Low-viscosity organic phosphonic acid polymer filtrate reducer as well as preparation method and application thereof

A technology of organic phosphonic acid and fluid loss reducer, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of unfavorable on-site application, etc., and achieve the benefits of on-site application, good calcium and magnesium resistance, and reduced viscosity effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a method for preparing a low-viscosity organic phosphonic acid polymer fluid loss control agent, comprising the following steps:

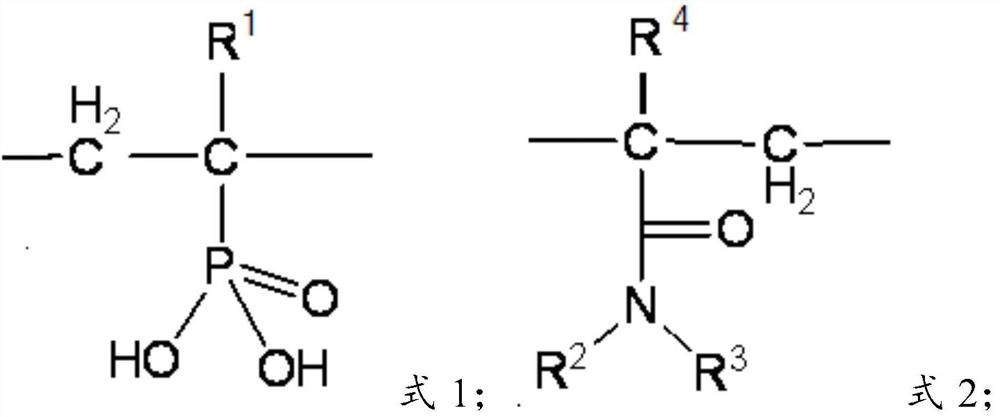

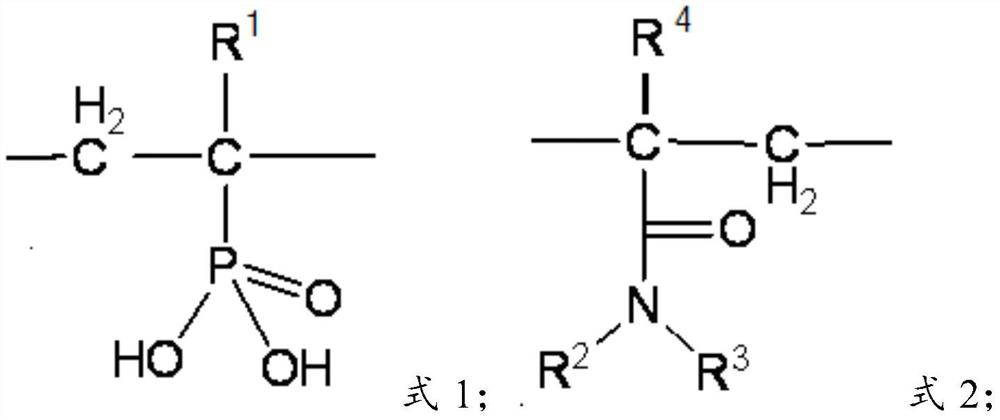

[0045] The acrylic phosphonic acid monomer and the acrylamide monomer are polymerized to obtain a low-viscosity organic phosphonic acid polymer fluid loss reducer; the low-viscosity organic phosphonic acid polymer fluid loss reducer has a formula 1 The first repeating unit and the second repeating unit of the structure of formula 2:

[0046]

[0047] Among them, R 1 , R 2 , R 3 and R 4 independently selected from hydrogen, methyl or ethyl; the molar ratio of the first repeating unit to the second repeating unit is (0.03-0.3): (0.7-0.97);

[0048] The relative molecular weight of the low-viscosity organic phosphonic acid polymer fluid loss reducer is 350,000-600,000.

[0049] There are many types of raw materials used in the synthesis of some low-viscosity polymer fluid loss control agents, and the synthesis pro...

Embodiment 1

[0062] Mix isopropenylphosphonic acid and acrylamide according to the mass ratio of 30%:70% to form a monomer mixture aqueous solution with a mass fraction of 30%, and adjust the pH value to 8 with an appropriate amount of lye. And, 0.3% potassium persulfate accounting for the total mass of the monomers was formulated into a 2.0% initiator aqueous solution.

[0063] Add the aqueous solution of the monomer mixture into the reaction vessel, seal it with nitrogen for 30 minutes, remove the oxygen, and raise the temperature to 60°C; under the protection of nitrogen, add the aqueous solution of the initiator into the reaction vessel, stir evenly, and wait for the system After starting to heat up, the reaction was carried out for 3 hours. After the reaction, the obtained product is granulated, dried and crushed to obtain the phosphine-containing drilling fluid fluid loss reducer as white powder.

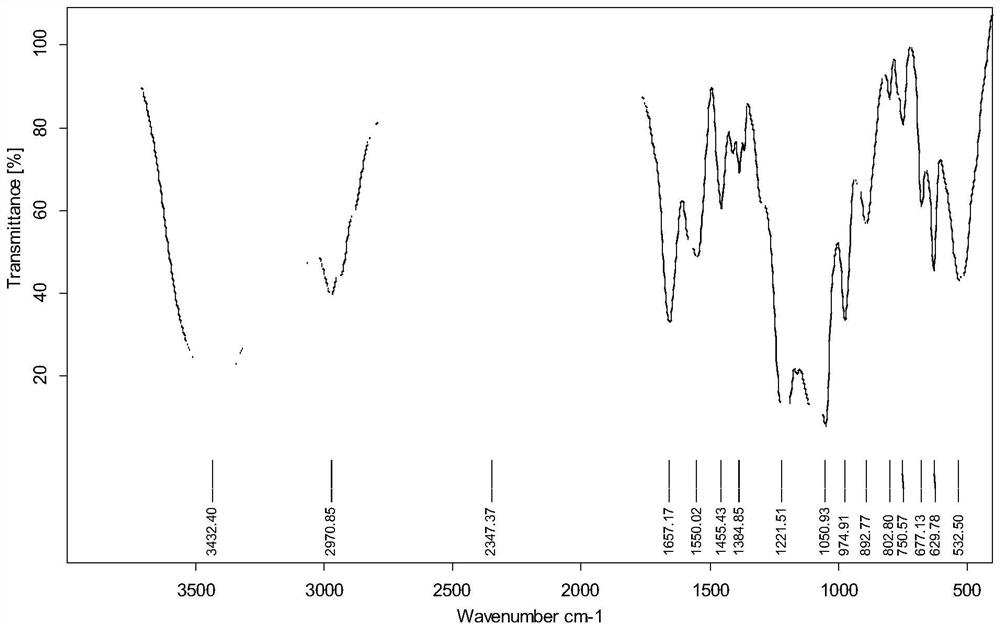

[0064] The resulting product was characterized by infrared, and the results were as f...

Embodiment 2~7

[0066] According to the method of Example 1, organic phosphonic acid polymer fluid loss reducers were prepared respectively; different formulations and conditions are shown in Table 1:

[0067] The substance consumption and reaction condition of polymerization reaction in the embodiment 2~7 of table 1

[0068]

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com