A light-tunable room temperature phosphorescent carbon dot material and its preparation method and application

A technology of room temperature phosphorescence and carbon dots, which is applied in the direction of luminescent materials, fluorescence/phosphorescence, and material analysis through optical means. It can solve the problems of cumbersome experimental steps, single material form, and long cycle, and achieve simple operation steps and cheap raw materials. , the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Weigh 7.5g of potassium nitrate and 2.5g of sodium chloride powder (melting temperature is 350°C) and place them in a sample bottle, add distilled water, stir well, then carry out vacuum freeze-drying, and obtain a uniform mixed salt system after grinding. Weigh 0.5g of 1,2,4-triaminobenzene, grind it with the mixed salt system, place it in a crucible, raise the temperature to 350°C in a muffle furnace at a rate of 10°C, and After keeping the temperature for 3 hours, the temperature was cooled to room temperature to obtain carbon dots with room temperature phosphorescence.

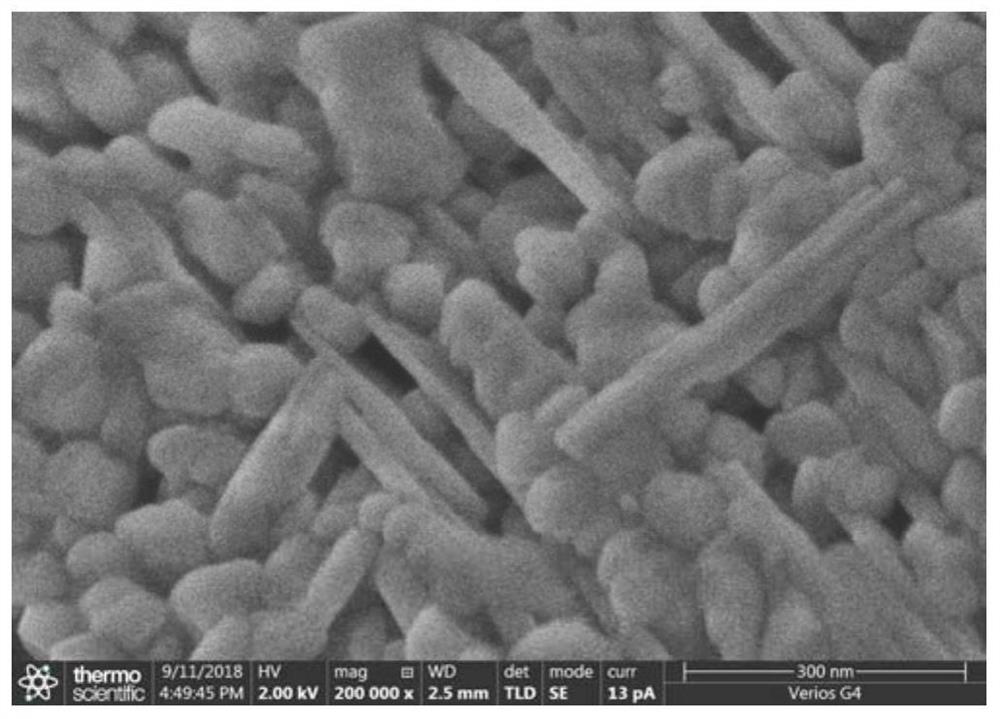

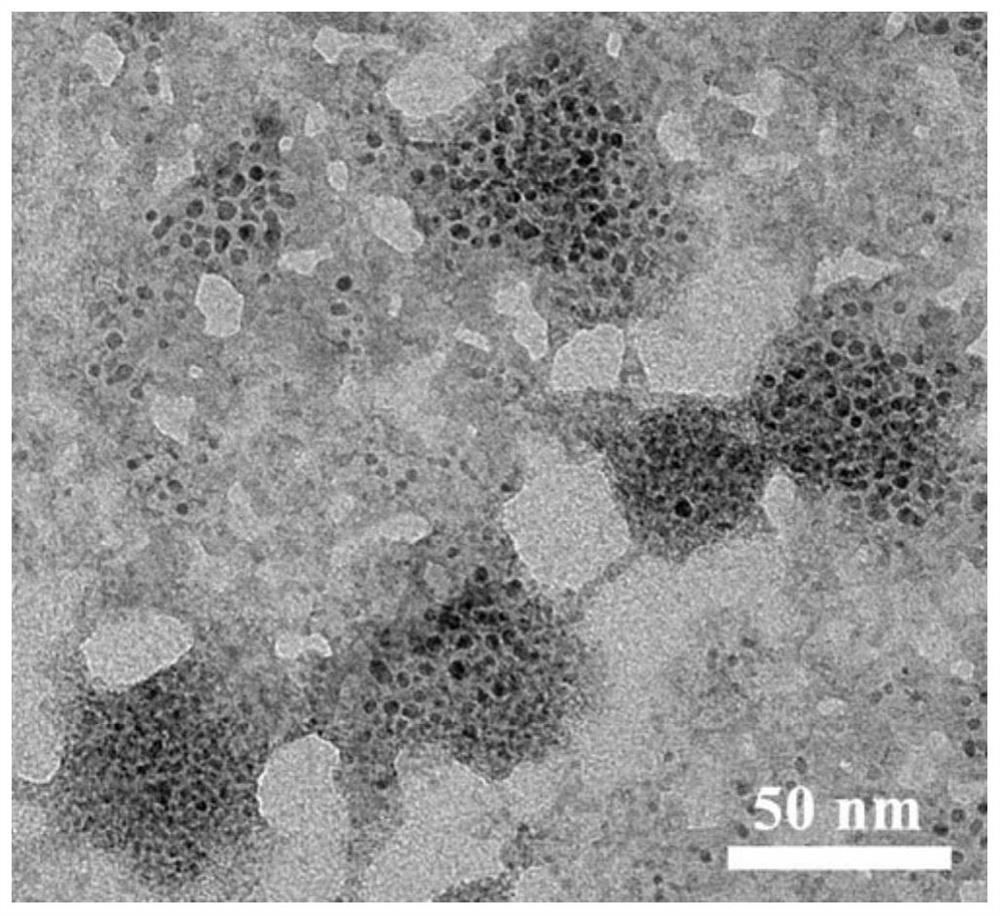

[0044] The scanning electron microscope image of the obtained powder is shown in figure 1As shown, the obtained material is oval or rod-shaped, with a size of about 50 nm. Disperse the powder in acetone and test it with a transmission electron microscope, the results are as follows figure 2 , indicating that carbon quantum dots with a diameter of about 2-3nm are dispersed in a molten salt matrix ...

Embodiment 2

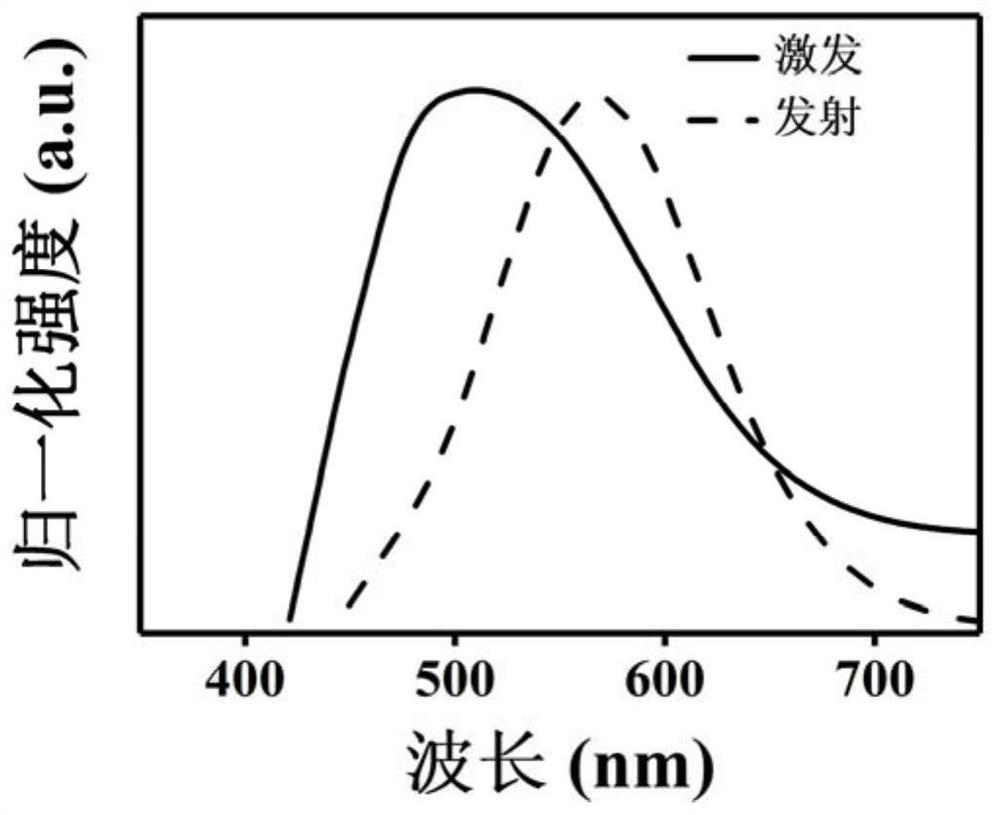

