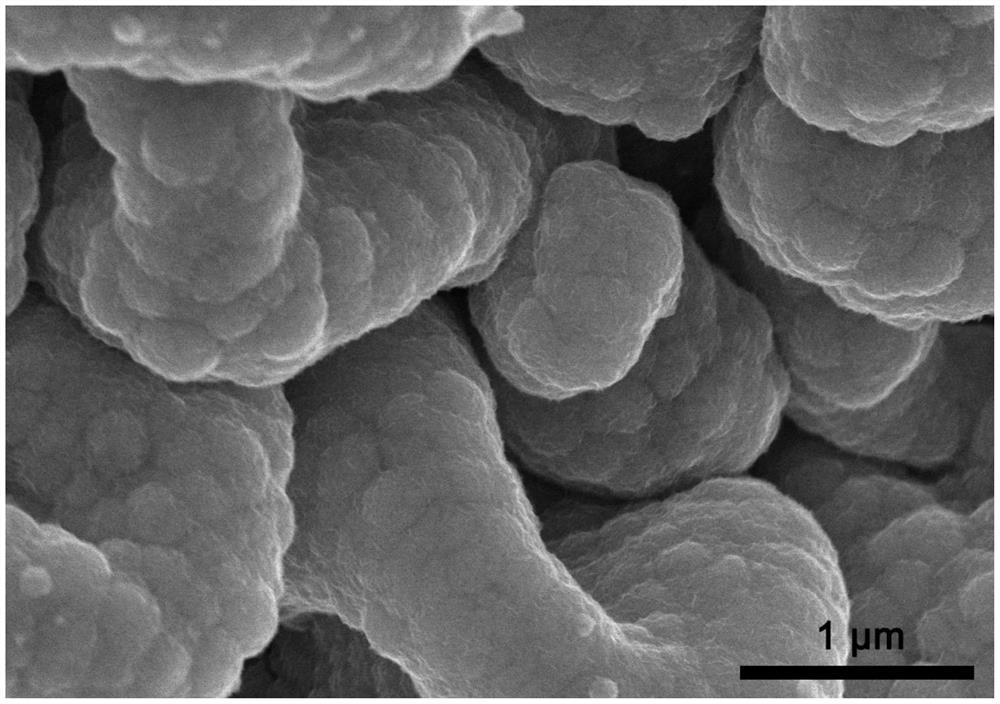

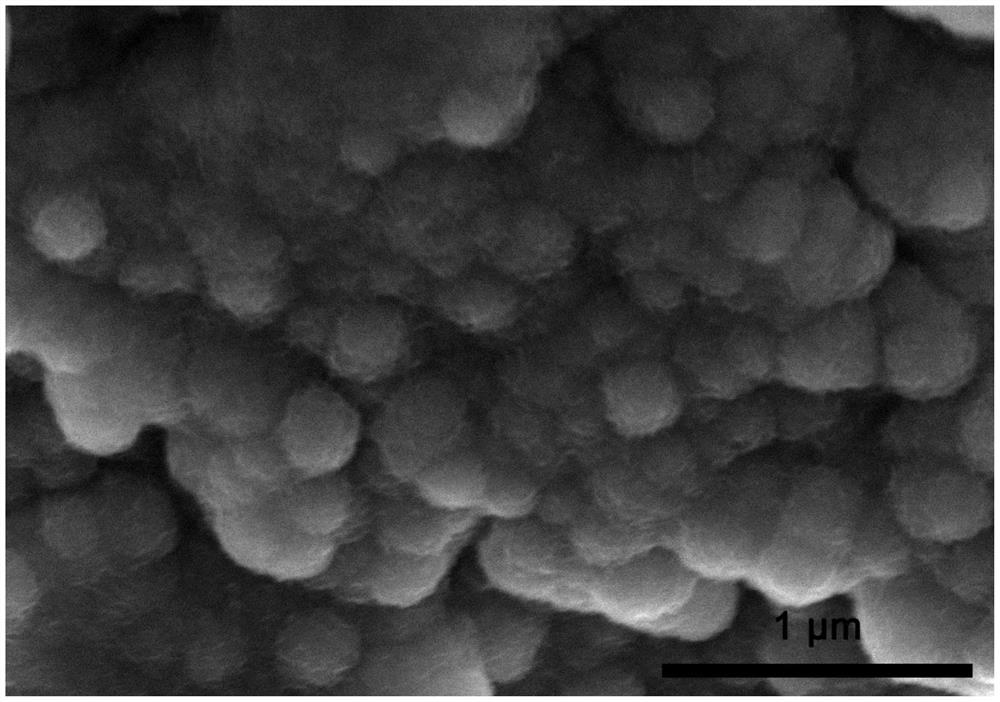

Bimetal-based composite catalyst with fluffy structure as well as preparation method and application of bimetal-based composite catalyst

