Phosphorescent material and preparation method thereof

A technology for phosphorescent materials and organic dyes, applied in the field of phosphorescent materials and their preparation, can solve problems such as molecular design of complex synthesis processes, and achieve the effects of reasonable cost, convenient preparation and large control space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for preparing a phosphorescent material in this embodiment includes the following steps:

[0038] (1) The polydimethyldiallyl ammonium chloride solution (as shown in formula II) of 15mL 35% mass fraction is placed in the potassium bromide solution of 1000mL 15g / L and is dialyzed, and gained product is placed in pure water again For dialysis, repeat the operation of redialysis in potassium bromide solution and pure water three times, and then dialyze in pure water five times to remove excess potassium bromide. The resulting solution was dried to obtain polydimethyldiallylammonium bromide (as shown in formula I-1).

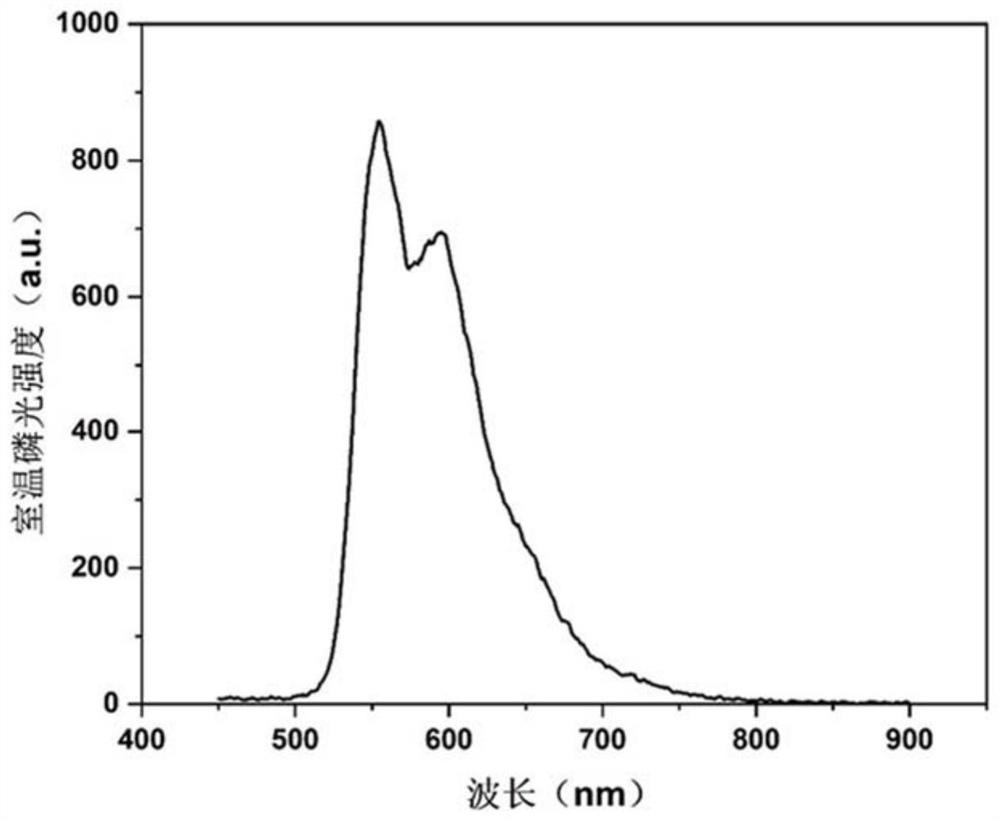

[0039] (2) Mix 40 μL of 2.25mol / L polydimethyldiallylammonium bromide solution and 20 μL of 7.50 mmol / L ethanol solution of naphthalene imine, dry at 40°C for 20 minutes, and then dry at 60°C °C for 10 minutes, and then vacuum-dried at 30 °C for 2 days to obtain a pure organic room-temperature phosphorescent material. Its phosphorescent emission ...

Embodiment 2

[0041] The method for preparing a phosphorescent material in this embodiment includes the following steps:

[0042] (1) The polydimethyldiallyl ammonium chloride solution (as shown in formula II) of 15mL 35% mass fraction is placed in the potassium bromide solution of 1000mL 15g / L and is dialyzed, and gained product is placed in pure water again For dialysis, repeat the operation of redialysis in potassium bromide solution and pure water three times, and then dialyze in pure water five times to remove excess potassium bromide. The resulting solution was dried to obtain polydimethyldiallylammonium bromide (as shown in formula I-1).

