Preparation method of high-temperature-resisting battery diaphragm

A battery separator and high temperature resistance technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of easy generation of closed pores and inability to store lithium ions in electrolyte, and achieve high temperature resistance performance and air permeability. The effect of good air permeability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

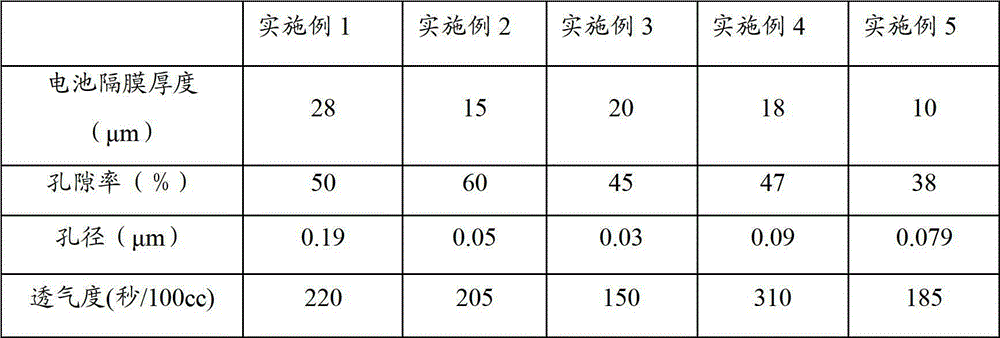

Examples

Embodiment 1

[0026] First, dissolve 4,4'-diaminodiphenyl ether and pyromellitic dianhydride in the organic solvent N,N'-dimethylacetamide to obtain a polyimide precursor solution; where 4,4' - The molar ratio of diaminodiphenyl ether and pyromellitic dianhydride is 1:1, and the weight of solvent N,N'-dimethylacetamide is 4,4'-diaminodiphenyl ether and pyromellitic acid 12 times the total weight of dianhydride; the temperature of the solution is controlled at 10-30°C during the preparation process.

[0027] Then, use a film applicator to coat the polyimide precursor solution prepared in the above steps on a clean and dry glass substrate with a coating thickness of 300 μm, soak in acetone / water (1:1 volume ratio) for 0.5 minutes, then soak in water for 0.5 minutes.

[0028] Finally, leave the prepared film for 2 minutes, stretch the non-woven fabric with a steel sheet, put it into an oven to heat, first keep it at 90°C for 30 minutes, then raise the temperature to 250°C for 30 minutes, and ...

Embodiment 2

[0030] First, dissolve 4,4'-diaminobiphenyl and 3,3',4,4'-biphenyltetracarboxylic dianhydride in organic solvent N,N'-dimethylacetamide to obtain polyimide Amine precursor solution; the molar ratio of 4,4'-diaminobiphenyl and 3,3',4,4'-biphenyltetracarboxylic dianhydride is 1:1.01, solvent N,N'-dimethyl The weight of acetamide is 15 times of the total weight of 4,4'-diaminobiphenyl and 3,3',4,4'-biphenyltetracarboxylic dianhydride; the temperature of the solution is controlled at 10-30°C during the preparation process .

[0031] Then, use a film applicator to coat the polyimide precursor solution prepared in the above steps on a clean and dry glass plate substrate with a coating thickness of 150 μm, soak in acetone / water (2:1 volume ratio) for 0.8 minutes, followed by soaking in ethanol / water (1:2 volume ratio) for 0.5 minutes.

[0032] Finally, place the prepared film for 4 minutes, put it into an oven to heat, first keep it at 80°C for 60 minutes, then raise the temperatur...

Embodiment 3

[0034] First, dissolve 1,2',3,3'-benzophenone tetracarboxylic dianhydride and 3,3'-dimethyl-4,4'-diaminobenzophenone in organic solvent N,N '-Dimethylacetamide to obtain a polyimide precursor solution; wherein 1,2',3,3'-benzophenone tetracarboxylic dianhydride and 3,3'-dimethyl-4, The molar ratio of 4'-diaminobenzophenone is 1:0.99, the weight of solvent N,N'-dimethylacetamide is 1,2',3,3'-benzophenone tetracarboxylic dianhydride and 10 times the total weight of 3,3'-dimethyl-4,4'-diaminobenzophenone; during the preparation process, the temperature of the solution is controlled at 10-30°C.

[0035]Then, use a film applicator to coat the polyimide precursor solution prepared in the above steps on a clean and dry glass substrate with a coating thickness of 210 μm and soak it in acetone / water (3:1 volume ratio) for 0.8 minutes, then soak in water for 0.5 minutes.

[0036] Finally, place the prepared film for 4 minutes, put it into an oven to heat, first keep it at 90°C for 60 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com