[0048] Weigh 7.5g of potassium nitrate and 2.5g of sodium chloride powder (melting temperature is 350°C) and place them in a sample bottle, add distilled water, stir well, then carry out vacuum freeze-drying, and obtain a uniform mixed salt system after grinding. Weigh 0.5g of citric acid, grind it with the mixed salt system, place it in a crucible, and keep it at 350°C for 3 hours in a muffle furnace with a heating rate of 10°C. When the temperature is cooled to room temperature, it has Room-temperature phosphorescent carbon-based nanomaterials. The result is as Figure 8 As shown, the best fluorescence emission of the prepared material is at 477nm, and the best phosphorescence emission is at 557nm (the optimum excitation wavelength is 400nm). The powder is white under the fluorescent lamp. Under the 395nm ultraviolet lamp, the obtained powder shows green fluorescence. When the ultraviolet lamp is turned off, the phosphorescence of the powder changes from green to yellow.

Embodiment 3

[0050] Weigh 7.5g of potassium nitrate and 2.5g of sodium chloride powder (melting temperature is 350°C) and place them in a sample bottle, add distilled water, stir well, then carry out vacuum freeze-drying, and obtain a uniform mixed salt system after grinding. Weigh 0.5g of ethylenediaminetetraacetic acid, grind it with the mixed salt system, place it in a crucible, and keep it in a muffle furnace at 350°C for 3 hours at a heating rate of 10°C. When the temperature is cooled to room temperature, That is, a carbon-based nanomaterial with room temperature phosphorescence is obtained. The result is as Figure 9 As shown, the best fluorescence emission of the prepared material is at 432nm, and the best phosphorescence emission is at 516nm (the optimum excitation wavelength is 365nm). The powder is white under the fluorescent lamp. Under the 365nm ultraviolet lamp, the obtained powder shows blue fluorescence. When the ultraviolet lamp is turned off, the phosphorescence of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com