Fixture tool, assembling table, substrate assembly and assembling method and fixing method of substrate assembly

An assembly table and fixture technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of scratches and low self-weight in the contact part between the tooling and the substrate surface, so as to reduce the scrap rate and reduce the Assembly difficulty and the effect of improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

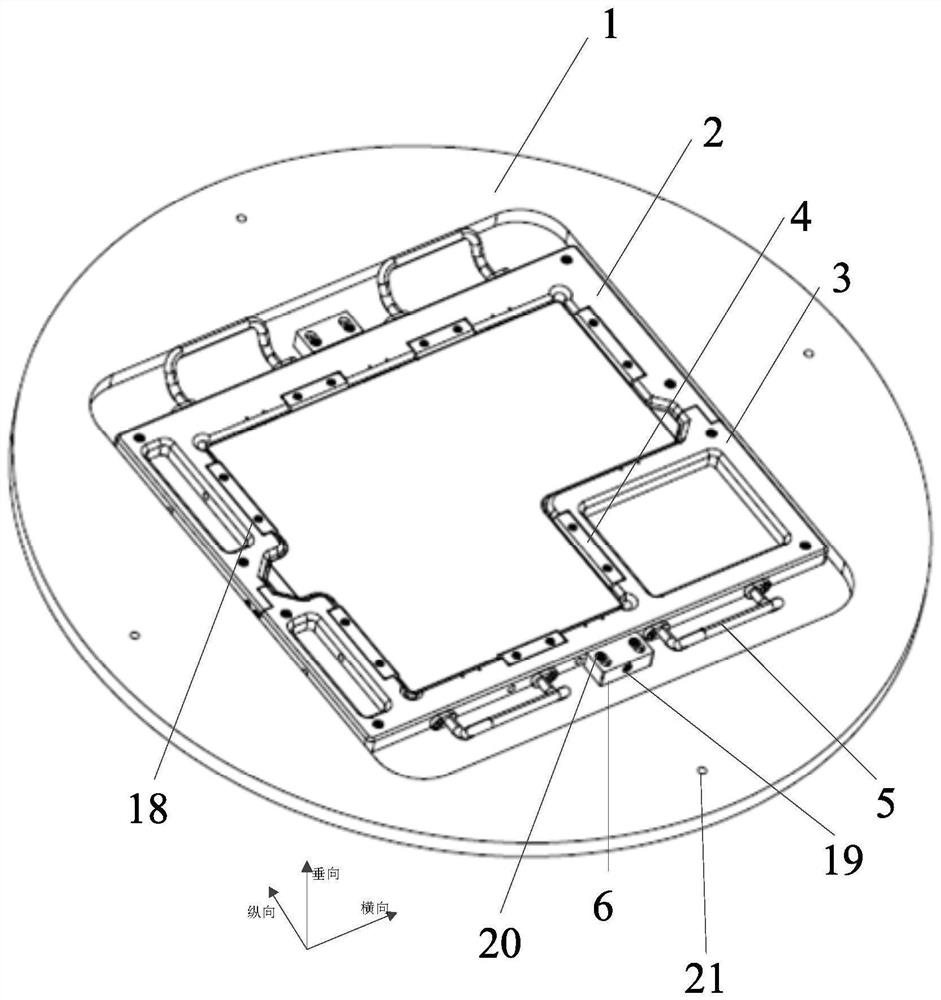

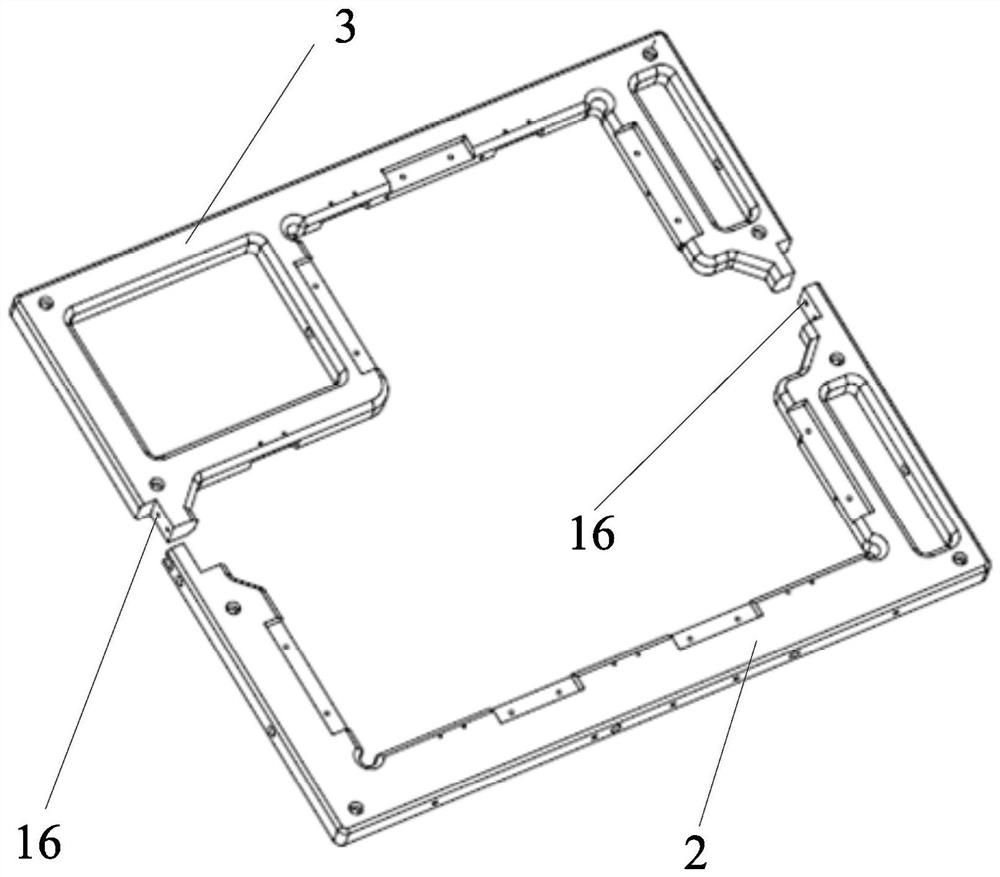

[0111] Such as figure 2 with image 3 As shown, this embodiment provides a jig tool, which includes a jig frame part 2, a jig frame two part 3 and a wedge 7, a jig frame part 2 and a jig frame two part 3 The main body of the fixture frame can be formed through assembly; the wedge 7 is detachably connected with the first part 2 of the fixture frame and the second part 3 of the fixture frame; the first part 2 of the fixture frame and the second part 3 of the fixture frame are used for The two sides opposite to the substrate 10 are attached; the main body of the fixture frame is arranged around the substrate 10; the wedge 7 is used to extend into the side wall groove of the substrate 10 during the assembly process, wherein the mating end surface 25 of the wedge is in contact with the substrate There is a gap between the mating end surfaces of the side wall groove of 10 .

[0112] The frocks in the prior art include crimp-type frocks and shrapnel-type frocks. The crimping tool...