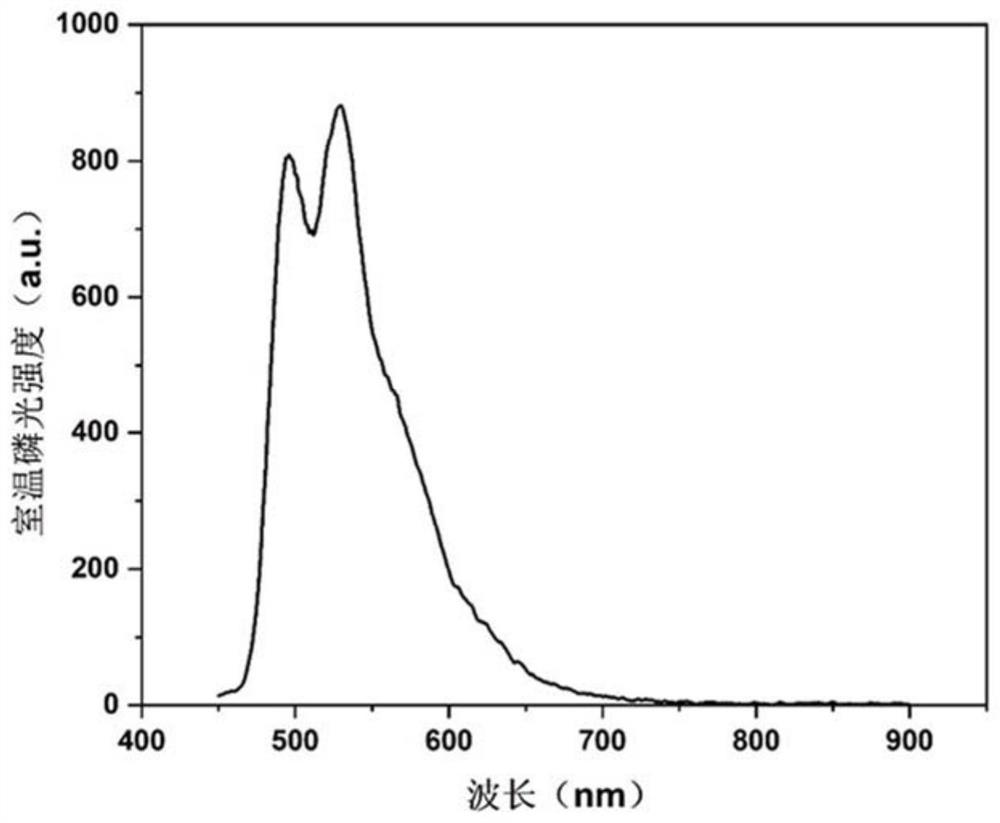

[0043] (2) 40 μL of 2.25mol / L polydimethyldiallylammonium bromide solution and 20 μL of 15.00mmol / L ethanol solution of S-binaphthol were mixed uniformly, dried at 40°C for 20 minutes, and then Dry at 60°C for 10 minutes, and then vacuum dry at 30°C for 2 days to obtain a pure organic room temperature phosphorescent material. Its phosphorescent e...

Embodiment 3

[0045] The method for preparing a phosphorescent material in this embodiment includes the following steps:

[0046](1) The polydimethyldiallyl ammonium chloride solution (as shown in formula II) of 15mL 35% mass fraction is placed in the potassium bromide solution of 1000mL 15g / L and is dialyzed, and gained product is placed in pure water again For dialysis, repeat the operation of redialysis in potassium bromide solution and pure water three times, and then dialyze in pure water five times to remove excess potassium bromide. The resulting solution was dried to obtain polydimethyldiallylammonium bromide (as shown in formula I-1).

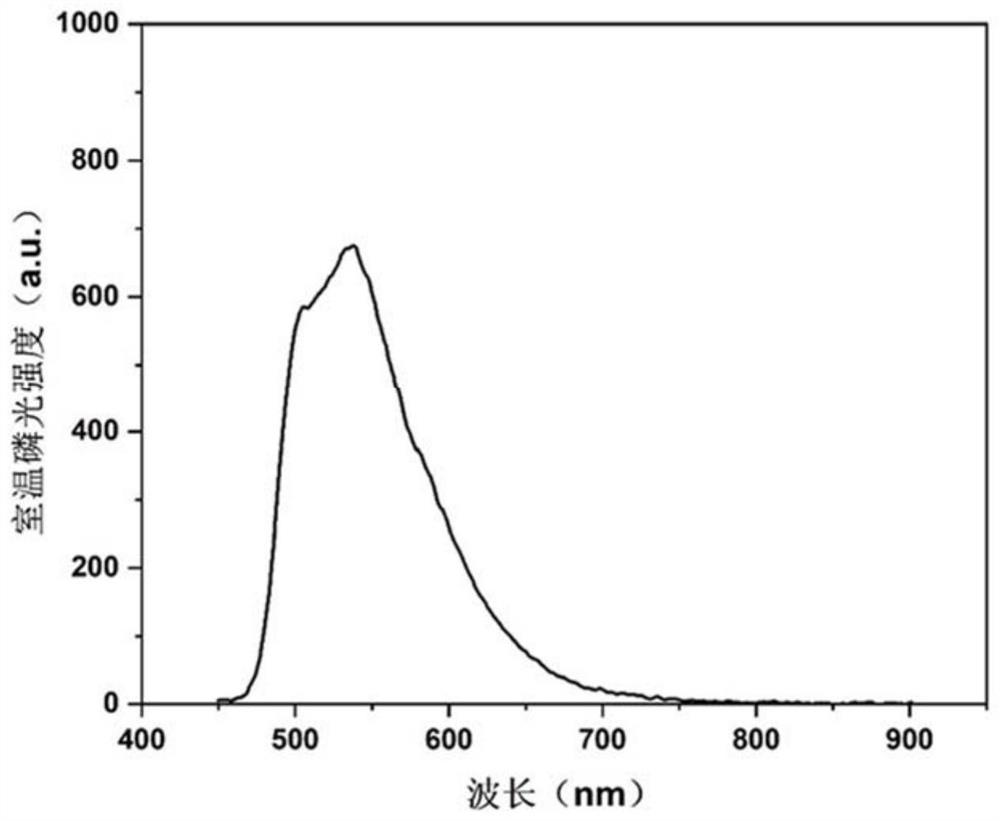

[0047] (2) Mix 40 μL of 2.25 mol / L polydimethyldiallylammonium bromide solution and 20 μL of 15.00 mmol / L ethanol solution of 6,7-dihydroxycoumarin, and dry at 40°C 20 minutes, and then dried at 60° C. for 10 minutes, and then vacuum-dried at 30° C. for 2 days to obtain a pure organic room-temperature phosphorescent material. Its phosphorescent em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com