Catalyst impregnation device, catalyst impregnation method and application thereof

An impregnation device and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of uneven impregnation of catalysts, easy crushing of catalyst carriers, etc., to shorten the time required for impregnation, Protection is not easy to break, and the effect of accurately controlling the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

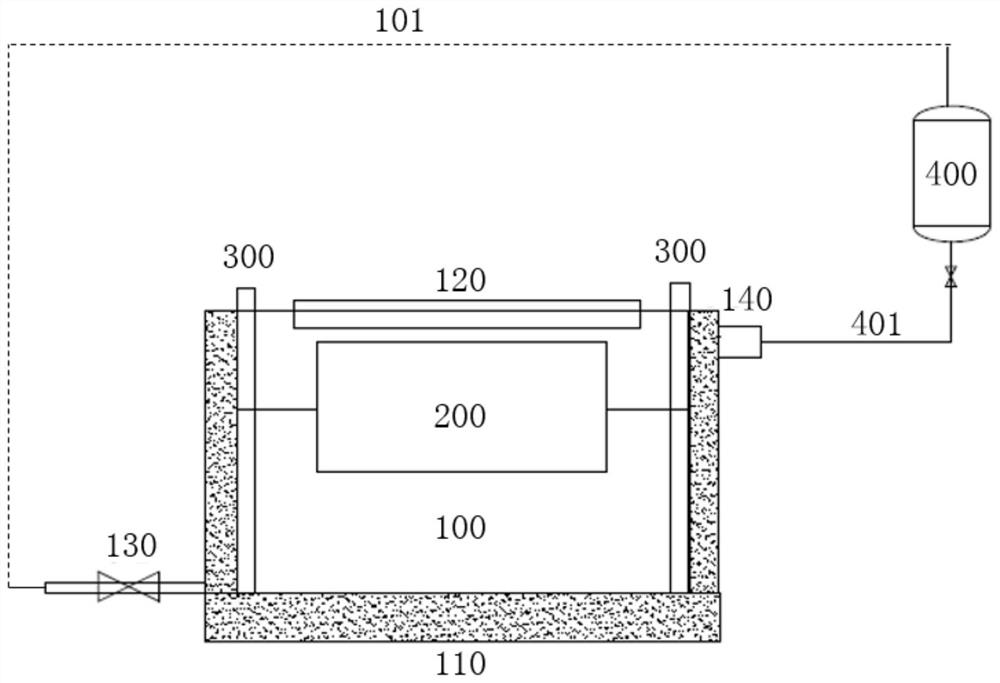

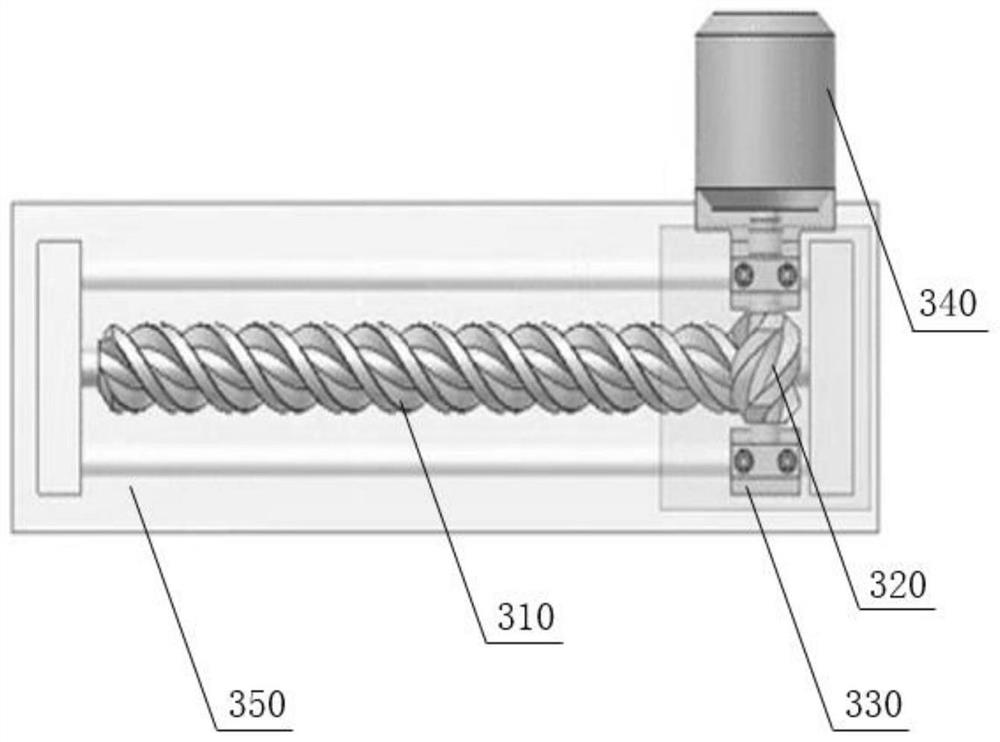

[0115] use figure 1 The device shown is performed as figure 1 As shown, the device includes an immersion unit 100, a carrier storage unit 200, a transmission unit 300, an immersion liquid preparation unit 400, a power unit, a reduction transmission unit and a control unit; the immersion unit 100 includes an immersion liquid tank 110, an immersion liquid tank cover 120, the discharge port 130 and the liquid inlet 140, are used to accommodate the immersion liquid and immerse; hole, the through hole is provided with a filter screen, the aperture of the filter screen is smaller than the size of the through hole, and the aperture of the through hole is smaller than the size of the carrier; the transmission unit 300 is connected to the impregnation unit 100 and The carrier storage unit 200 makes the carrier storage unit 200 reciprocate in the impregnation unit 100 along the direction perpendicular to the bottom surface of the impregnation unit 100, and makes the carrier storage uni...

Embodiment 2

[0122] Adopt the device of embodiment 1, carry out according to the method for embodiment 1, difference is:

[0123] In step 1), the amount of carrier added is 5 / 8 of the volume of the carrier box, the reciprocating motion rate of the carrier box in the vertical direction is adjusted to be 0.6m / min, and the rotational speed of the carrier box is 20RPM;

[0124] In step 2), the amount of the soaking liquid added is 3 / 5 of the volume of the soaking liquid 110 .

Embodiment 3

[0126] Adopt the device of embodiment 1, carry out according to the method for embodiment 1, difference is:

[0127] In step 1), the amount of carrier added is 3 / 4 of the volume of the carrier box, the reciprocating motion rate of the carrier box in the vertical direction is adjusted to be 0.8m / min, and the rotational speed of the carrier box is 30RPM;

[0128] In step 2), the amount of immersion liquid added is 4 / 5 of the volume of the immersion liquid 110 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com