Tubular ozone advanced oxidation catalyst

An advanced oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, oxidized water/sewage treatment, etc., can solve the problem of low dispersion and avoid low porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

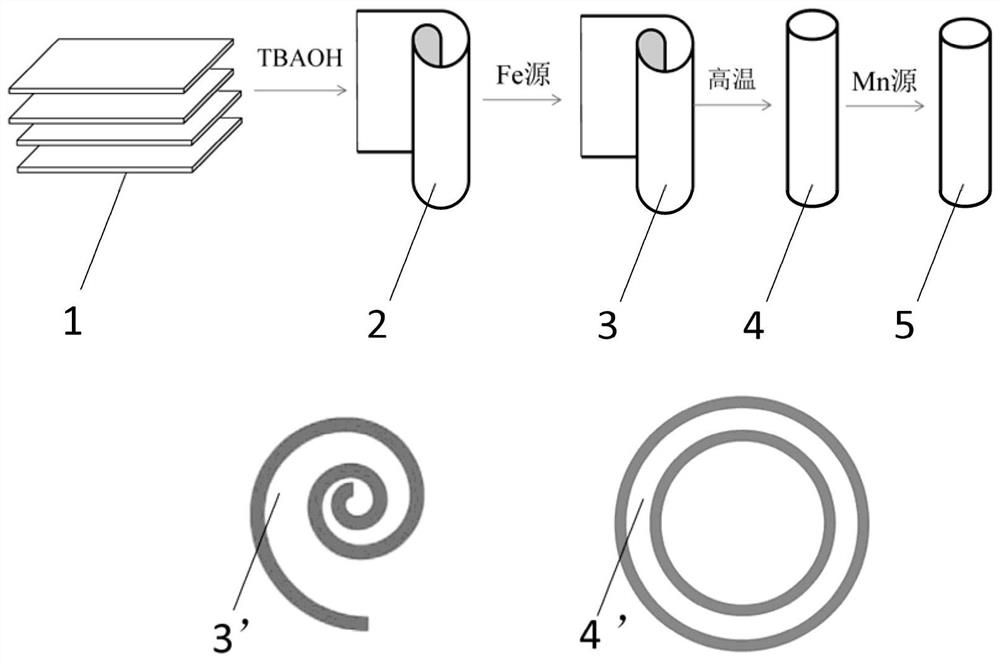

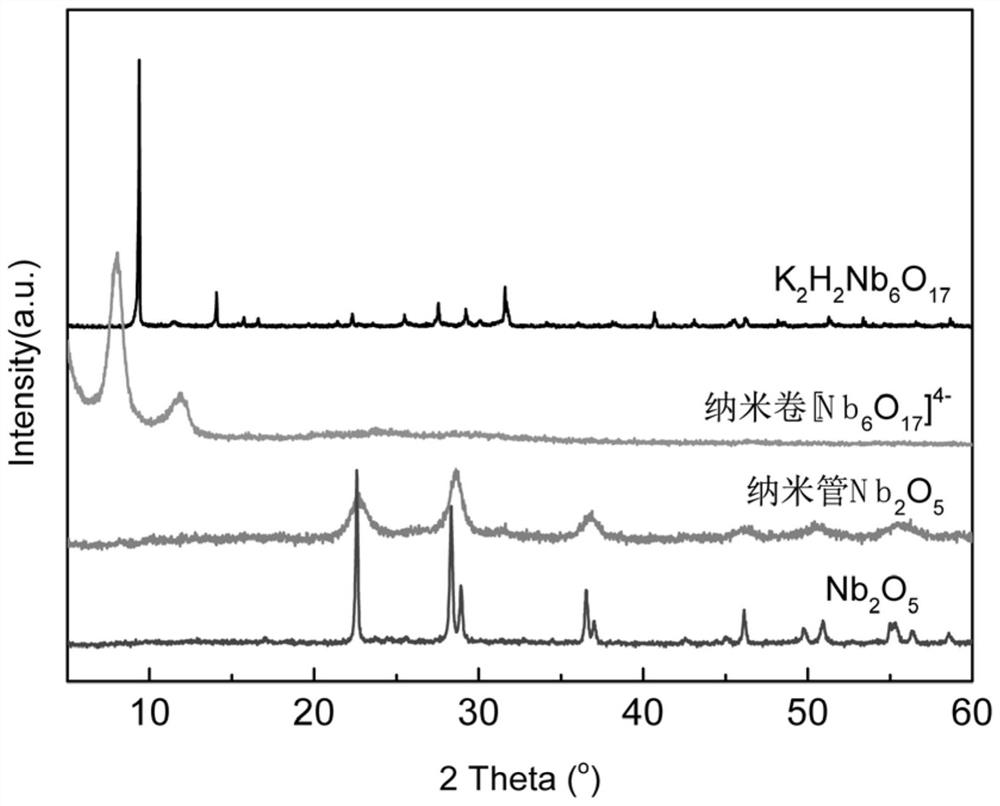

[0024] Take 10g layered material K 2 h 2 Nb 6 o 17 , dispersed in 1L deionized water, stirred in an ice-water mixing bath, added tetrabutylammonium hydroxide (TBAOH), adjusted the pH value to 10, stirred for 3 days, and centrifuged at 10000rpm to obtain the upper layer suspension. Take 1ml of the upper layer suspension and dry at 105°C for 24h to obtain [Nb 6 o 17 ] 4- Nano volume thickness ≤ 2nm, nano volume length 200-500nm, nano volume [Nb 6 o 17 ] 4- Concentration 2mg / mL.

[0025] Take the above 2mg / mL nanovolume [Nb 6 o 17 ] 4- Suspension 500mL, add 0.1mol / L ferric nitrate solution dropwise to flocculate all the nanovolumes, continue stirring for 4h, centrifuge at 10000rpm, dry the obtained solid under vacuum at 80°C for 12h, calcining at 525°C, and calcining for 3h, to obtain Tubular Fe / Nb 2 o 5 .

[0026] Take 1g of tubular Fe / Nb 2 o 5 , add 100ml of deionized water to disperse, add 0.054g of manganese nitrate, stir and dissolve fully, dry by rotary eva...

Embodiment 2

[0028] Take 10g layered material K 2 h 2 Nb 6 o 17 , dispersed in 1L deionized water, stirred in an ice-water mixing bath, added tetrabutylammonium hydroxide (TBAOH), adjusted the pH value to 10, stirred for 7 days, and centrifuged at 9000rpm to obtain the upper suspension. Take 1ml of the upper layer suspension and dry at 105°C for 24h to obtain [Nb 6 o 17 ] 4- Nano volume thickness ≤ 2nm, nano volume length 200-500nm, nano volume [Nb 6 o 17 ] 4- Concentration 4mg / mL.

[0029] Take the above 4mg / mL nanovolume [Nb 6 o 17 ] 4- Suspension 500mL, 0.1mol / L ferric chloride solution was added dropwise to flocculate all the nanovolumes, stirring time was 4h, centrifugation speed was 9000rpm, the obtained solid was vacuum-dried at 80°C for 12h, calcining temperature was 525°C, calcining time was 3h, and obtained Tubular Fe / Nb 2 o 5 .

[0030] Take 1g of tubular Fe / Nb 2 o 5 , add 100ml of deionized water to disperse, add 0.18g of manganese nitrate, stir and dissolve fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com