A kind of off+eri structure msect-4 molecular sieve, its preparation method and application

A technology of molecular sieves and structure directing agents, which is applied in the direction of molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve the problems of long synthesis period, expensive molecular sieve body and poor low temperature performance of traditional methods, and achieve excellent water quality. Effects of thermal stability, short synthesis time, and high nitrogen selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

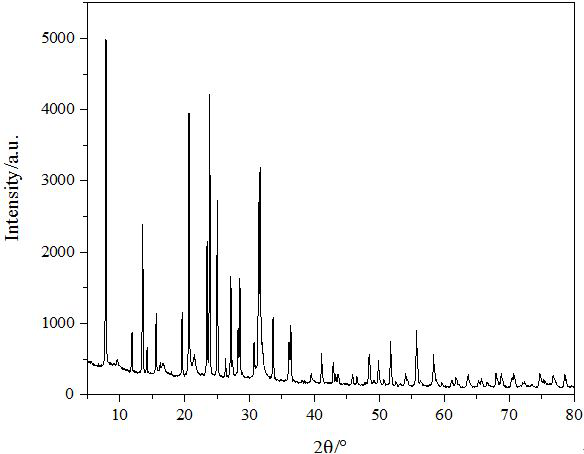

[0059] Weigh 3.28g NaAlO respectively 2 and 2 g of KOH were dissolved in 20 g of water, stirred for 1 h until the solution was clear, added 20 g of N,N,N-trimethyladamantanium, and continued to stir for 2 h until the solution was uniformly mixed, and the pH of the solution was greater than 11.9. Subsequently, 60 g of silica sol was added and stirring was continued for 4 hours to form a uniform sol-gel. Continue to age for 10h and then 160 ℃ constant temperature crystallization for 8h. Then it was dried and calcined at a calcination temperature of 550 °C and a constant temperature of 3 h; the prepared molecular sieve was labeled as K-msect-4. Configure 0.5M NH 4 NO 3 solution, 5 g of K-msect-4 molecular sieve was mixed with 500 ml of this solution and stirred for 12 h, repeated three times, dried and calcined at a calcination temperature of 550 °C and a constant temperature of 3 h; the prepared molecular sieve was labeled as H-msect-4.

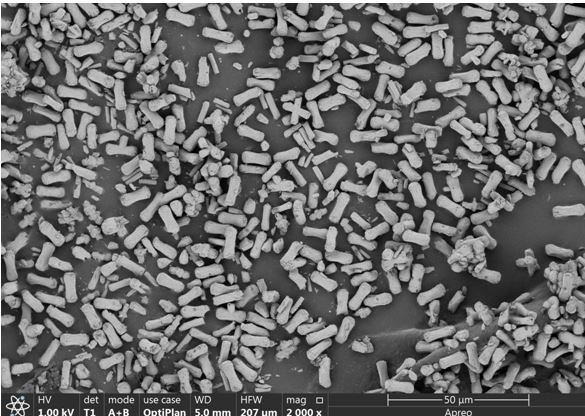

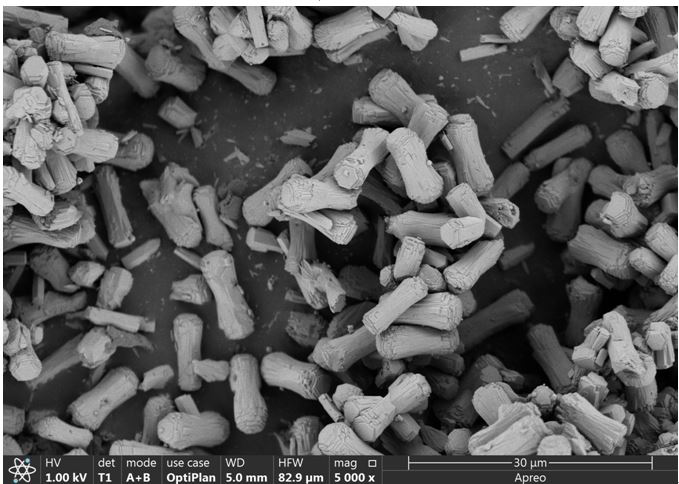

[0060] like figure 1 , figure 2 A...

Embodiment 2

[0063] The preparation conditions and preparation process of this example are the same as those of Example 1, the difference is that a small amount of H-SSZ-13 molecular sieve is added to the uniform sol-gel as a seed crystal. like Figure 5 Shown is a photo of the microscopic morphology of the msect-4 molecular sieve product prepared in Example 2, and it can be seen that the morphology is composed of lamellar stacking.

Embodiment 3

[0065] The preparation conditions and preparation process of this example are the same as those of Example 1, except that OSDA is not added.

[0066] like Image 6 As shown in the photo of the microscopic morphology of the msect-4 molecular sieve product prepared in Example 3, it can be observed that the two ends are thick and the middle is thin, and SEM characterization shows that the product presents a regular bone rod-like morphology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com