Embodiment 2

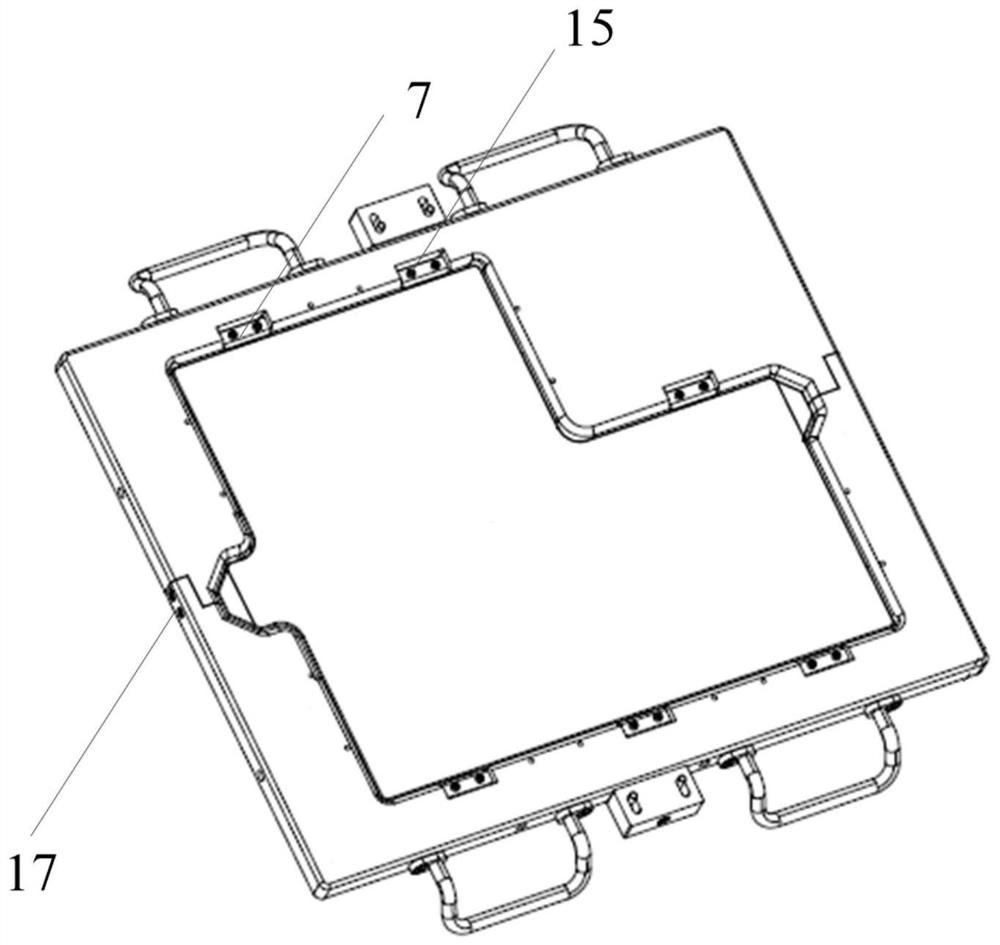

[0122] On the basis of Example 1, as image 3 As shown, the fixture tooling also includes a wedge screw 15, and the wedge 7 is fixed on the first part 2 of the fixture frame or the second part 3 of the fixture frame through the wedge screw 15, which is beneficial to realize that the wedge 7 and the first part of the fixture frame 2 or the detachable connection of fixture frame two 3.

[0123] When the substrate 10 is made of a microcrystalline material, the wedge 7 is made of a polytetrafluoroethylene material; or, when the substrate 10 is made of a quartz material, the wedge 7 is made of an aluminum alloy material, which is conducive to better Protect the substrate 10 .

[0124] The fixture tooling also includes assembly screws 17, the fixture frame part 2 and the fixture frame two parts 3 are provided with assembly holes 16, and the assembly screws 17 can be inserted into the assembly holes 16 on the fixture frame part 2 and the fixture frame The assembly hole 16 on the se...

Embodiment 3

[0129] Such as Figure 7 with Figure 8 As shown, this embodiment also provides an assembly platform 8 for assembling the above-mentioned substrate assembly, the assembly platform 8 includes a support body, the top surface of the support body is provided with a support seat 9, and the end of the support seat 9 forms a limited position. Line 12, used for aligning with the edge line of substrate 10; Guide groove 11 is provided with along two longitudinal sides on the top surface of support main body, the longitudinal side of fixture frame one 2 and fixture frame two parts 3 can be positioned at Sliding in the guide groove 11, there is a gap between the groove wall of the guide groove 11 and the side walls of the longitudinal sides of the fixture frame part 2 and the fixture frame part 3.

[0130] The assembly table 8 can assist in assembling the substrate components, reduce assembly difficulty, and improve assembly accuracy.

[0131] The effect of the limit line 12 is conduciv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com