Process method for regenerating asphalt activating agent by utilizing refined slurry oil

A technology of recycled asphalt and process method, which is applied in the petroleum industry, processing hydrocarbon oil, refining and cracking process treatment of multi-stage series connection, etc. The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

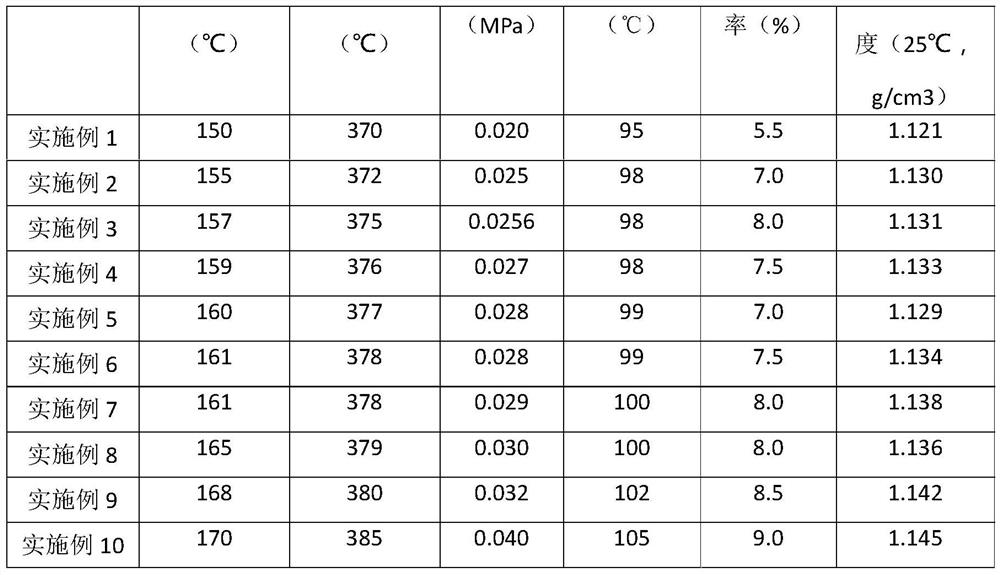

Embodiment 1~10

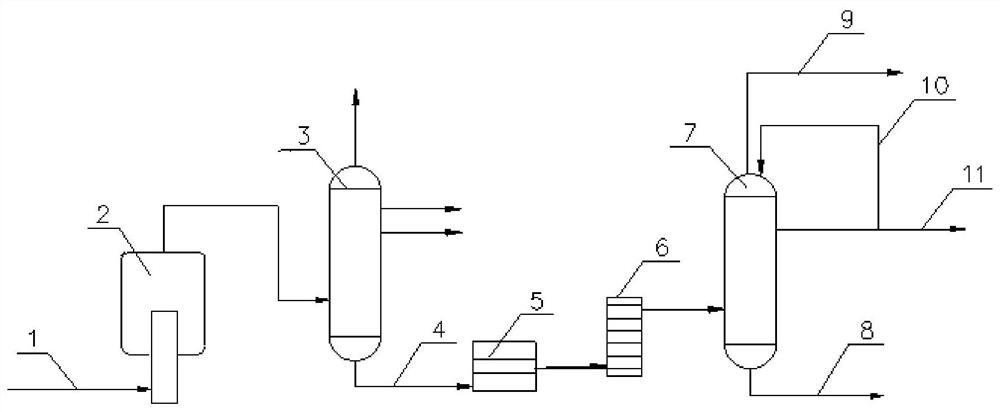

[0028] Such as figure 1 Shown, the present invention utilizes refining oil slurry to regenerate the technological process of asphalt activator.

[0029] 1) The raw material of FCC is the hydrogenated residual oil produced by the upstream residual oil hydrogenation unit. Adjust the feed composition of the FCC process. It is not allowed to blend hydrogenated tail oil and unhydrogenated residual oil, that is, the feed is 100% hydrogenated The residual oil is subjected to a catalytic reaction at a reaction temperature of 510°C and a reaction pressure of 0.25 MPa. The reaction oil gas enters the FCC fractionation tower, and the temperature control of the sensitive plate of the FCC fractionation tower is detailed in Table 1;

[0030] 2) The bottom product of the FCC fractionation tower is sent to a membrane filter, and the filtration accuracy is controlled at 5 μm, and a flexible membrane filter is sufficient;

[0031] 3) Pass the filtered material into a heating furnace for heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com