Simple robot stacking control system and method

A control system and robot technology, applied in the field of robot palletizing, can solve the problems of high operator ability requirements, single function of palletizing process package, and inability to meet actual production, etc., achieve low technical requirements, improve intelligence, and be easy to use The effect of calling and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

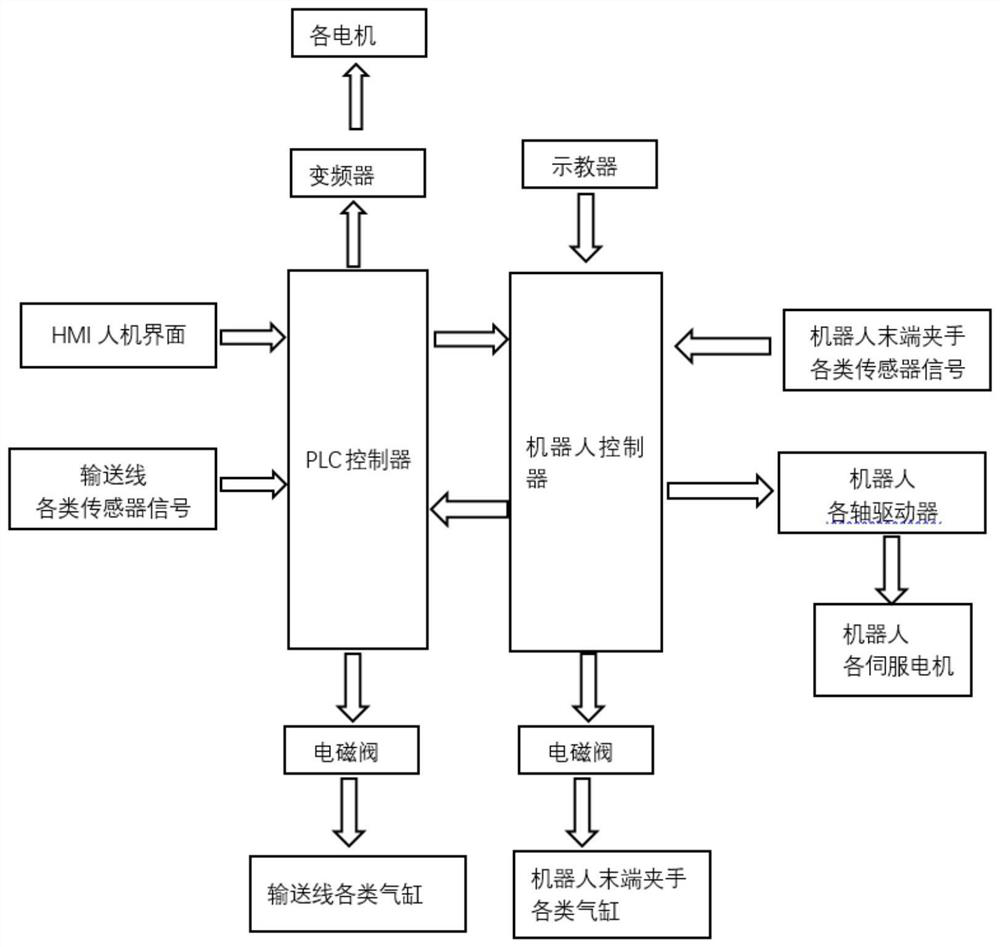

[0037] refer to figure 1 , this embodiment discloses a simple robot palletizing control system, including: HMI human-machine interface, PLC controller, robot controller, and sensor components;

[0038]The HMI man-machine interface is configured to connect and interact with the PLC controller, and the PLC controller is used to receive and process parameters of the HMI man-machine interface, so that the HMI man-machine interface and the PLC controller perform human-computer interaction ;

[0039] The robot controller is configured to communicate with the PLC controller, so that the PLC controller and the robot controller perform information interaction, and the PLC controller writes the palletizing formula data of the HMI man-machine interface into the robot control and receive information feedback from the robot controller, so that the robot controller can issue instructions to control the actions of the robot, and generate motion trajectories to complete the palletizing task ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com