Activated carbon regeneration system and regeneration method thereof

A regeneration system and activated carbon technology, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve problems such as insufficient mixing reactions, affecting mixing reactions, and slow production efficiency, so as to improve reaction efficiency and avoid accumulation. Block, improve the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

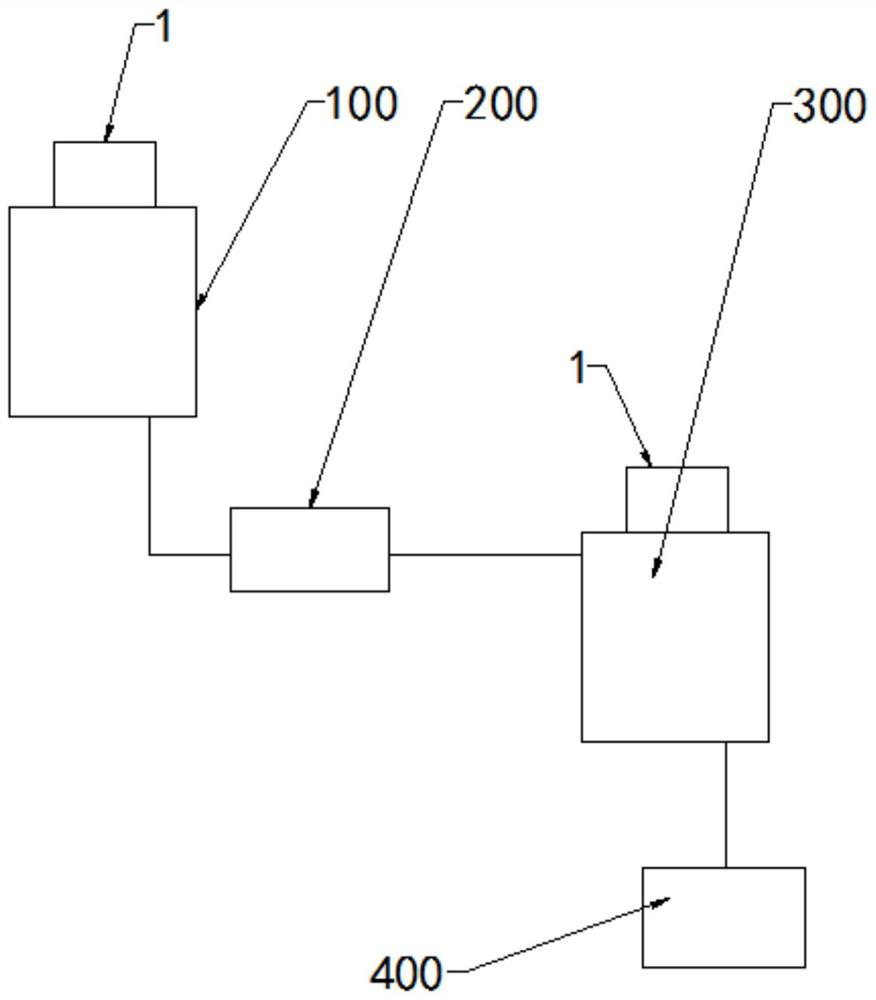

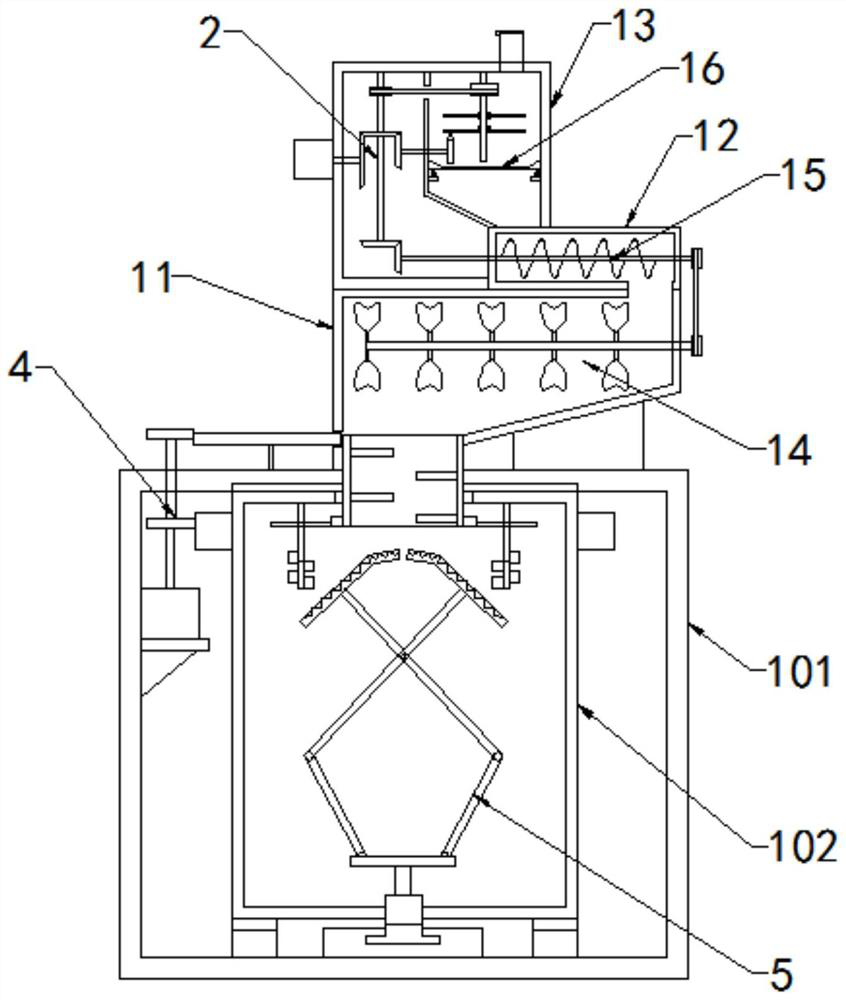

[0041] Such as Figure 1 to Figure 5 As shown, the present invention discloses an activated carbon regeneration system. In a specific embodiment of the present invention, it includes a first reaction kettle 100, a first drying and filtering device 200, a second reaction kettle 300, and a second drying and filtering device connected in sequence. 400, the first reaction kettle 100 and the second reaction kettle 300 have the same structure, the first drying and filtering device 200 and the second drying and filtering device 400 have the same structure and are used to filter materials and dry the solid obtained after filtering, The first reactor 100 and the second reactor 300 are all equipped with a stirring device 5; also include a feeding mechanism 1, which is arranged on the first reactor 100 and the second reactor 300, and is used to beat the powdery material Scatter and add to the stirring device 5 in the first reactor 100 and the second reactor 300.

