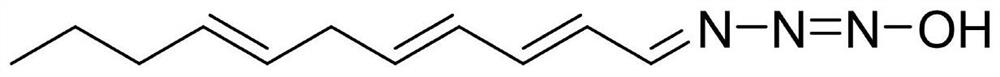

Preparation method of triazole C

A technology of nitrogen bacteria and bacterial liquid, applied in the field of microbial fermentation technology and separation, can solve the problems of hindering the research and application of triazocin, long fermentation time of triazocin C, complicated separation and purification process, etc., and achieves high implementation power. , Simple operation, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

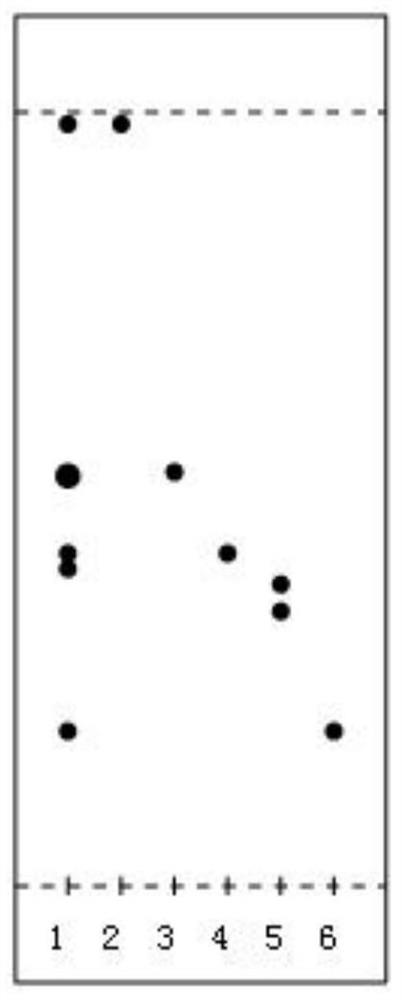

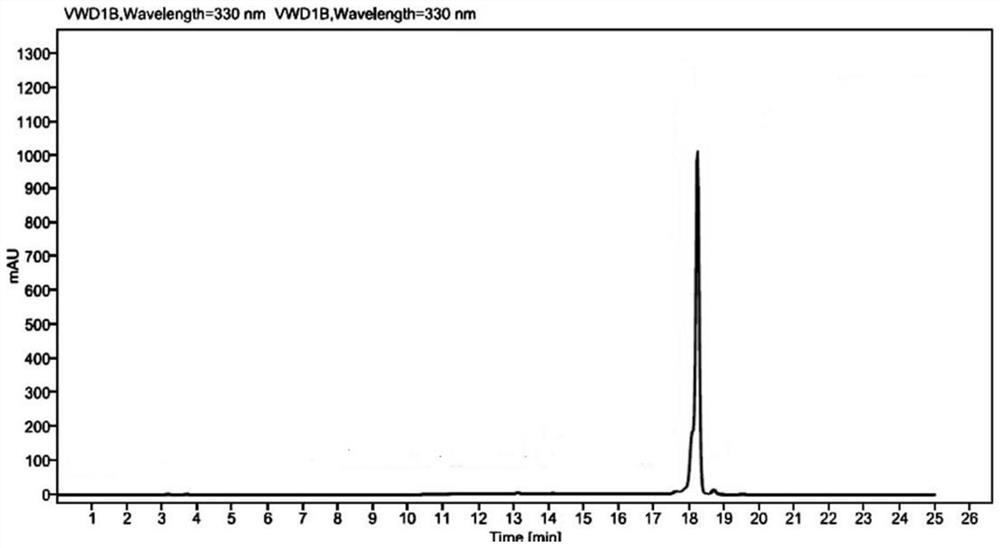

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of embodiment 1, azocin C

[0028] Step 1. Activation of the strain

[0029] Each tube containing 3 mL of TSB medium was sterilized at 121°C for 20 minutes and then used for later use. Streptomyces aureus preserved in the glycerol tube was inoculated into the above test tube with an inoculum size of 20 uL per tube, and cultured on a shaker overnight to obtain liquid bacteria solution, the rotational speed of the shaker culture was 180 rpm / min, and the culture temperature was 30°C.

[0030] Step 2, fermentation and cultivation:

[0031] Prepare liquid ISP2 medium, and sterilize at 115°C for 20 minutes for backup. The liquid bacterial liquid obtained by activating the strain in step 1 was transferred to a 250 mL Erlenmeyer flask containing 50 mL of ISP 2 liquid medium at a volume ratio of 2%, and cultured on a shaking table to obtain a fermentation liquid. A total of 60 L was fermented, the rotational speed of the rotary shaker was 180 rpm / min, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com