Purification method of natural graphite

A purification method and natural graphite technology, applied in the field of natural graphite purification, can solve the problems of product purity to be improved, difficulty in mass production, waste of resources, etc., and achieve the effects of complete dissolution of impurities, reduction of pollution, and reduction of raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

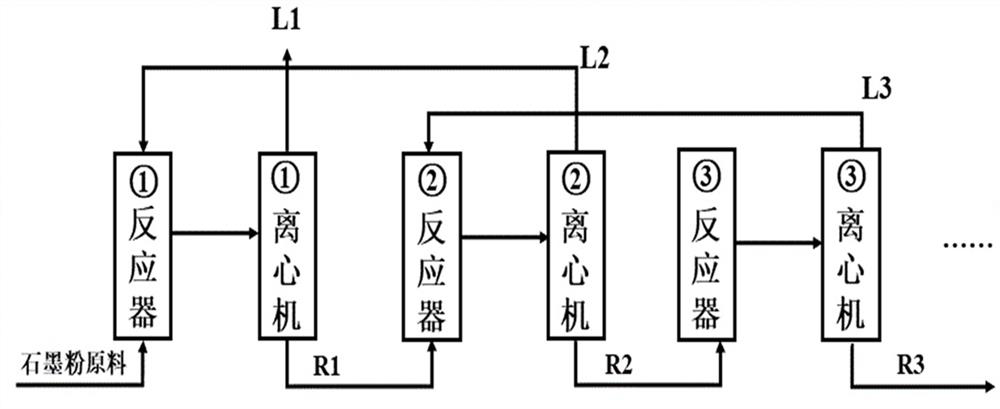

[0020] Embodiment 1: a kind of operation graphite purification method that adopts multistage countercurrent reaction, concrete technical scheme is as follows:

[0021] Select Lutang graphite powder raw material in Chenzhou City, Hunan Province, with a carbon content of 74.8%;

[0022] 1) Add the graphite powder raw material from the first-stage reaction kettle, add the centrifuged liquid separated from the second stage according to the liquid-solid volume ratio of 2:1, and stir for 2.0 hours under normal pressure and temperature of 70°C to obtain acid leaching Graphite; the liquid after centrifugation of acid-leached graphite is waste liquid, which enters the waste liquid recovery unit;

[0023] 2) Put the solid matter after the first-stage centrifugation into the second-stage reaction kettle to remove impurities; add the centrifuged liquid separated from the third stage according to the liquid-solid volume ratio of 2:1, and stir under normal pressure and temperature at 70°C ...

Embodiment 2

[0025] Embodiment 2: Compared with Embodiment 1, the reaction order is 4, and other conditions are all the same.

Embodiment 3

[0026] Embodiment 3: Compared with Embodiment 1, the mass concentration of hydrofluoric acid added in the fresh acid is 20%, and other conditions are all the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com