ITO conducting film glass plate sputtering cavity structure

A sputtering chamber and conductive film technology, applied in the field of ITO conductive film glass plate sputtering chamber structure, can solve the problems of substrate scratches, inability to fix the substrate, and waste of the remaining amount in the middle area of the target, so as to avoid scratches Spend and damage, improve target utilization, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

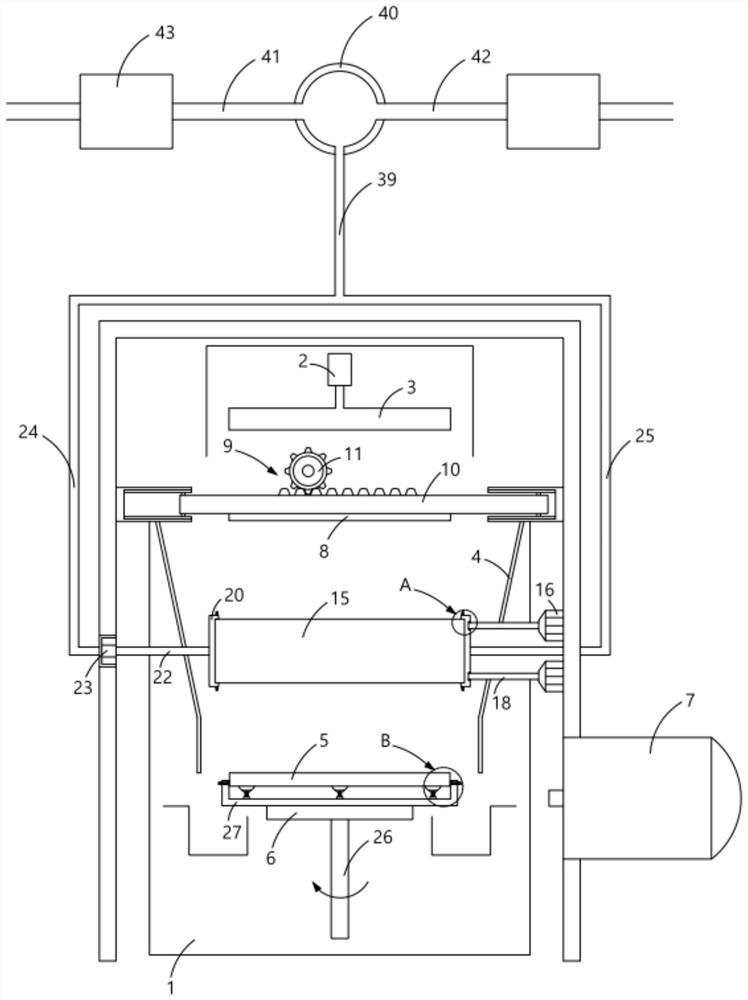

[0024] see Figure 1 to Figure 6 , the present invention provides a technical solution:

