Micro-groove jet polishing device and polishing method

A polishing device and micro-groove technology, which is applied to used abrasive processing devices, abrasive jet machine tools, abrasives, etc., can solve the problems of limiting the application of micro-groove structures, high processing efficiency, and complex equipment costs, etc., to achieve easy Automated processing, low production cost, and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

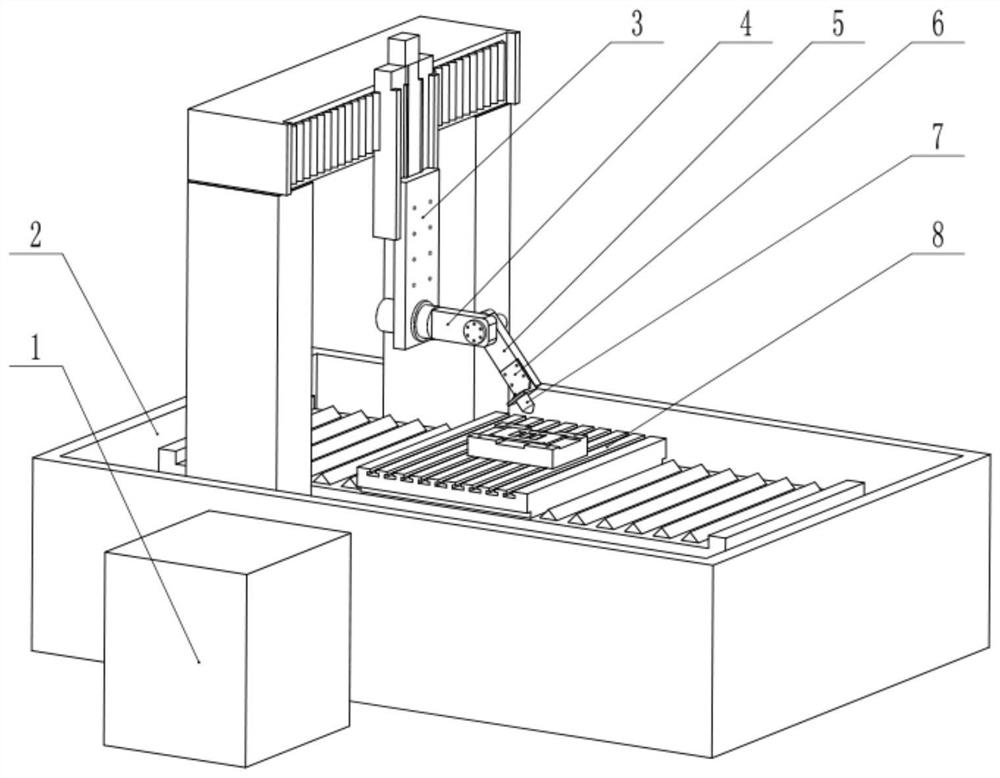

[0046] like figure 1 As shown, a micro-groove jet polishing device includes a base 2, a liquid supply system 1, a polishing nozzle 7 and a worktable 8, and a side wall of the base 2 is provided with the liquid supply system 1. The liquid supply system 1 is used to deliver the polishing liquid containing abrasive particles to the polishing nozzle so as to impact the micro-grooves to be polished. Wherein, the abrasive particles in the polishing liquid interact with the workpiece for nano-removal, so as to realize polishing micro-grooves; the liquid supply system 1 transports the configured polishing liquid to the Polishing nozzle 7. A five-axis motion platform is fixedly installed on the base 2 for adjusting the posture of the polishing nozzle relative to the workpiece to be processed, including a three-axis linear motion mechanism and a two-axis rotary motion mechanism. The polishing nozzle 7 is installed at the end of the five-axis motion platform. The three-axis linear mot...

Embodiment 2

[0057] This embodiment is basically the same as Embodiment 1, except that the cover plate 11 is replaced with the mask 12 . like figure 1 , Figure 5 As shown in -7, the micro-groove jet polishing device of the present invention includes a base 2, a liquid supply system 1, a polishing nozzle 7 and a worktable 8, and a mask 12 for polishing the micro-groove.

