Printing and dyeing tail water deep treatment and reuse process

A technology of advanced treatment and tail water, applied in the field of printing and dyeing tail water treatment, can solve the problems of low bioavailability, low mass transfer efficiency, chemical refractory degradation, etc., and achieve the effect of filling the technical gap, safe and convenient operation, and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

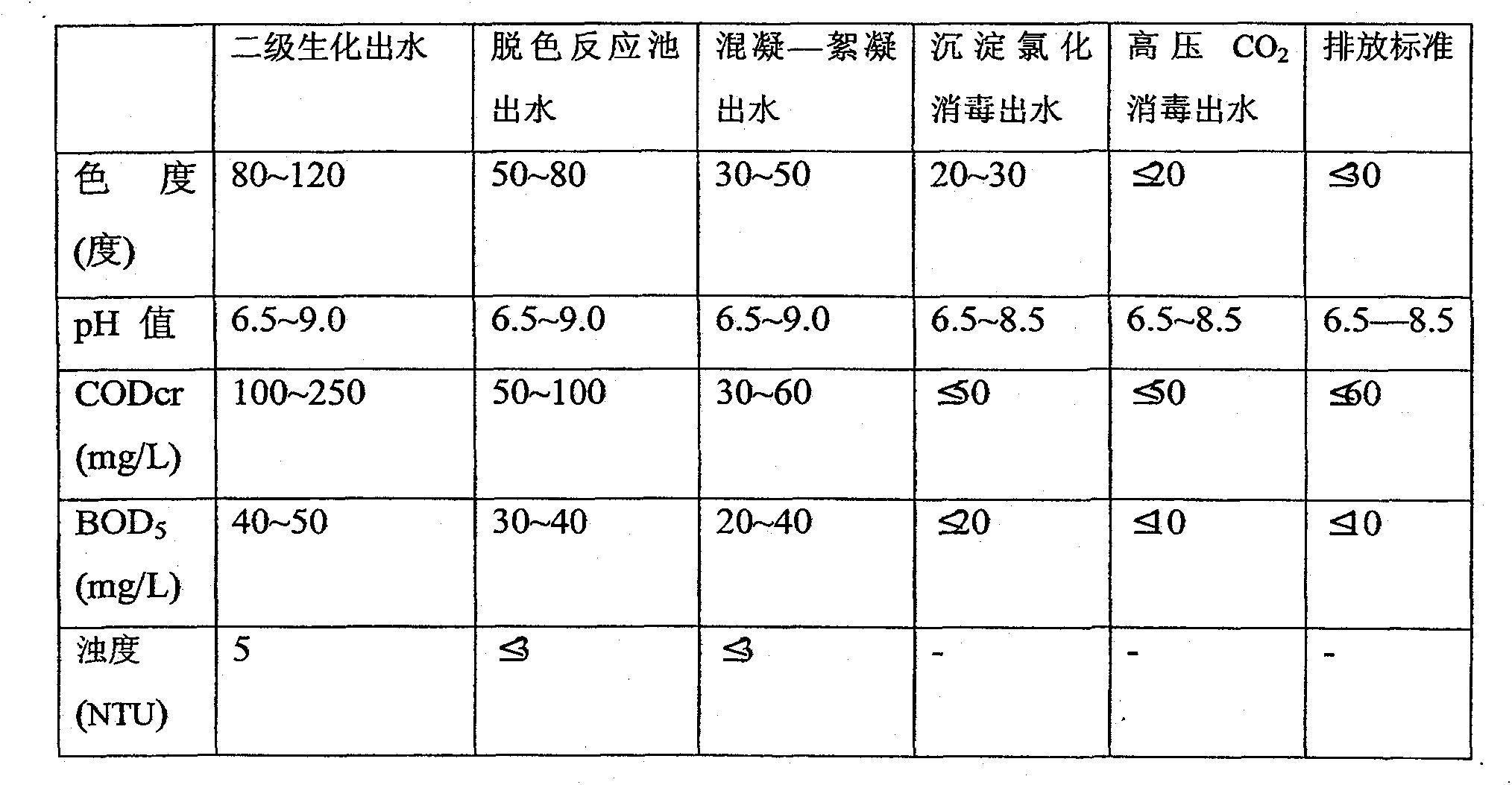

[0039] In this example, the sewage discharged from a printing and dyeing factory in Nanjing, which is inferior to category V, is subjected to advanced treatment to meet the "Urban Sewage Recycling Industrial Water Quality" (GB / T19923-2005), with a daily treatment capacity of 10 tons.

[0040] The advanced sewage treatment steps of this embodiment are as follows:

[0041] a) Collect the printing and dyeing tail water after secondary biochemical treatment; remove mechanical impurities of different sizes in the polluted water, such as textile fibers, dregs, sand, stones, wood chips, fur, etc.;

[0042] b) Decolorization reaction pool

[0043] The water obtained in step a) is introduced into the decolorization reaction tank, and a nanometer zero-valent iron powder layer and a stirrer with a thickness of 12cm are provided in the decolorization reaction tank. The nanometer zero-valent iron powder is granular, and the particles are spherical. The diameter is less than 100nm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com