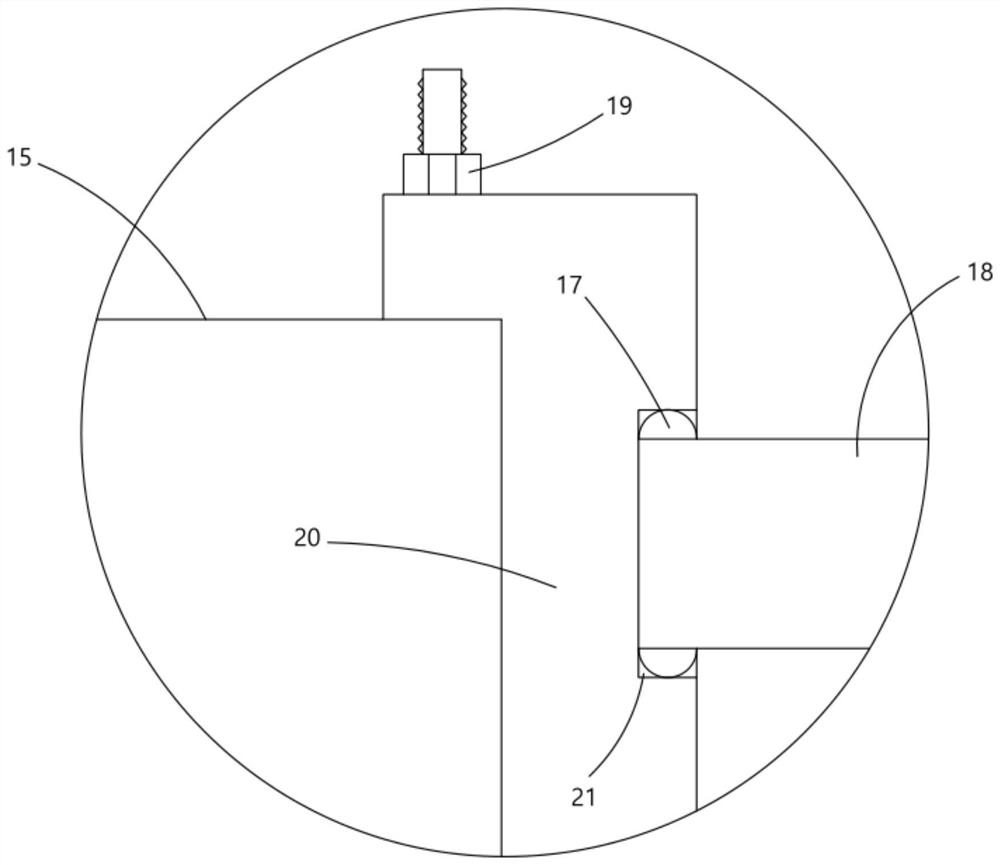

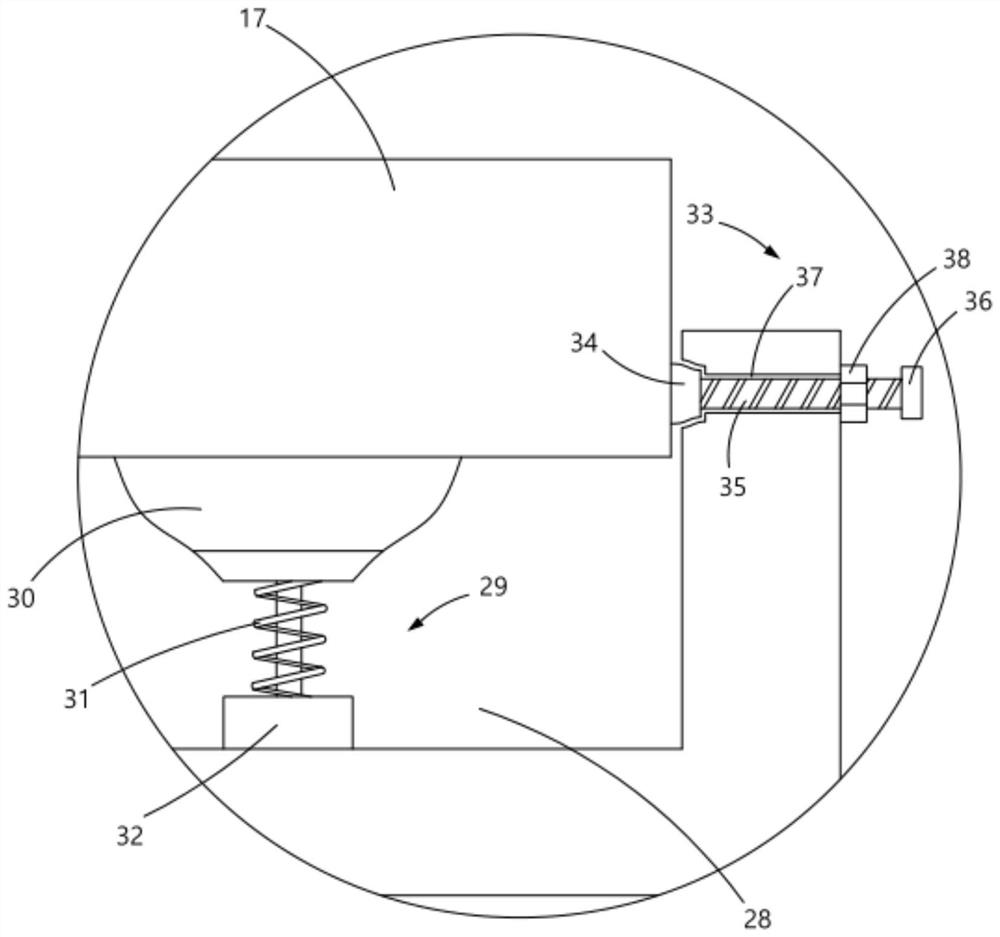

[0025] A kind of ITO conductive film glass plate material sputtering cavity structure, such as figure 1 As shown, it includes a cavity 1, a driving device 2 and a magnetic member 3 installed on the upper part of the cavity 1, a guard plate 4, a substrate 5 and a target 8 installed in the cavity 1, and a The cryopump 7 on the side wall of the body 1, the driving device 2 is fixedly connected to the magnetic part 3, the guard plate 4 is installed between the substrate 5 and the target 8, and the substrate 5 is generally calcium-based or Silicon boron base, the target material 8 is indium and tin metal. In order to improve the utilization rate of the target, the cavity structure also includes a transmission mechanism 9 that drives the target 8 to move left and right. The transmission mechanism 9 includes a rack 10 and a gear 11 meshing with the rack 10, such as Figure 4 As shown, the tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com