[0042] In this embodim...

Embodiment 2

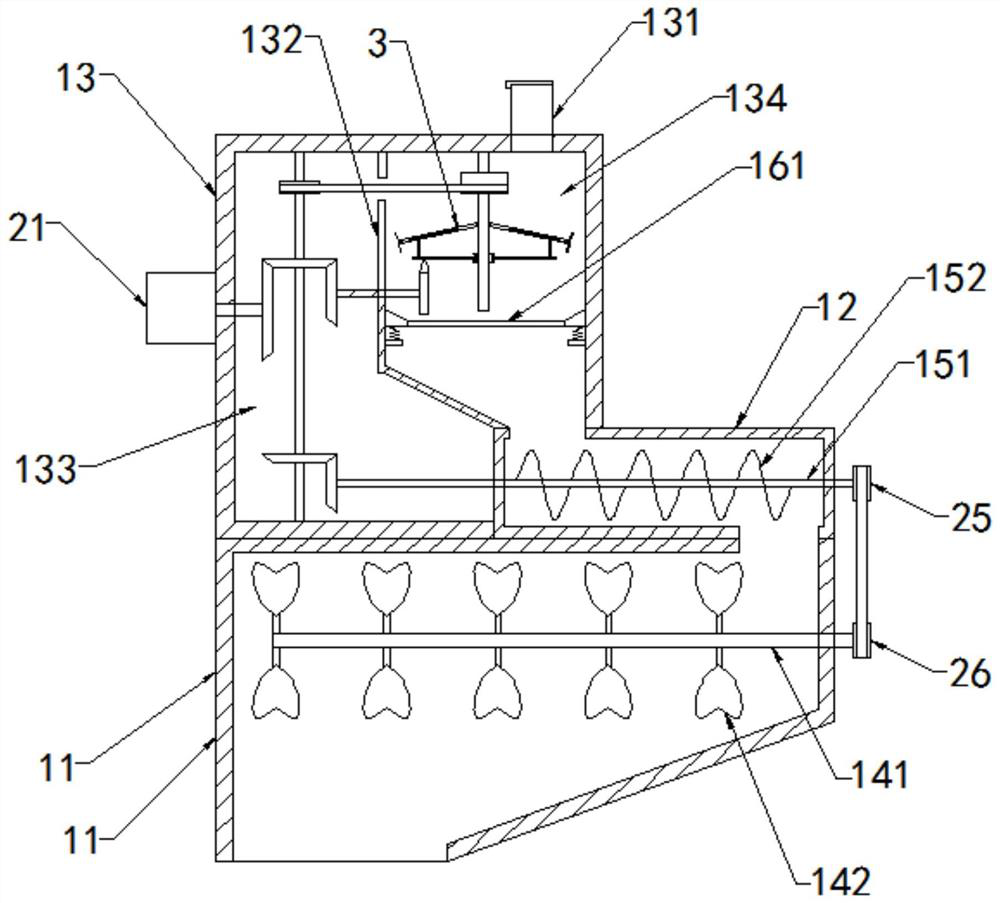

[0052] Such as Figure 5 ~ Figure 8 As shown, in this embodiment, the first reaction kettle 100 includes a housing 101, and the feeding mechanism 1 is installed on the upper end of the housing 101; On the bottom wall of the housing 101; the material distribution pipe 103 is installed on the upper end of the mixing drum 102 through bearing rotation, and communicates with the mixing drum 102 and the feeding mechanism 1. 103 inner walls are evenly equipped with a breaking rod; the rotating mechanism 4 is used to control the rotation of the material distribution pipe 103 and the mixing drum 102; Two motors 41 are installed on the inner side wall of the housing 101; the first rotating rod 42 is vertically arranged on the housing 101 and rotates under the control of the second motor 41; The first transmission gear 43 in the 101 and the second transmission gear 44 located at the upper end of the housing 101, the first transmission gear 43 is engaged with the meshing transmission on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com