Method for detecting leakproofness of side suction port of trailing suction ship

A detection method and sealing technology are applied in the field of detection of the airtightness of the suction port on the side of a raking suction ship, which can solve the problems such as the decline of the production efficiency of the mud raking suction ship, leakage at the suction port on the side, and the flow rate of water body pollution into the tank, and the detection conditions are met. Ease of satisfaction, easy to calculate and obtain, accurate detection method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

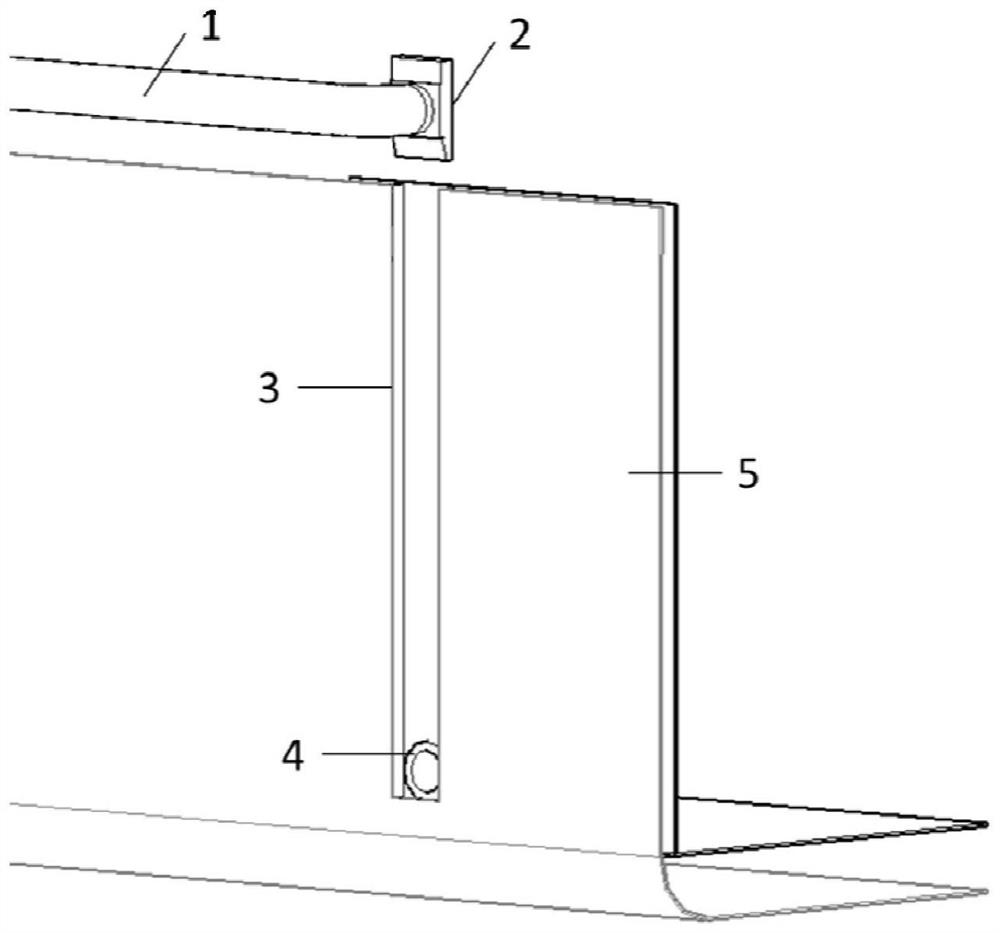

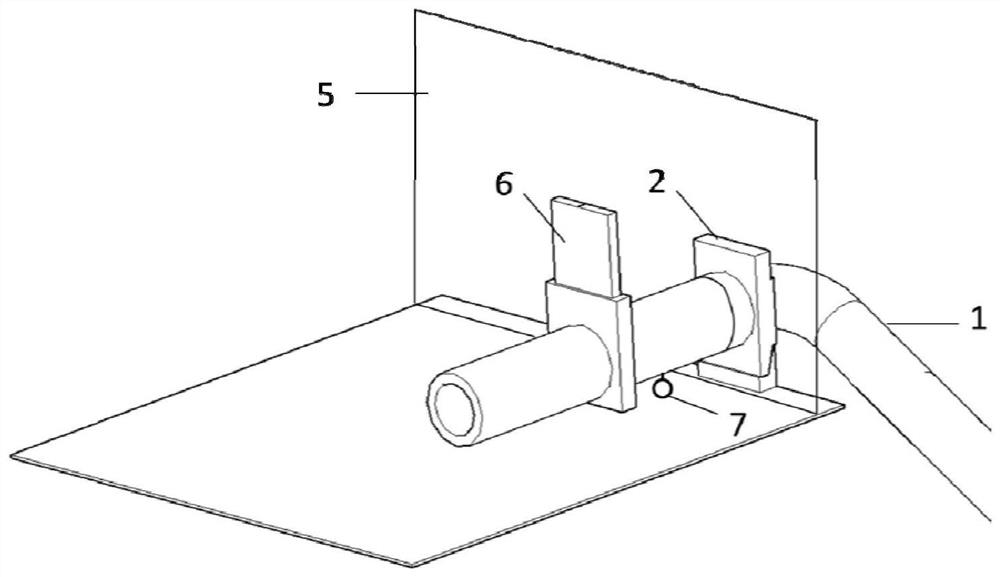

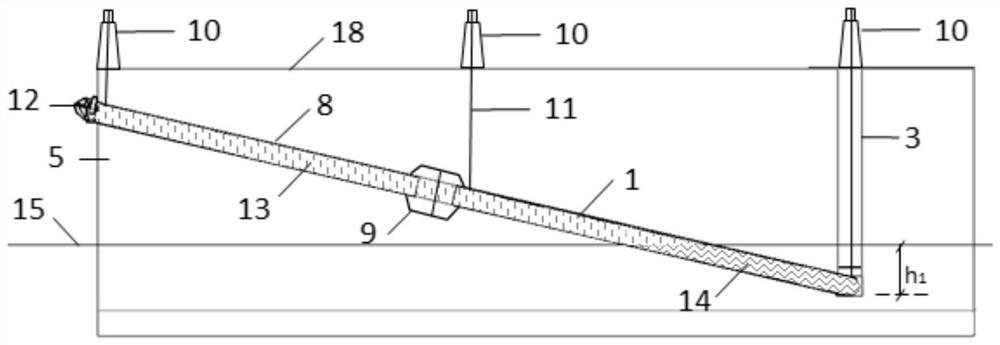

[0051] A specific implementation case is listed below to set forth the specific implementation process of the present invention:

[0052] A suction ship with a cabin capacity of 18,000 square meters has a light load draft of 5.5m and a heavy load draft of 11m. The diameter of the rake pipe is 1.2m and the length of the pipe is 45m. Double rakes are installed on both sides, and a rake arm pump is installed in the middle of the left rake pipe. The pump sucks the mud and loads the tank, the right harrow has no rake arm pump, and the pump in the tank is used to suck the mud and load the tank. During the construction process, check the tightness of the side suction ports 4 on both sides, and set the critical value of the positive pressure relief rate to 0.02m·H 2 O / s, negative pressure release rate critical value 0.01m·H 2 O / s. The operation process is as follows:

[0053] (1) Leakage detection of port side suction port 4

[0054] Lift the left rake pipe to the deck surface 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com