Preparation method of dust removal and VOCS removal synergistic photocatalysis filter material and prepared filter material

A technology of photocatalysis and filter materials, applied in the direction of catalyst activation/preparation, chemical instruments and methods, separation methods, etc., can solve the problem of uneven distribution of TiO2 in photocatalytic filter materials, and achieve good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

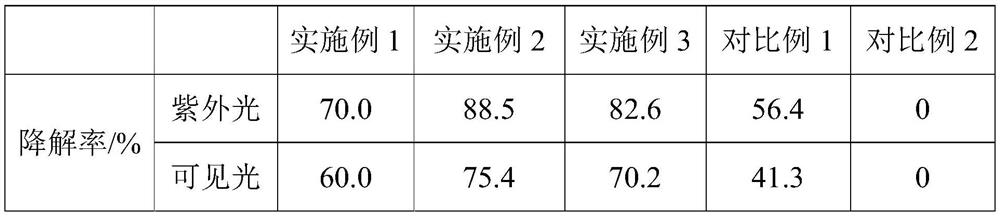

Examples

Embodiment 1

[0038] A preparation method of a dedusting and VOCS synergistic photocatalytic filter material, comprising the following steps:

[0039] (1) Preparation of silver nitrate solution

[0040] Weigh 10-20g of silver nitrate, put it in 390mL of water and stir until dissolved;

[0041] (2) Preparation of sodium dihydrogen phosphate / PTFE composite film-forming dipping solution

[0042] Weigh 5-10g of sodium dihydrogen phosphate and dissolve it in 390mL of water, then add 30g of PTFE emulsion and 5g of epoxy resin, and stir on a magnetic stirrer at a speed of 500r / min for 30min to prepare sodium dihydrogen phosphate for PTFE non-woven fabric / PTFE composite film-forming dipping solution;

[0043] (3) Preparation of needle felt

[0044] The PTFE short fibers are opened, mixed, finely opened, carded, netted, added with PTFE base cloth, and needled to make semi-finished needled felts. The unit weight of the semi-finished needled felts is controlled at 780-830g / m 2 ;

[0045] (4) The...

Embodiment 2

[0051] A preparation method of a dedusting and VOCS synergistic photocatalytic filter material, comprising the following steps:

[0052] (1) Preparation of silver nitrate solution

[0053] Weigh 20-30g silver nitrate, put it in 390mL water and stir until dissolved;

[0054] (2) Preparation of sodium dihydrogen phosphate / PTFE composite film-forming dipping solution

[0055] Weigh 10-15g of sodium dihydrogen phosphate and dissolve it in 390mL of water, then add 30g of PTFE emulsion and 5g of adhesive, and stir on a magnetic stirrer at a speed of 500r / min for 30min to prepare sodium dihydrogen phosphate for PTFE nonwoven fabric / PTFE composite film-forming dipping solution;

[0056] (3) Preparation of needle felt

[0057] The PTFE short fibers are opened, mixed, finely opened, carded, netted, added with PTFE base cloth, and needled to make semi-finished needled felts. The unit weight of the semi-finished needled felts is controlled at 780-830g / m 2 ;

[0058] (4) The first st...

Embodiment 3

[0064] A preparation method of a dedusting and VOCS synergistic photocatalytic filter material, comprising the following steps:

[0065] (1) Preparation of silver nitrate solution

[0066] Weigh 30-40g of silver nitrate, put it in 390mL of water and stir until dissolved;

[0067] (2) Preparation of sodium dihydrogen phosphate / PTFE composite film-forming dipping solution

[0068] Weigh 15-20g of sodium dihydrogen phosphate and dissolve it in 390mL of water, then add 30g of PTFE emulsion and 5g of adhesive, and stir on a magnetic stirrer for 30min at a speed of 500r / min to prepare sodium dihydrogen phosphate for PTFE nonwoven fabric / PTFE composite film-forming dipping solution;

[0069] (3) Preparation of needle felt

[0070] The PTFE short fibers are opened, mixed, finely opened, carded, netted, added with PTFE base cloth, and needled to make semi-finished needled felts. The unit weight of the semi-finished needled felts is controlled at 780-830g / m 2 ;

[0071] (4) The fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com