Color-adjustable organic room-temperature phosphorescent thin film material with hydrothermal stimulation response and preparation and application of color-adjustable organic room-temperature phosphorescent thin film material

A stimuli-responsive, thin-film material technology, applied in the field of room temperature phosphorescence, can solve problems such as the difficulty of light-emitting materials, and achieve the effects of low price, promotion of room temperature phosphorescence emission, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

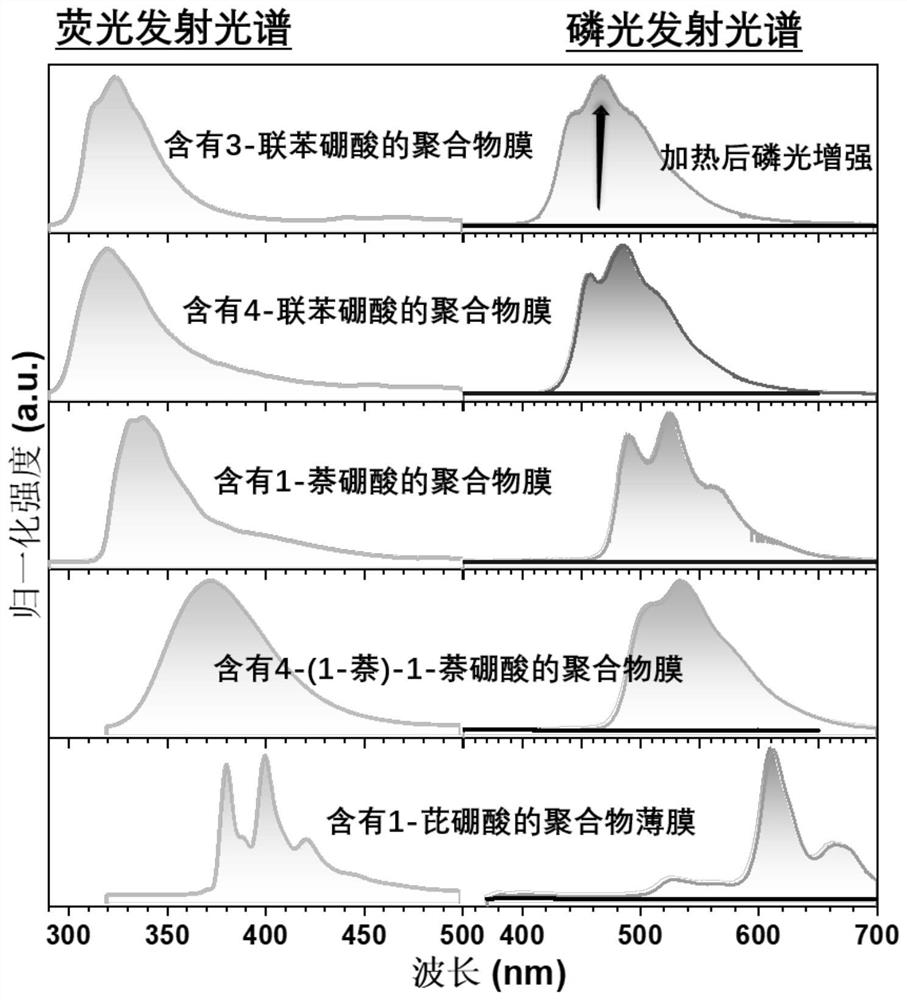

[0033] Example 1: Preparation method of organic room-temperature phosphorescent film material with adjustable color in response to hydrothermal stimulation:

