Method for preparing high-temperature-resistant steel slag brick by utilizing accelerated carbonization

A high-temperature-resistant steel slag brick technology, which is applied in the field of preparing high-temperature-resistant cement-free steel slag bricks by accelerated carbonization, can solve the problems of low utilization rate of steel slag resources and insufficient high-temperature resistance of brick structures, so as to achieve sustainable development and maintenance. The effect of short time and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

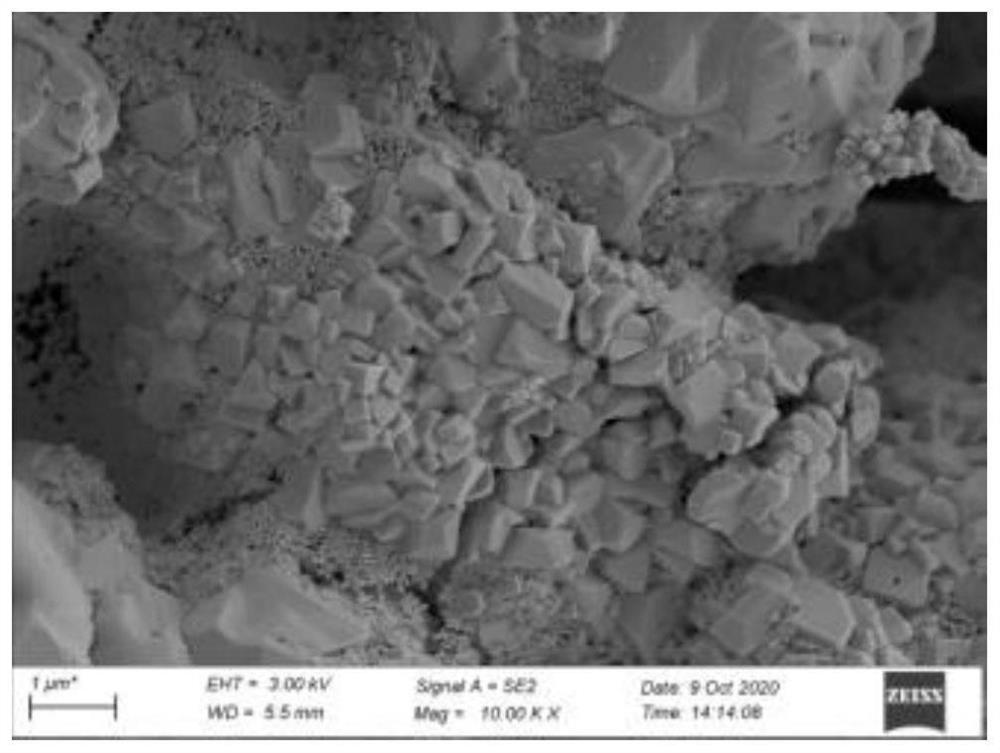

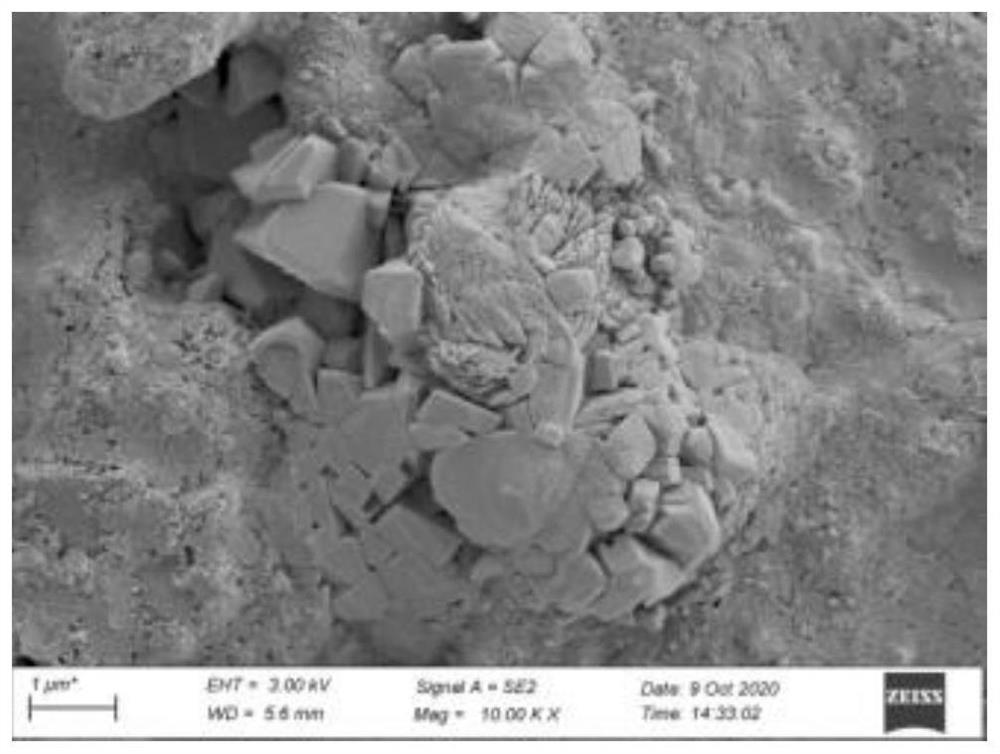

Image

Examples

Embodiment 1

[0018] A method for preparing high-temperature-resistant steel slag bricks by accelerated carbonization in this embodiment specifically includes the following steps:

[0019] Step 1, using finely ground converter steel slag powder as the raw material for making bricks, the average particle size of steel slag powder particles is 6 μm;

[0020] Step 2, mixing the steel slag powder with water at a water-to-solid ratio of 0.12, dividing the mixing water into two parts on average, and adding in twice, each stirring time is 30s, to form a mixture of steel slag powder and water;

[0021] Step 3: Weigh an appropriate amount of the mixture in step 2, pour the mixture into the mold and place it under the molding press, pressurize to 15MPa at a constant speed, keep the constant pressure for 20s, and then unload;

[0022] Step 4, immediately put the pressed test block into the temperature-controlled pressure carbonization reactor. The reaction kettle was heated to 70°C in advance and kep...

Embodiment 2

[0025] A method for preparing high-temperature-resistant steel slag bricks by accelerated carbonization in this embodiment specifically includes the following steps:

[0026] Step 1, using finely ground converter steel slag powder as the raw material for making bricks, the average particle size of steel slag powder particles is 17 μm;

[0027] Step 2, mixing the steel slag powder with water at a water-solid ratio of 0.12, adding water twice and stirring for 30 seconds each time to form a mixture of steel slag powder and water;

[0028] Step 3: Weigh an appropriate amount of the mixture in step 2, pour the mixture into the mold and place it under the molding press, pressurize to 12MPa at a constant speed, keep the constant pressure for 20s, and then unload;

[0029] Step 4, immediately put the pressed test block into the temperature-controlled pressure carbonization reactor. The reaction kettle was heated to 50°C in advance and kept at a constant temperature. After the test bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com