Method for preparing lithium adsorbent through in-situ growth on alumina ball and lithium adsorbent

An in-situ growth and lithium adsorption technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as difficult industrial operation, poor fluidity and permeability, and loss of adsorbent, so as to improve adsorption capacity and facilitate adsorption , is conducive to the effect of mass transfer and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

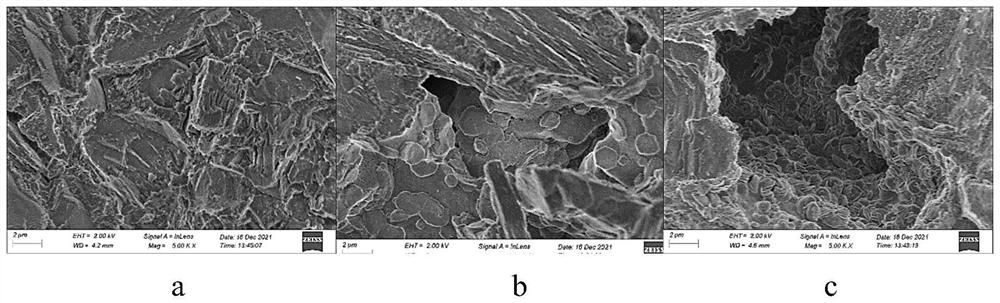

Embodiment 1

[0048] Al 2 o 3 A method for preparing a lithium adsorbent by in situ growth on a ball, comprising the following steps:

[0049] S1. Take white Al with a particle diameter of 2mm 2 o 3 2kg of pellets were soaked in 2L of hydrochloric acid solution with pH = 1 for 1 hour, and then etched Al with deionized water 2 o 3 The pellets were washed 3 times, and Al 2 o 3 The pellets were fully dried in an oven at 120°C for 4 hours to make Al 2 o 3 The water in the ball body is fully removed;

[0050] S2. take out the dried Al obtained in step S1 2 o 3 Spray the ball with 800mL LiCl solution with a concentration of 1mol / L on 2 o 3 Wet it on the ball, no flowable liquid can appear during the wetting process, and then put the wet LiCl-Al 2 o 3 Place the pellets in an oven at 120°C for 4 hours to fully remove the moisture in the body and obtain dry LiCl-Al 2 o 3 small ball;

[0051] S3. Use 400mL of AlCl with a substance concentration of 2mol / L 3 The solution is sprayed on...

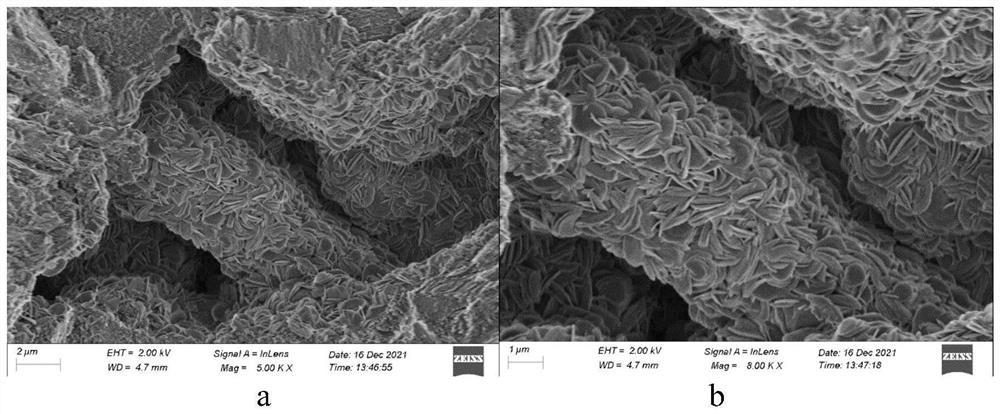

Embodiment 2

[0056] Al 2 o 3 A method for preparing a lithium adsorbent by in situ growth on a ball, comprising the following steps:

[0057] S1. Take white Al with a particle diameter of 1.5mm 2 o 3 1 kg of pellets, soaked in 1 L of hydrochloric acid solution with pH = 1 for 1 h, and then etched Al with deionized water 2 o 3 The pellets were washed 3 times, and Al 2 o 3 The pellets were fully dried in an oven at 130°C for 3 hours to make Al 2 o 3 The water in the ball body is fully removed;

[0058] S2. take out the dried Al obtained in step S1 2 o 3 Spray the ball on the Al 2 o 3 Wet it on the ball, no flowable liquid can appear during the wetting process, and then put the wet LiCl-Al 2 o 3 Place the pellets in an oven at 130°C for 3 hours to fully dry the moisture in the body to obtain dry LiCl-Al 2 o 3 small ball;

[0059] S3. Use 200mL of AlCl with a substance concentration of 2mol / L 3 The solution is sprayed on the dry LiCl-Al obtained in step S2 2 o 3 On the ball...

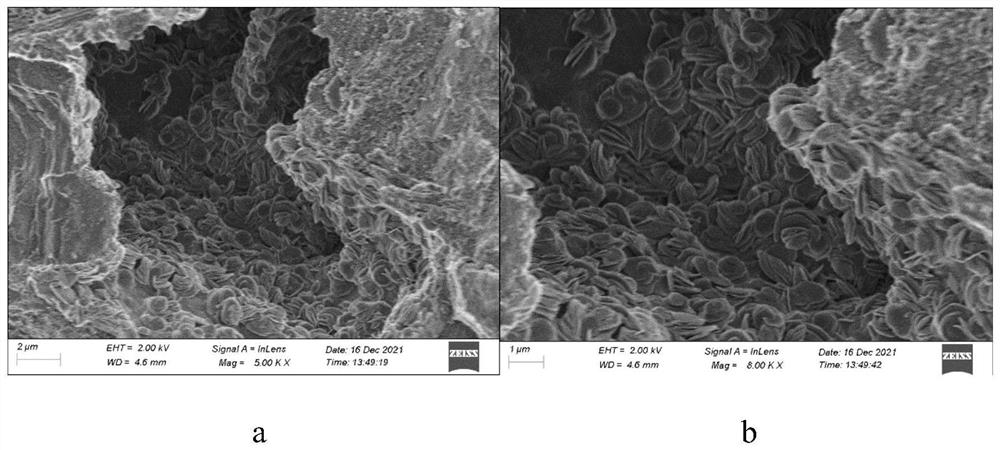

Embodiment 3

[0064] Al 2 o 3 A method for preparing a lithium adsorbent by in situ growth on a ball, comprising the following steps:

[0065] S1. Take white Al with a particle diameter of 1.5mm 2 o 3 1.5 kg of pellets were soaked in 1.5 L of hydrochloric acid solution with pH = 1 for 2 hours, and then etched Al with deionized water 2 o 3 The pellets were washed 3 times, and Al 2 o 3 The pellets were fully dried in an oven at 150°C for 5 hours to make Al 2 o 3 The water in the ball body is fully removed;

[0066] S2. take out the dried Al obtained in step S1 2 o 3 Spray the ball on the Al 2 o 3 Wet it on the ball, no flowable liquid can appear during the wetting process, and then put the wet LiCl-Al 2 o 3 Place the pellets in an oven at 130°C for 3 hours to fully dry the moisture in the body to obtain dry LiCl-Al 2 o 3 small ball;

[0067] S3. Use 300mL of AlCl with a substance concentration of 2mol / L 3 The solution is sprayed on the dry LiCl-Al obtained in step S2 2 o 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com