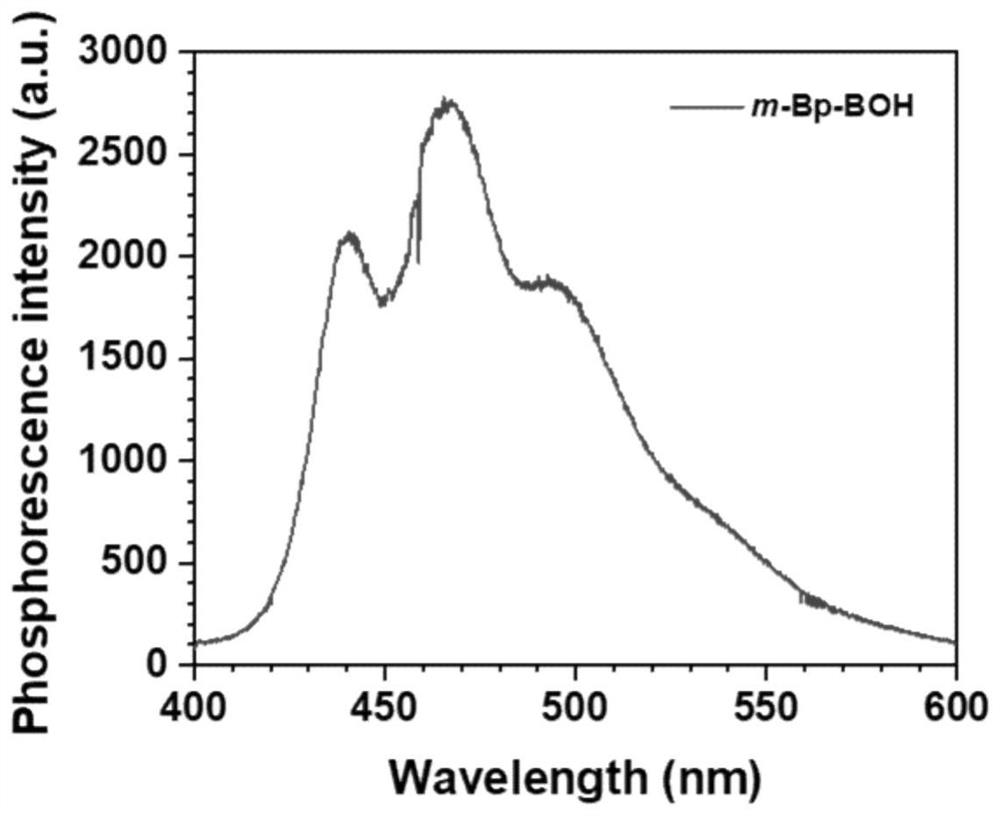

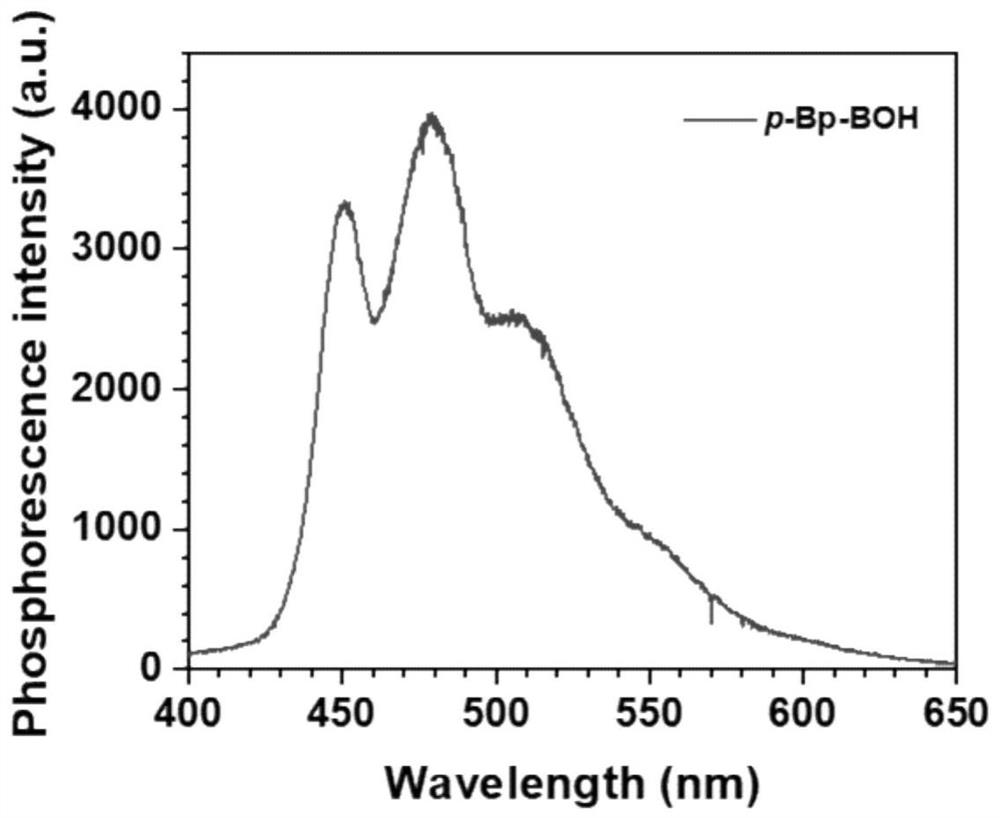

[0034] Phosphorescent film material Preparation of polymer film (m-Bp-BOH-PVA) with structural formula (VII) containing 3-biphenylboronic acid.

[0035]

[0036] Polyvinyl alcohol is selected as the rigid matrix polymer, and 3-biphenylboronic acid is selected as the phosphorescent chromophore. Stir 3 mL of 160 g / L polyvinyl alcohol aqueous solution, 4 mL of 1.25 g / L 3-biphenylboronic acid aqueous solution and 1 mL of ammonia water at 80°C for 30 min. Take 0.7mL of the prepared aqueous solution and drop it on the coverslip. Then, heat the coverslip at 80°C until all the water evaporates, and cool to room temperature to obtain a polymer film containing 3-biphenylboronic acid.

Embodiment 2

[0037] Example 2: Phosphorescent film material Preparation of polymer film (m-Bp-BOH-PVA) with structural formula (VII) containing 3-biphenylboronic acid. Polyvinyl alcohol is selected as the rigid matrix polymer, and 3-biphenylboronic acid is selected as the phosphorescent chromophore. Stir 3 mL of 500 g / L polyvinyl alcohol aqueous solution, 4 mL of 1 g / L 3-biphenylboronic acid aqueous solution and 0.5 mL of ammonia water at 65°C for 20 min. Take 0.7mL of the prepared aqueous solution and drop it on the coverslip. Then, heat the coverslip at 90°C until all the water evaporates, and cool to room temperature to obtain a polymer film containing 3-biphenylboronic acid.

Embodiment 3

[0038] Example 3: Phosphorescent film material Preparation of a polymer film (m-Bp-BOH-PVA) with structural formula (VII) containing 3-biphenylboronic acid. Polyvinyl alcohol is selected as the rigid matrix polymer, and 3-biphenylboronic acid is selected as the phosphorescent chromophore. Stir 3 mL of 300 g / L polyvinyl alcohol aqueous solution, 4 mL of 3 g / L 3-biphenylboronic acid aqueous solution and 5 mL of ammonia water at 90°C for 10 min. Take 0.7mL of the prepared aqueous solution and drop it on the coverslip. Then, heat the cover glass at 65°C until all the water evaporates, and cool to room temperature to obtain a polymer film containing 3-biphenylboronic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com