Silver phosphate and carbon nitride composite photocatalytic filter material and preparation method thereof

A silver phosphate carbon nitride and composite photocatalysis technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle filtration, etc., can solve the problem of uneven distribution of TiO2 in photocatalytic filter materials, low sunlight utilization rate, and light source utilization rate. low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

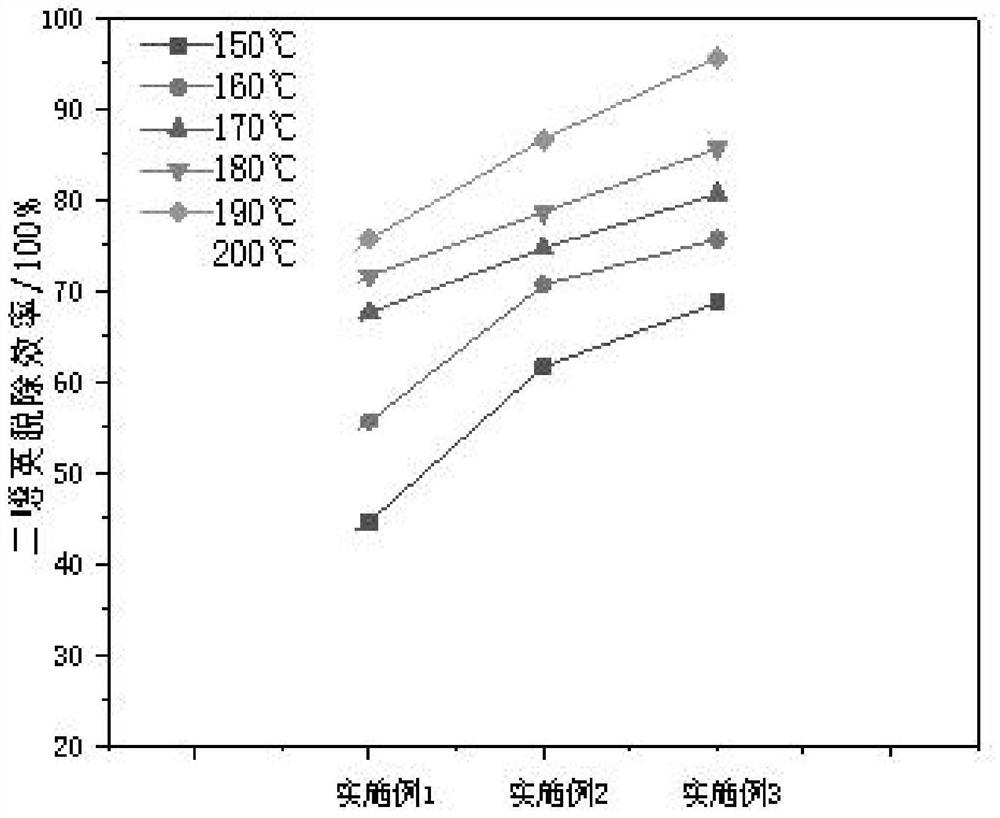

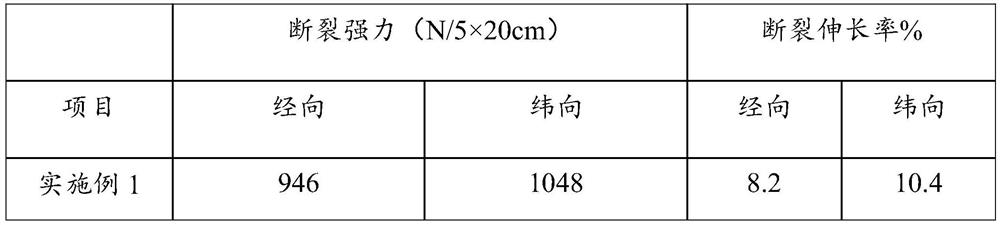

Embodiment 1

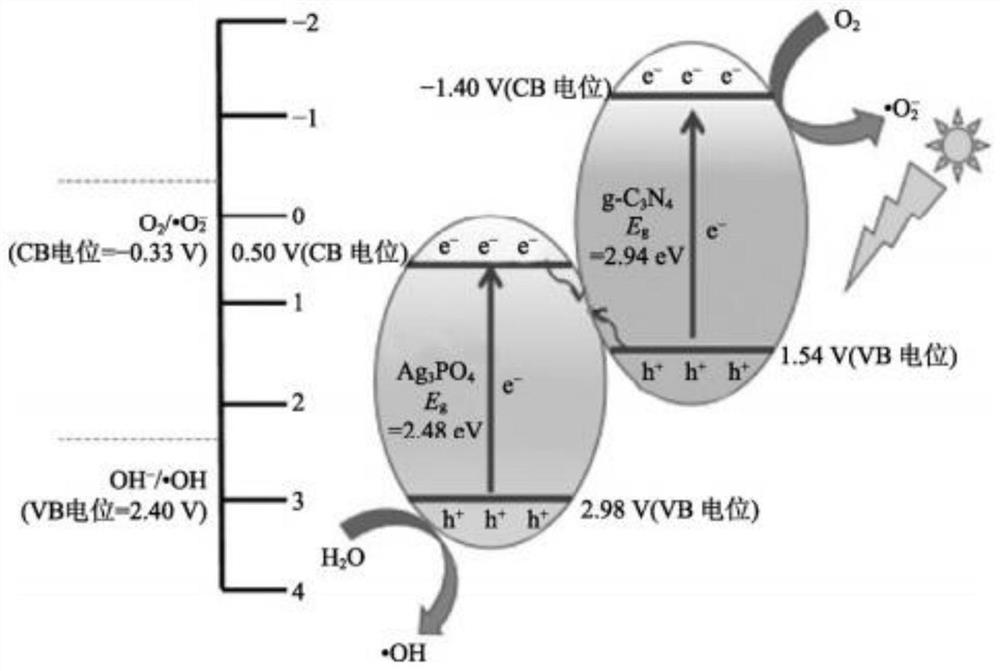

[0036]A silver phosphate carbon nitride composite photocatalytic filter material, the silver phosphate carbon nitride composite photocatalytic filter material includes a bottom layer, a surface layer and a base cloth layer, wherein the bottom layer and the surface layer are PTFE needle-punched filter materials, and the base cloth The layer is PTFE base cloth, and Ag is evenly loaded in PTFE fibers. 3 PO 4 / g -C 3 N 4 Composite photocatalyst;.

[0037] The production raw materials of silver phosphate carbon nitride composite photocatalytic filter material include by weight: 2 parts of silver nitrate, 2 parts of melamine, 1 part of sodium dihydrogen phosphate, 1 part of binder, 6 parts of PTFE emulsion and 15 parts of PTFE short fiber.

[0038] A preparation method of silver phosphate carbon nitride composite photocatalytic filter material, the preparation method comprises the following steps:

[0039] S1: Preparation of silver nitrate solution

[0040] Silver nitrate was ...

Embodiment 2

