A kind of preparation method of flexible composite lithium metal thin film and lithium ion battery

A composite metal and metal lithium technology, which is applied in the direction of battery electrodes, secondary batteries, circuits, etc., to achieve the effects of simple preparation process, high safety, and saving production and preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

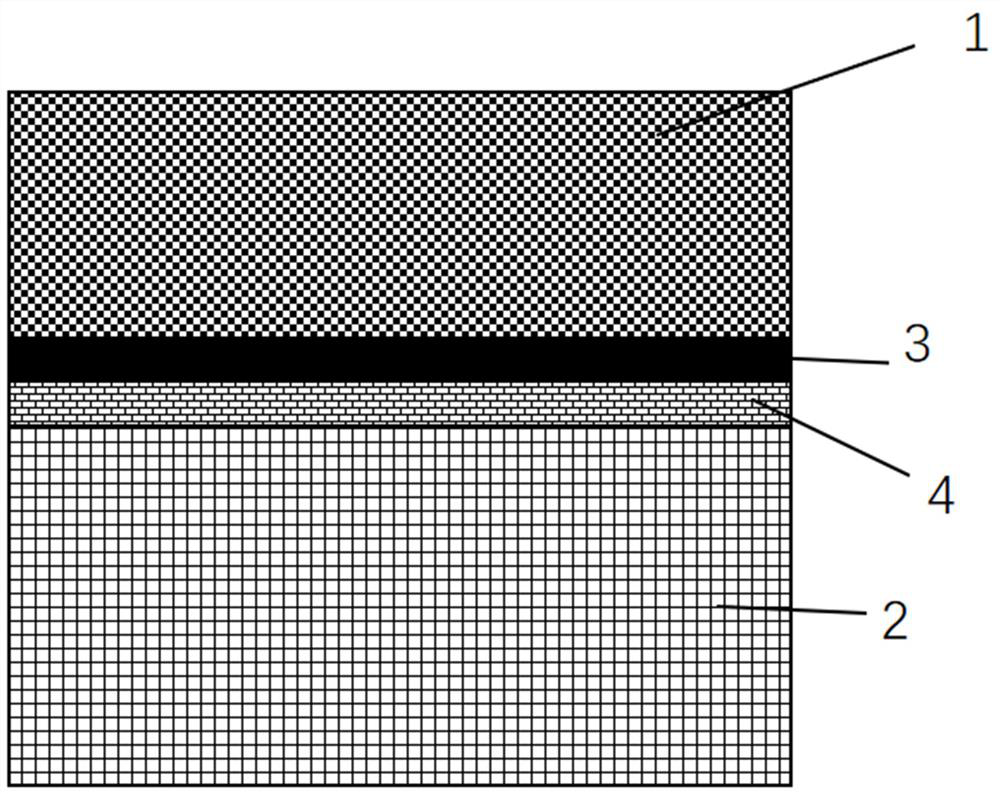

[0050] A flexible composite lithium metal film 4, comprising the following components:

