Colored asphalt concrete with lasting color and production method thereof

A technology of colored asphalt and decolorized asphalt, applied in the field of concrete, can solve the problems of poor color persistence of colored asphalt concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0037] A color stabilizer, which is prepared by the following method:

[0038] According to the dosage in Table 1, mix molasses and ammonium nitrate, stir evenly, add dipropylene polyurethane protective agent and maltodextrin and mix to obtain a color stabilizer.

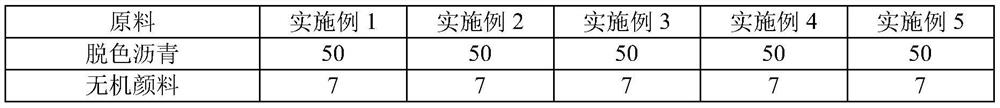

preparation example 2-5

[0040] The preparation method and raw material types of the color stabilizer of Preparation Example 2-5 are exactly the same as those of Preparation Example 1, the difference is that the dosage of each raw material is different, as shown in Table 1 for details.

[0041]Each raw material dosage (unit: kg) of the color stabilizer of table 1 preparation example 1-5

[0042] raw material Preparation Example 1 Preparation example 2 Preparation example 3 Preparation Example 4 Preparation Example 5 Dipropylene polyurethane protective agent 5 10 15 10 10 Maltodextrin 2 2 2 2 2 molasses 9 9 9 8 10 ammonium nitrate 5 5 5 5 5

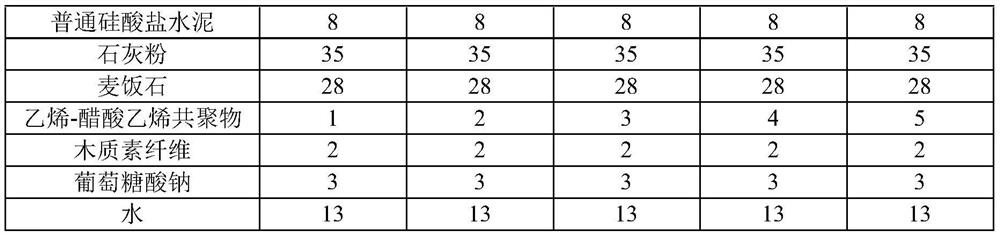

Embodiment 1

[0044] The colored asphalt concrete of embodiment 1 obtains by following operation steps:

[0045] According to the dosage in Table 2, add decolorized asphalt, inorganic pigments, lime powder, medical stone, ethylene-vinyl acetate copolymer, lignin fiber and sodium gluconate into water and mix, and stir evenly at 160°C to obtain a mixture Material A;

[0046] Add ordinary Portland cement and other raw materials into the mixture A, and stir evenly to obtain colored asphalt concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com