Catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, applied in catalyst activation/preparation, catalytic cracking, physical/chemical process catalysts, etc., can solve the problems of high energy consumption, high loss, and complex catalytic cracking catalyst preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In order to achieve the above object, a first aspect of the present invention provides a method for preparing a catalyst cracking catalyst, the method comprising:

[0045] 1) making the sodium-type molecular sieve and the solution containing the ammonium root ion carry out the first ion exchange reaction, and obtain the molecular sieve after the ammonium root ion exchange;

[0046] 2) Under microwave conditions, the ammonium ion-exchanged molecular sieve and the solution containing rare earth element ions are subjected to a second ion exchange reaction to obtain a molecular sieve containing rare earth elements;

[0047] 3) After beating the rare earth element-containing molecular sieve obtained in step 2) with clay, binder, water and inorganic acid to form a colloid, the obtained colloid is dried and calcined.

[0048] The inventors of the present invention have found that, firstly, the ammonium ion is used to exchange the sodium ions in the sodium-type molecular sieve,...

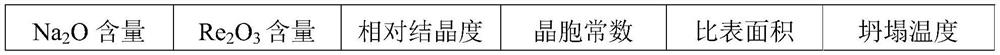

Embodiment 1

[0106] 1) NaY molecular sieve is mixed with ammonium ion concentration in ammonium chloride aqueous solution of 2mol / L, with respect to 1L ammonium chloride aqueous solution, the addition amount of NaY molecular sieve is 200g, adjusts pH with dilute hydrochloric acid solution (concentration is 5% by weight) After reaching 5.5, heat the above mixed solution to 70°C, and stir at this temperature for 30 minutes, then filter, wash the product with 5 times the volume of deionized water after filtration, and then dry it at 150°C for 6 hours to obtain ammonium ion-exchanged Molecular sieve;

[0107] 2) the molecular sieve after the ammonium ion exchange that step 1) obtains and total concentration are lanthanum chloride and cerium chloride aqueous solution (wherein, lanthanum chloride concentration is 0.2mol / L, and cerium chloride concentration is 0.3mol / L) mixing and beating, relative to 1L lanthanum chloride aqueous solution, the amount of molecular sieve after ammonium ion exchang...

Embodiment 2

[0115] 1) NaY molecular sieve is mixed with ammonium ion concentration in ammonium chloride aqueous solution of 2mol / L, with respect to 1L ammonium chloride aqueous solution, the addition amount of NaY molecular sieve is 200g, adjusts pH with dilute hydrochloric acid solution (concentration is 5% by weight) After reaching 6, heat the above mixed solution to 60°C, and stir at this temperature for 20 minutes, then filter, wash the obtained product with 5 times the volume of deionized water after filtration, and then dry at 150°C for 6 hours to obtain ammonium ion exchanged Molecular sieve;

[0116] 2) the molecular sieve after the ammonium ion exchange that step 1) obtains and total concentration are lanthanum chloride and cerium chloride aqueous solution (wherein, lanthanum chloride concentration is 0.04mol / L, and cerium chloride concentration is 0.06mol / L) mixing and beating, relative to 1L lanthanum chloride aqueous solution, the amount of molecular sieve after ammonium ion e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com