HCl solution, the pH of the filtrate was adjusted to 6.20-6.25. After centrifugation again, a precipitate was obtained. is MP; wherein, the precipitate is MP, that is, the myofibrillar protein paste is obtained; ...

Embodiment 2

[0064] A method for improving the performance of myofibrillar protein is provided in embodiment 2, comprising the following steps:

[0065] Step 1. Remove the fat and connective tissue from the outer loin, cut it into strips and weigh it for later use. Place the processed strips of loin in a tissue masher, add four times the volume of stiffening liquid, and homogenize and smash it. After crushing and centrifugation, the primary precipitate was obtained. Add four times the volume of stiffening fluid to the primary sediment, repeat homogenization, mashing, and centrifugation 3-4 times to obtain a sediment. Four times the volume of NaCl solution was added to the precipitate, and after homogenizing and stirring, filtered through four layers of gauze to obtain a filtrate. Using HCl solution, the pH of the filtrate was adjusted to 6.20-6.25. After centrifugation again, a precipitate was obtained. is MP; wherein, the precipitate is MP, that is, the myofibrillar protein paste is obta...

Embodiment 3

[0069] A method for improving the performance of myofibrillar protein is provided in embodiment 3, comprising the following steps:

[0070] Step 1. Remove the fat and connective tissue from the outer loin, cut it into strips and weigh it for later use. Place the processed strips of loin in a tissue masher, add four times the volume of stiffening liquid, and homogenize and smash it. After crushing and centrifugation, the primary precipitate was obtained. Add four times the volume of stiffening fluid to the primary sediment, repeat homogenization, mashing, and centrifugation 3-4 times to obtain a sediment. Four times the volume of NaCl solution was added to the precipitate, and after homogenizing and stirring, filtered through four layers of gauze to obtain a filtrate. Using HCl solution, the pH of the filtrate was adjusted to 6.20-6.25. After centrifugation again, a precipitate was obtained. is MP; wherein, the precipitate is MP, that is, the myofibrillar protein paste is obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com