[0051] Polyethylene 3%

[0052] Superconducting carbon black 12%

[0053] Lithium particles 85%

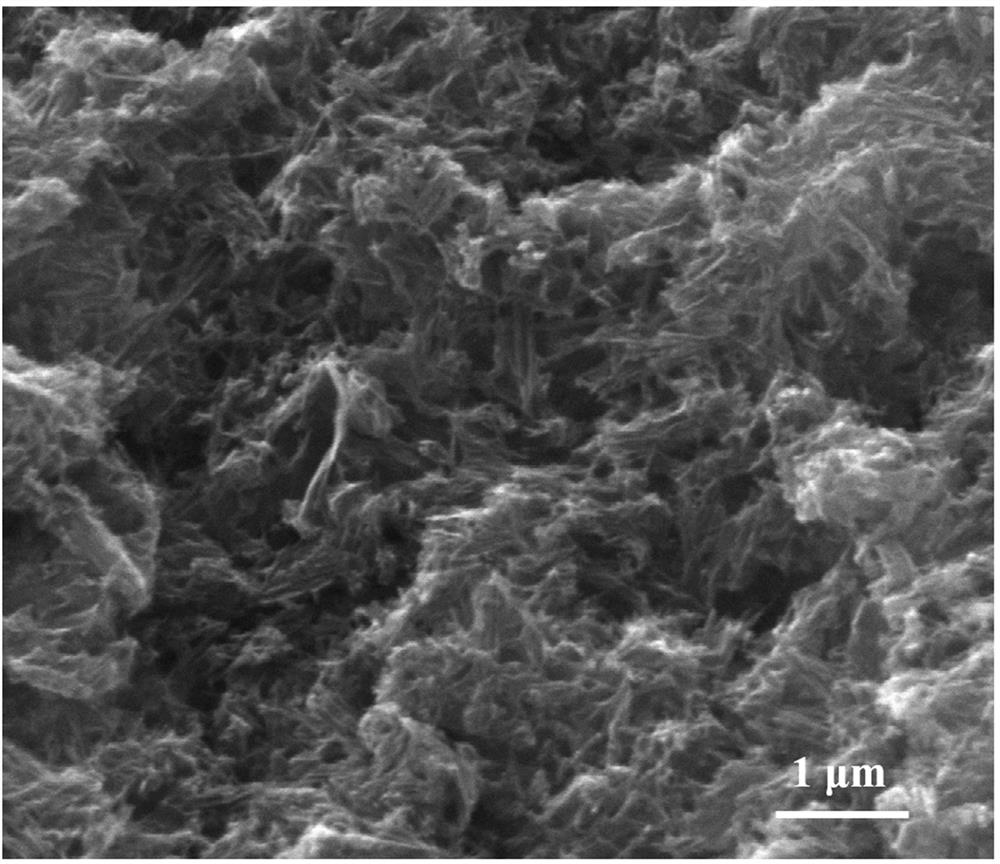

[0054] Mix the above-mentioned substances according to the above ratio, pass in argon gas, and stir for 25 minutes through the stirring rod, wherein the stirring rod rotates at 3000rpm, heat to 250°C, and keep at this temperature for 2 hours to obtain a fluid mixture in a molten state. Pass the fluid mixture through It is extruded by a twin-screw extruder, formed into a sheet film by a sheet head, and then rolled by a three-roll calender. Among them, the model of polyvinyl chloride is WS-1000S, and the rolling pressure is 350kg. The final flexible composite lithium metal film 4 has a thickness of 2 μm, a tensile strength of 100 mPa, and an elongation at break of 7%.

Embodiment 2

[0056] A flexible composite lithium metal film 4, comprising the following components:

[0057] PVC 5%

[0058] Carbon Fiber 5%

[0060] Mix the above-mentioned substances according to the above-mentioned ratio, pass in argon gas, and stir for 30 minutes through a stirring rod, wherein the stirring rod rotates at 2500 rpm, heat to 250°C, and keep at this temperature for 2 hours to obtain a fluid mixture in a molten state. Pass the fluid mixture through Extruded by a twin-screw extruder, formed into a sheet film by a sheet head, and then calendered and rolled by a three-roller calender. Among them, the model of polyethylene is HC7260, and the size of the lithium powder used is 20 μm. The pressing force was 300kg, and the roller distance was 5 μm. Finally, the flexible composite lithium metal film 4 was obtained with a thickness of 7 μm, a tensile strength of 137 mPa, and an elongation at break of 9%.

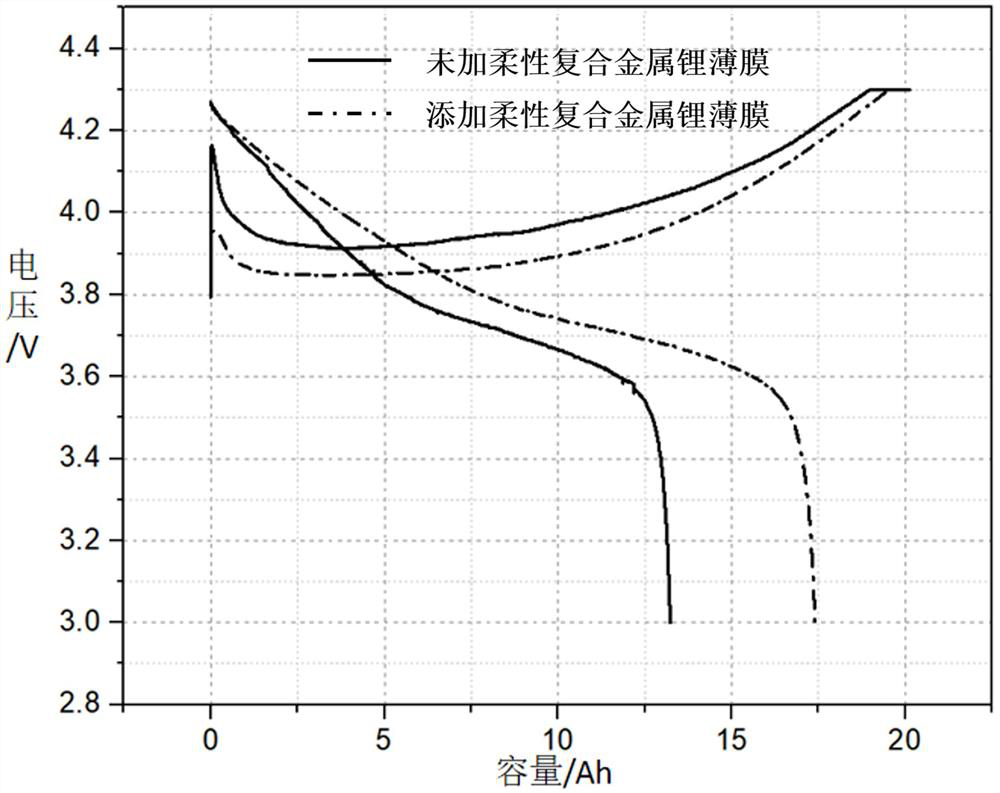

[0061] The flexible composite lithium metal f...

Embodiment 3

[0063] A flexible composite lithium metal film 4, comprising the following components:

[0064] Polyethylene terephthalate 9%

[0065] Superconducting carbon black 1%

[0066] Lithium particles 90%

[0067] Mix the above-mentioned substances according to the above ratio, pass in argon gas, and stir for 25 minutes through the stirring rod, wherein the stirring rod rotates at 3000rpm, heat to 250°C, and keep at this temperature for 2 hours to obtain a fluid mixture in a molten state. Pass the fluid mixture through Extruded by a twin-screw extruder, formed into a sheet film by a sheet head, and then rolled by a three-roller calender. The rolling pressure is 320kg, and the roll distance is 3μm. Finally, a flexible composite lithium metal film is obtained. 4 has a thickness of 4 μm, a tensile strength of 106 mPa, and an elongation at break of 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com