Biomass energy raw material treatment device

A raw material processing, biomass energy technology, applied in grain processing, chemical/physical process, transportation and packaging, etc., can solve problems affecting energy conversion rate, etc., to achieve the effect of enhancing the effect of crushing and stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

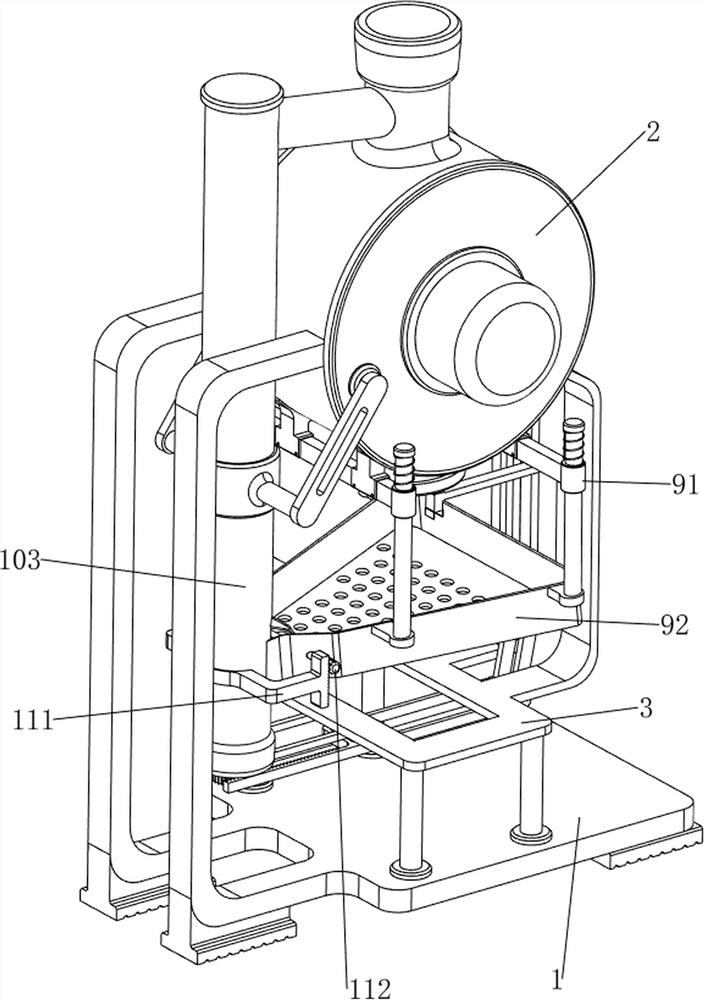

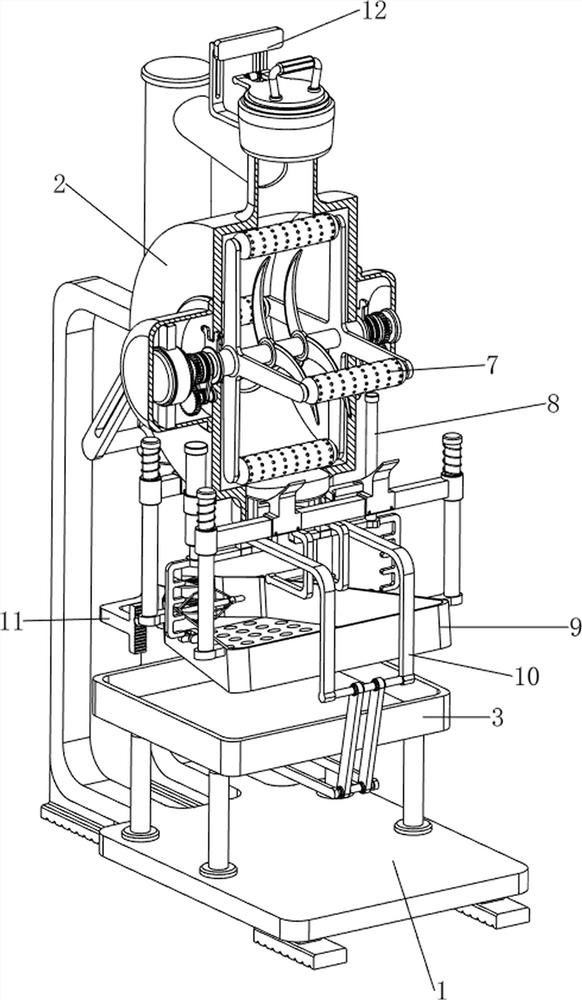

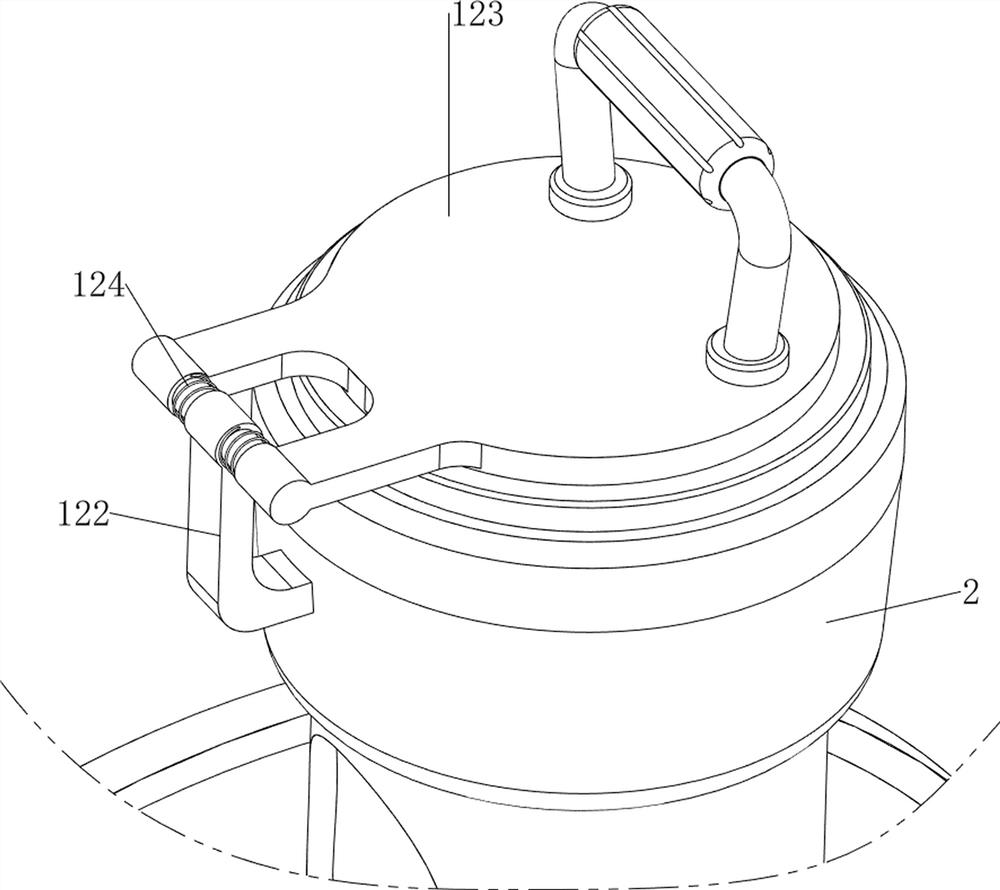

[0038] A biomass energy raw material processing device, such as figure 1 , figure 2 with image 3As shown, it includes a first support 1, a stirring frame 2, a second support 3, a drive motor 4, a rotating shaft 5, a cutter 6, a crushing mechanism 7 and a cutting mechanism 8, and the upper part of the first support 1 is fixed by means of A stirring frame 2 is provided, and the top and bottom of the stirring frame 2 are respectively provided with a feed inlet and a discharge port. A drive motor 4 is installed on the front side of the material frame 2 through bolts, and a rotating shaft 5 is connected between the output shaft of the drive motor 4 and the inner rear part of the material stirring frame 2. The middle part is provided with two cutters 6 by means of a key connection, and the cutters 6 are set as blades, a crushing mechanism 7 is provided between the stirring frame 2 and the rotating shaft 5, and a material cutting mechanism 8 is provided at the bottom of the stirr...

Embodiment 2

[0043] On the basis of Example 1, such as figure 1 , Figure 8 with Figure 9 As shown, a screening mechanism 9 is also included, and the screening mechanism 9 includes a second sliding sleeve 91, a material receiving frame 92, a compression spring 93, a moving block 94, a fourth support 95, a shifting block 96 and a second torsion spring 97, stirring The left and right sides of the bottom of the material frame 2 are welded and connected with a second sliding sleeve 91, and a material receiving frame 92 is slidably arranged between the second sliding sleeves 91. The bottom of the material receiving frame 92 is uniformly provided with sieve holes, and the second sliding sleeve 91 tops are all wound with compression spring 93, and compression spring 93 two ends are respectively connected with second sliding sleeve 91 and material receiving frame 92, and supporting frame 84 outer ends are all provided with moving block 94, and material receiving frame 92 bottom, front and rear b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com