[0054] A silver phosphate carbon nitride composite photocatalytic filter material, the silver phosphate carbon nitride composite photocatalytic filter material includes a bottom layer, a surface layer and a base cloth layer, wherein the bottom layer and the surface layer are PTFE needle-punched filter materials, and the base cloth The layer is PTFE base cloth, and Ag is evenly loaded in PTFE fibers. 3 PO 4 / g -C 3 N 4 Composite photocatalyst;

[0055] The production raw materials of silver phosphate carbon nitride composite photocatalytic filter material include by weight: 4 parts of silver nitrate, 4 parts of melamine, 2 parts of sodium dihydrogen phosphate, 1.5 parts of binder, 8 parts of PTFE emulsion and 20 parts of PTFE short fiber.

[0056] A preparation method of silver phosphate carbon nitride composite photocatalytic filter material, the preparation method comprises the following steps:

[0057] S1: Preparation of silver nitrate solution

[0058] Silver nitrate ...

Embodiment 3

[0072] A silver phosphate carbon nitride composite photocatalytic filter material, the silver phosphate carbon nitride composite photocatalytic filter material includes a bottom layer, a surface layer and a base cloth layer, wherein the bottom layer and the surface layer are PTFE needle-punched filter materials, and the base cloth The layer is PTFE base cloth, and Ag is evenly loaded in PTFE fibers. 3 PO 4 / g -C 3 N 4 Composite photocatalyst;

[0073] The production raw materials of silver phosphate carbon nitride composite photocatalytic filter material include by weight: 6 parts of silver nitrate, 6 parts of melamine, 1.5 parts of sodium dihydrogen phosphate, 1.3 parts of binder, 7 parts of PTFE emulsion and 10 parts of PTFE short fiber.

[0074] A preparation method of silver phosphate carbon nitride composite photocatalytic filter material, the preparation method comprises the following steps:

[0075] S1: Preparation of silver nitrate solution

[0076] Silver nitrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com