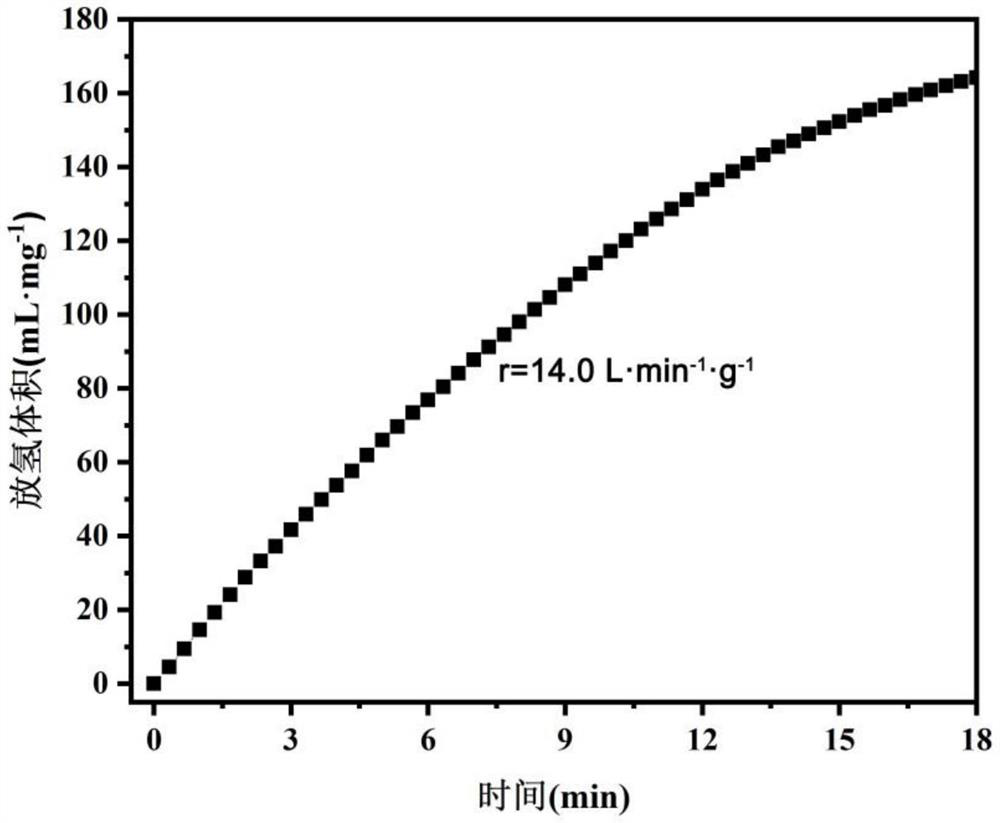

A composite catalyst, bimetallic technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of limited storage, high price, application limitations, etc. Achieving the effect of increased surface area, ease of operation, and improved reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Weigh 0.05g g-C 3 N 4 Place in 80mL deionized water and ultrasonically disperse for 30min to form dispersion system A;

[0045]2) Add 0.005mol ferrous sulfate heptahydrate and 0.005mol cobalt chloride hexahydrate to the dispersion system A in the above step 1) and stir to make them all dissolve to form dispersion system B;

[0046] 3) Add 4.5 g of glycine to the dispersion system B formed in the above step 2), stir to dissolve it completely, adjust the pH value to 12, and obtain dispersion system C;

[0047] 4) Slowly add sodium borohydride into the dispersion system C, and with magnetic stirring, to obtain solution D. After the solution D is kept at a temperature of 25° C., add pretreated nickel foam to continue the reaction;

[0048] 5) After the reaction is over, the nickel foam is taken out, washed with deionized water and ethanol successively and dried in vacuum to obtain a bimetallic matrix composite catalyst;

[0049] Wherein, step 4) in the solution D, the...

Embodiment 2

[0055] 1) Weigh 0.05g g-C 3 N 4 Place in 80mL deionized water and ultrasonically disperse for 30min to form dispersion system A;

[0056] 2) Add 0.005mol ferrous sulfate heptahydrate and 0.005mol cobalt chloride hexahydrate to the dispersion system A in the above step 1) and stir to make them all dissolve to form dispersion system B;

[0057] 3) Add 4.5 g of glycine to the dispersion system B formed in the above step 2), stir to dissolve it completely, adjust the pH value to 12, and obtain dispersion system C;

[0058] 4) Slowly add sodium borohydride into the dispersion system C, and with magnetic stirring, to obtain solution D. After the solution D is kept at a temperature of 25° C., add pretreated nickel foam to continue the reaction;

[0059] 5) After the reaction is over, the nickel foam is taken out, washed with deionized water and ethanol successively and dried in vacuum to obtain a bimetallic matrix composite catalyst;

[0060] Wherein, step 4) in the solution D, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com