Method for treating sodium bromide wastewater

A technology of sodium bromide and waste water, which is applied in chemical instruments and methods, filtration treatment, water/sewage treatment, etc., and can solve problems such as difficult treatment of concentrated waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

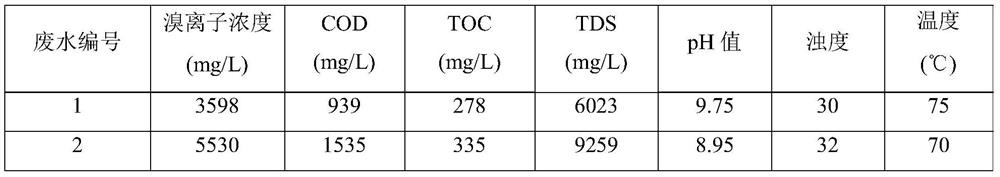

Embodiment 1

[0036] (1) Treat the waste water 1 through a gel separation tank, air flotation, flocculation sedimentation, filter cotton filtration, ultrafiltration, and reverse osmosis. The rubber separation tank is a corrugated inclined plate type rubber separation tank; the air flotation pressure is 0.35MPa; the dosage of the flocculant polyaluminum chloride (polyaluminum chloride 28, purchased from Gongyi City Filter Industry Co., Ltd.) is 800mg / L, Coagulant aid polyacrylamide (molecular weight 800-2000, purchased from Gongyi City Filter Industry Co., Ltd.) dosage is 5mg / L, stirring time is 8min, and standing for 25min; the filter cotton is made of polypropylene, and the filtration accuracy is 5μm; the ultrafiltration membrane is Coriolis MP 8081-102 ultrafiltration membrane with an operating pressure of 0.2MPa and a temperature of 25°C; the reverse osmosis membrane is Hyde Energy PROC10 reverse osmosis membrane with an operating pressure of 1.5MPa. The reverse osmosis produced water...

Embodiment 2

[0039] Wastewater 2 was treated in the same manner as in Example 1, except that the inter-electrode voltage in step (2) was 1.2V.

Embodiment 3

[0041] The same method as in Example 1 is adopted, except that the inter-electrode voltage in step (2) is 1.4V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com