Intrinsic high-flexibility and high-thermal-conductivity liquid crystal elastomer material as well as preparation and application thereof

A liquid crystal elastomer and high flexibility technology, applied in the field of high thermal conductivity liquid crystal elastomer materials and intrinsically high flexibility, can solve the problems of poor flexibility, complex preparation of thermally conductive liquid crystal polymer thermal interface materials, and unfavorable large-scale production. Complex preparation, improved phonon scattering free path, and improved tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

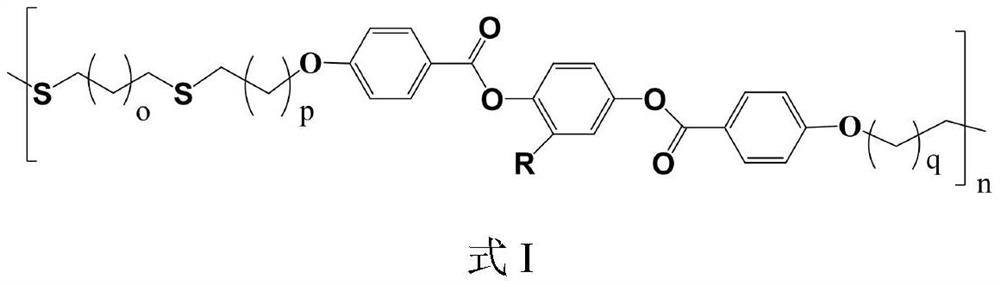

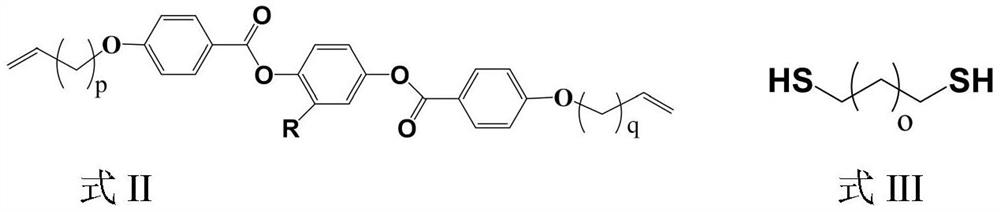

Method used

Image

Examples

Embodiment 1

[0047]Dissolve 5.29g (10mmol) of double-terminal double-bond liquid crystal monomer, 0.97g (9mmol) of chain extender, and 0.026g (0.01mmol) of photoinitiator in 10mL of dichloromethane, and irradiate with 365nm ultraviolet light for 2 minutes after complete dissolution , stirred at room temperature for 1 hour, then added 0.244g (0.5mmol) cross-linking agent, 0.026g (0.01mmol) photoinitiator, evaporated dichloromethane after thorough mixing, vacuum dried for 1 day, and placed the mixture on a centrifugal membrane for heating After 120°C, the temperature was lowered to 100°C to form an ordered liquid crystal phase, placed on a calender at 100°C, uniaxially stretched and oriented, and crosslinked with 365nm ultraviolet light for 2 minutes, and the film was taken out to obtain an oriented liquid crystal elastomer. The thermal conductivity in the orientation direction of the film is 1.2 W / m·K, the longitudinal thermal conductivity is 0.5 W / m·K, and the elongation at break is 600%. ...

Embodiment 2

[0049] Dissolve 2.22g (5mmol) of double-terminal double-bond liquid crystal monomer, 1.52g (4mmol) of chain extender, and 0.026g (0.01mmol) of photoinitiator in 10mL of dichloromethane. , stirred at room temperature for 1 hour, then added 0.244g (0.5mmol) cross-linking agent, 0.026g (0.01mmol) photoinitiator, evaporated dichloromethane after thorough mixing, vacuum dried for 1 day, and placed the mixture on a centrifugal membrane for heating After 120°C, the temperature was lowered to 100°C to form an ordered liquid crystal phase, placed on a calender at 100°C, uniaxially stretched and oriented, and crosslinked with 365nm ultraviolet light for 2 minutes, and the film was taken out to obtain an oriented liquid crystal elastomer. The thermal conductivity in the orientation direction of the film is 1.0 W / m·K, the longitudinal thermal conductivity is 0.4 W / m·K, and the elongation at break is 500%.

Embodiment 3

[0051] Dissolve 5.29g (10mmol) double-terminal double-bond liquid crystal monomer, 0.244g (0.5mmol) cross-linking agent, 0.026g (0.01mmol) photoinitiator in 10mL dichloromethane, and evaporate the dichloromethane after fully mixing , vacuum-dry for 1 day, place the mixture on a centrifugal membrane and heat it at 120°C, then cool down to 100°C to form an ordered liquid crystal phase, put it on a calender at 100°C, and cross-link with 365nm ultraviolet light for 2 minutes after uniaxial stretching and orientation, take out The thin film obtains the alignment liquid crystal elastomer. The thermal conductivity in the orientation direction of the film is 0.8 W / m·K, the longitudinal thermal conductivity is 0.3 W / m·K, and the elongation at break is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com