Post-treatment method for improving densification degree of carbon nanotube fibers

A carbon nanotube fiber, carbon nanotube technology, applied in the direction of carbon nanotubes, chemical instruments and methods, nanocarbon, etc., can solve the problem that the microscopic voids of carbon nanotube fibers cannot be effectively removed, and the macroscopic electrical properties of carbon nanotube fibers are reduced. Can not effectively improve the degree of fiber densification and other problems, to achieve the effect of improving electron transmission efficiency, reducing the actual cross-sectional area, and improving the degree of densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

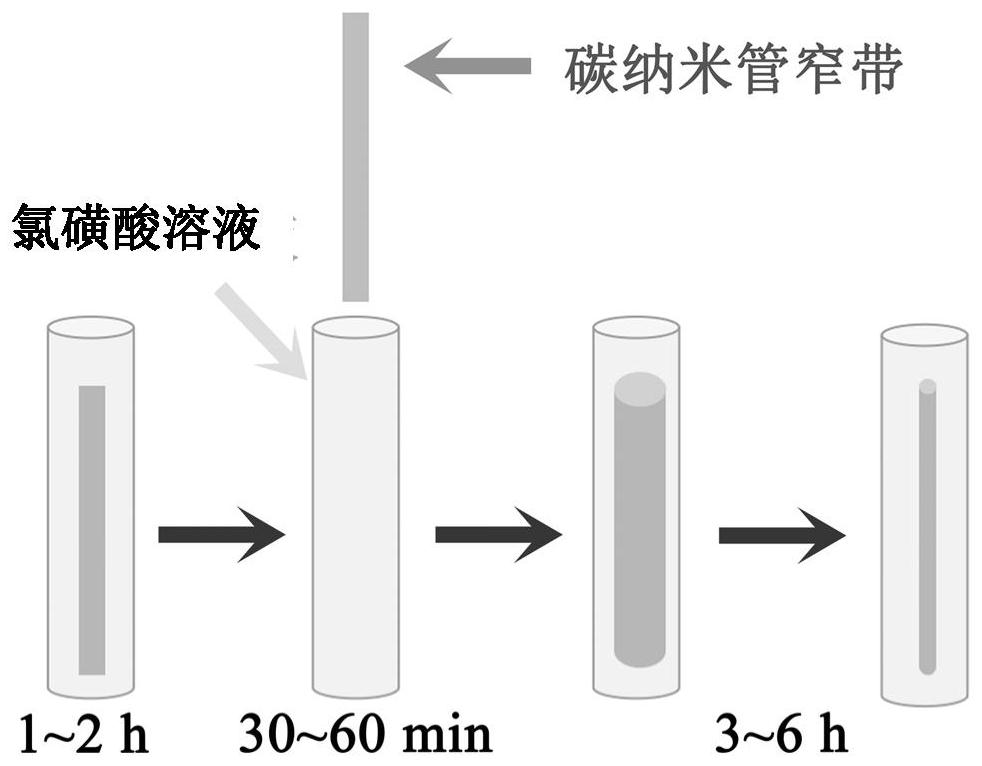

[0059] see figure 1 As shown, the specific technical steps of a post-processing method for improving the degree of densification of carbon nanotube fibers in this embodiment are:

[0060] (1) Pretreatment of carbon nanotube fibers

[0061] Take a carbon nanotube fiber with a length of 35-45 cm and slowly put it into a graduated cylinder filled with chlorosulfonic acid, and place it for about 1-2 hours, so that the chlorosulfonic acid can fully infiltrate the carbon nanotube fiber; then take out the carbon nanotube from the chlorosulfonic acid fiber, and stand in the air for about 30-60 minutes, so that the chlorosulfonic acid can fully react with the moisture in the air to generate concentrated sulfuric acid; after that, within 3-5 seconds at a faster rate (try within 3-5 seconds) Put the fiber into the chlorosulfonic acid solution completely to ensure that the reaction produces enough hydrogen chloride pressure) Put the carbon nanotube fiber back into the chlorosulfonic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com