Dustproof net capable of being completely biodegraded and preparation method thereof

A biodegradable, dust-proof mesh technology, applied in the manufacture of rayon, conjugated synthetic polymer rayon, knitting, etc., can solve the problems of non-reuse, white garbage polluting the environment, pollution, etc., and achieve excellent mechanical properties and Water resistance and heat resistance, reducing white pollution and saving petrochemical resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

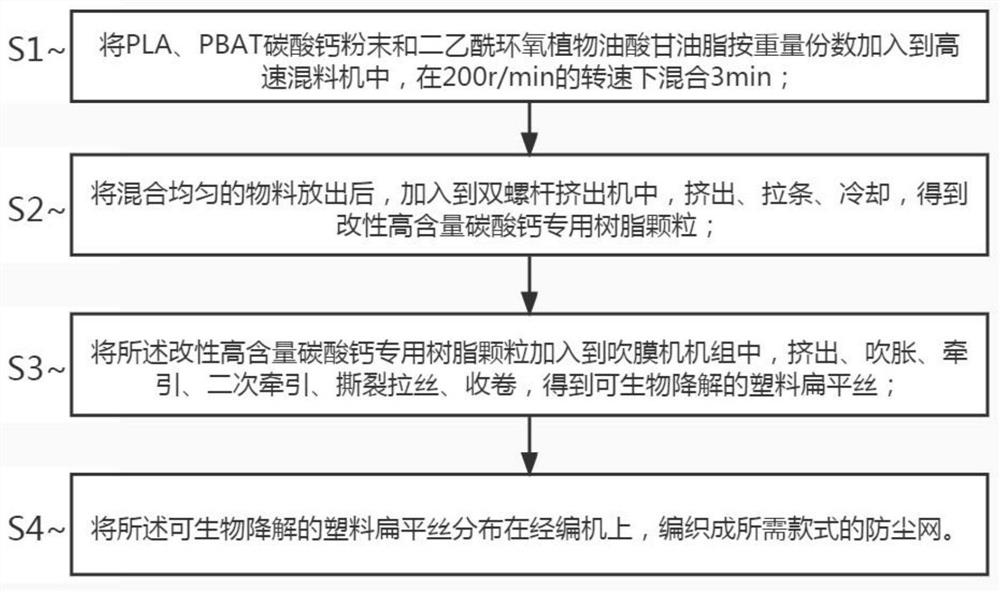

[0020] Such as figure 1 Shown, a fully biodegradable dust-proof net and preparation method thereof, said dust-proof net is made of the following components by weight: 8 parts of starch-based PLA, 62 parts of bio-based PBAT, 25 parts of calcium carbonate powder 5 parts, 5 parts of diacetyl epoxy vegetable oleic acid glycerides. The particle size of the calcium carbonate powder is 3000 mesh.

[0021] The preparation method of described dust-proof net comprises the steps:

[0022] S1. Add starch-based PLA, bio-based PBAT, calcium carbonate powder and diacetylepoxy vegetable olein into a high-speed mixer in parts by weight, and mix for 3 minutes at a speed of 200r / min;

[0023] S2. After releasing the uniformly mixed material, add it to a twin-screw extruder, extrude, pull, and cool to obtain special resin particles for modified high-content calcium carbonate;

[0024] S3, adding the modified high-content calcium carbonate special resin particles into the film blowing machine u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com