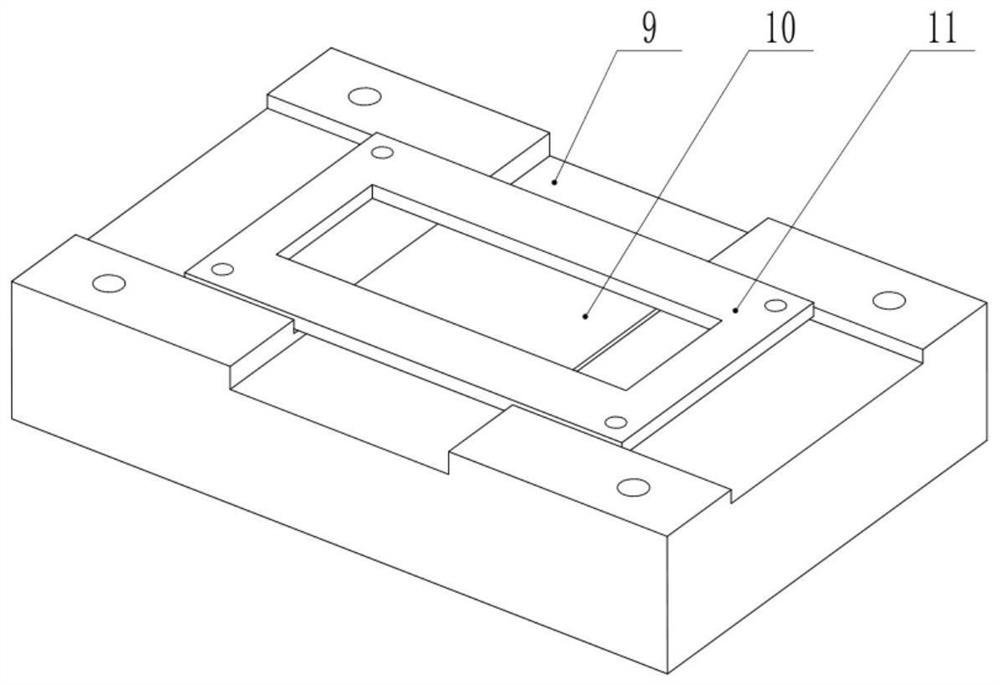

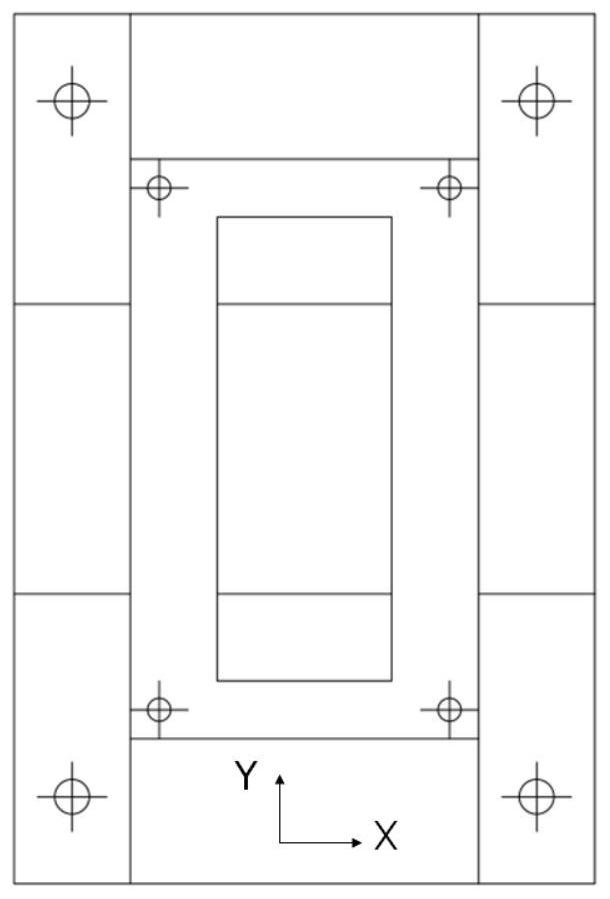

[0058] Figure 5 -7 shows a schematic diagram of the mask 12 fixing the workpiece, and its ends are correspondingly provided with holes for riveting with the object table 9 , the mask 12 is pressed on the workpiece, and then riveted with the object table 9 . The mask 12 has grooves, and the width of the bottom of the grooves of the mask is the same as the width of the micro-grooves to be polished. As shown in FIG. 7 , the groove sidewall of the mask has an inclination angle of 45°, and the sidewall of the mask groove can control the polishing liquid jet ejected by the polishing nozzle 4 along the mask groove on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com