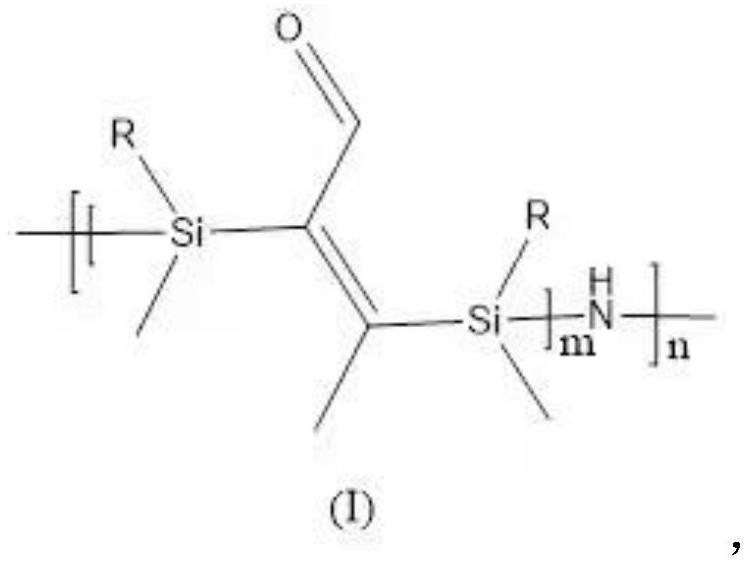

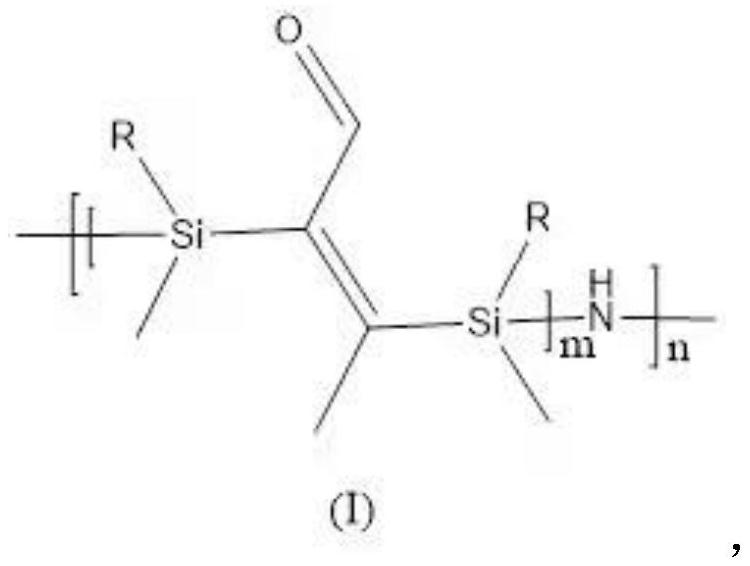

Hydrophobic and oleophobic organic polysilazane and preparation method thereof

A polysilazane, hydrophobic and oleophobic technology, which is applied in the preparation of the polysilazane, in the field of hydrophobic and oleophobic organopolysilazane, can solve the problem that the potential application value of polysilazane has not been effectively developed, and achieves Excellent hydrophobicity and oleophobicity, the effect of a wide range of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a 500ml three-necked flask, add 150ml tetrahydrofuran and 60ml n-butyllithium (2.5mol / L), under nitrogen protection, mix 50ml tetrahydrofuran and 26.3g 2,2,3-trichlorobutanal at -78°C The solution was slowly added dropwise into the three-necked flask. After the dropwise addition, keep the low temperature and continue to stir for 2 hours, gradually raise the temperature to 20° C. and continue to stir for 10 hours to obtain a mixed solution.

[0023] Add 100ml of tetrahydrofuran and 48.4g of dimethyldichlorosilane into a 500ml three-necked flask, keep the system at -5°C in a low-temperature bath, slowly add the above mixed solution dropwise under nitrogen protection, and continue stirring for 3 hours at -5°C after the dropwise addition Afterwards, heat up to 20°C and continue stirring for 10 hours, let stand to separate layers, transfer the upper layer to another clean and dry 500ml three-neck flask under nitrogen protection, wash the precipitate three times with tetra...

Embodiment 2

[0028] In a 500ml three-necked flask, add 150ml tetrahydrofuran and 60ml n-butyllithium (2.5mol / L), under nitrogen protection, mix 50ml tetrahydrofuran and 26.3g 2,2,3-trichlorobutanal at -78°C The solution was slowly added dropwise into the three-necked flask. After the dropwise addition, keep the low temperature and continue to stir for 2 hours, gradually raise the temperature to 20° C. and continue to stir for 10 hours to obtain a mixed solution.

[0029] Add 100ml of tetrahydrofuran and 53.7g of methylethyldichlorosilane into a 500ml three-necked flask, keep the system at -5°C in a low-temperature bath, slowly add the above mixed solution dropwise under nitrogen protection, and continue stirring at -5°C for 3 After 1 hour, raise the temperature to 20°C and continue to stir the reaction for 10 hours, let stand to separate layers, and transfer the upper layer to another clean and dry 500ml three-neck flask under the protection of nitrogen, wash the precipitate three times wi...

Embodiment 3

[0034] In a 500ml three-necked flask, add 150ml tetrahydrofuran and 60ml n-butyllithium (2.5mol / L), under nitrogen protection, mix 50ml tetrahydrofuran and 26.3g 2,2,3-trichlorobutanal at -78°C The solution was slowly added dropwise into the three-necked flask. After the dropwise addition, keep the low temperature and continue to stir for 2 hours, gradually raise the temperature to 20° C. and continue to stir for 10 hours to obtain a mixed solution.

[0035] Add 100ml of tetrahydrofuran and 58.9g of methylpropyl dichlorosilane into a 500ml three-necked flask, keep the system at -5°C in a low-temperature bath, slowly add the above mixed solution dropwise under nitrogen protection, and continue stirring at -5°C for 3 After 1 hour, raise the temperature to 20°C and continue to stir the reaction for 10 hours, let stand to separate layers, and transfer the upper layer to another clean and dry 500ml three-neck flask under the protection of nitrogen, wash the precipitate three times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com