Combined crystallization tank for polycrystal rock sugar

A technology of polycrystalline rock sugar and crystallization tank, which is applied in sugar crystallization, sugar production, food science and other directions, can solve the problems of low yield of polycrystalline rock sugar, loose crystal structure, slow crystallization speed, etc., and achieves good crystal shape, The effect of product quality improvement and crystallization efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

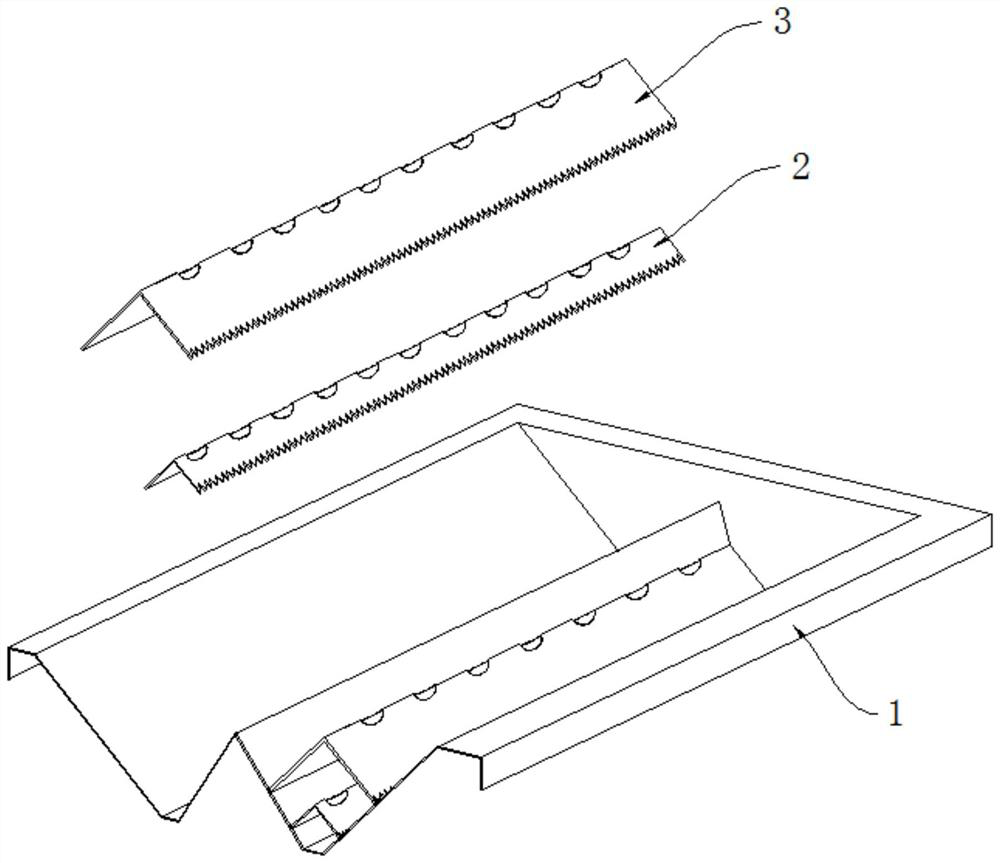

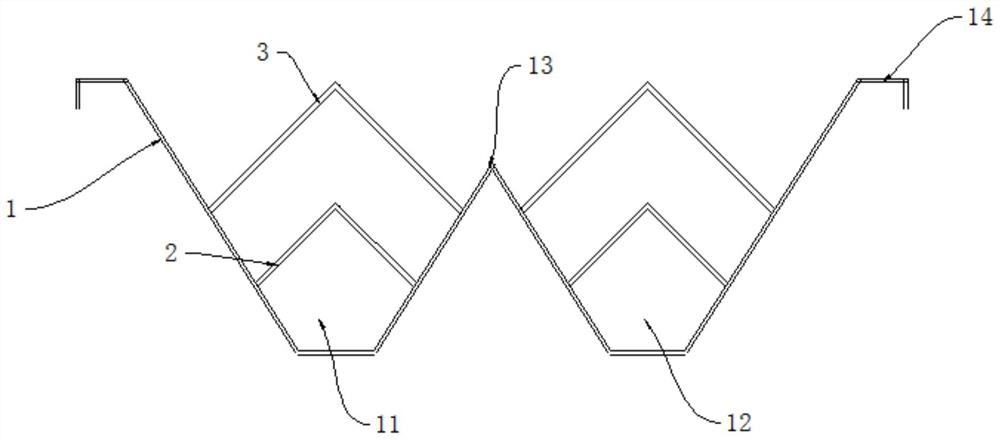

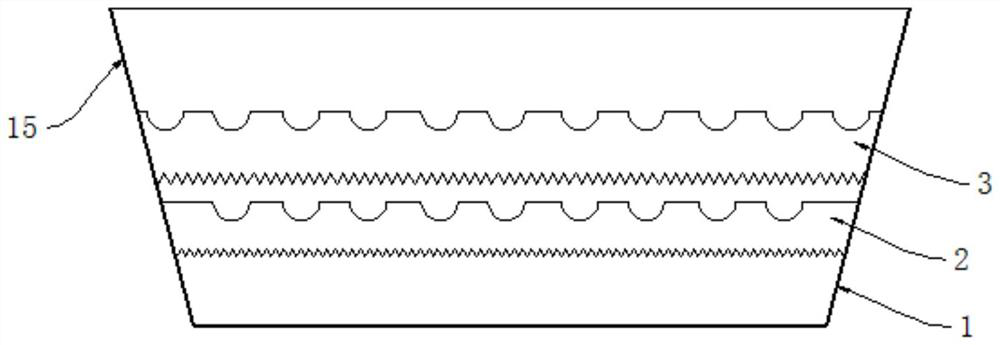

[0029] Such as Figure 1-4 As shown, the present embodiment designs a combined crystallization tank for polycrystalline rock sugar, including structures such as a W-shaped tank body 1 and a V-shaped piece.

[0030]The W-shaped tank body 1 is provided with two crystallization tank cavities; the two crystallization tank cavities are horizontally juxtaposed long tanks, and the notches of each crystallization tank cavity are flaring and set upward; The W-shaped tank body 1 is an independent tank structure, which can be transferred to different positions according to the needs of the production process steps or production line settings, so as to realize the flow between the process flows according to the required production process. In this scheme, only two crystallization tank cavities are used as long grooves side by side, so that it is convenient for workers on both sides of the conveying line on the production line to operate the crystallization tank cavities, and in this schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com