Cable material composition for automobile wire harness and preparation method thereof

A technology for cable materials and automotive wires, which is applied in the field of cable material compositions for automotive wiring harnesses and its preparation, and can solve the problems of loss of polymer mechanical properties, complicated preparation methods of organophosphorus nitrogen flame retardants, reduction of polymer toughness, and tensile strength Intensity and other issues to achieve the effect of improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] The present invention also provides a preparation method of the cable material composition for the automobile wire harness, comprising the following steps:

[0096] S1. In parts by weight, put EPDM rubber, ethylene-vinyl acetate copolymer, silicon-aluminum composite inorganic flame retardant, antioxidant, and plasticizer into the mixer, heat to 90-120°C, and stir for 5 -20 minutes, cooled to room temperature to obtain the mixture;

[0097] S2. Put the mixture obtained in step S1 into a twin-screw extruder, and carry out plasticizing and granulation at 120-180° C. and a rotating speed of 200-500 r / min to obtain the cable material composition for automobile wiring harness.

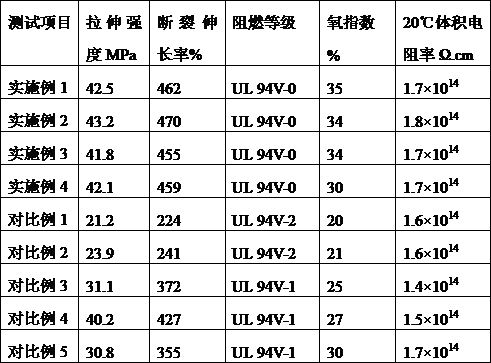

Embodiment 1

[0100] A cable material composition for automotive wiring harnesses in this embodiment is prepared from the following raw materials in parts by weight:

[0101] 40 parts by weight of EPDM rubber;

[0102] 70 parts by weight of ethylene-vinyl acetate copolymer;

[0103] 120 parts by weight of silicon-aluminum composite inorganic flame retardant;

[0104] Antioxidant 0.8 parts by weight;

[0105] 3 parts by weight of plasticizer;

[0106] 2 parts by weight of coupling agent;

[0107] Wherein, the silicon-aluminum composite inorganic flame retardant is prepared by the following method:

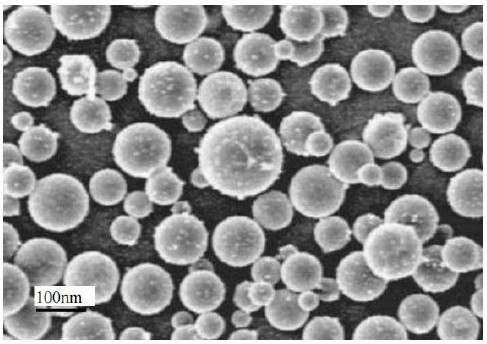

[0108] 1) Preparation of modified carbon nanotubes:

[0109] The carbon nanotubes are soaked in hydrofluoric acid for 12 hours, washed and dried, placed in the mixed acid of nitric acid and sulfuric acid, boiled for 2 hours, the carbon nanotubes are taken out, cleaned and dried to obtain the modified carbon nanotubes.

[0110] Wherein, the carbon nanotubes are commercially available multi-a...

Embodiment 2

[0131] The difference between this example and Example 1 lies in the proportion of each raw material in the cable material composition for automobile wiring harnesses, and only the differences are listed below.

[0132] A cable material composition for automobile wiring harness provided in this embodiment is prepared from the following raw materials in parts by weight:

[0133] 50 parts by weight of EPDM rubber;

[0134] 75 parts by weight of ethylene-vinyl acetate copolymer;

[0135] 130 parts by weight of silicon-aluminum composite inorganic flame retardant;

[0136] 1 part by weight of antioxidant;

[0137] Plasticizer 4 parts by weight;

[0138] 3 parts by weight of coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com