Composite demolding process for UHPC (Ultra High Performance Concrete) fair-faced veneer

A finishing and process technology, applied in the field of composite demoulding technology, can solve the problems of surface color shift, reduce the number of cycles, increase production cost, etc., reduce the speed of mold damage and deterioration, reduce cleanliness requirements, and ensure The effect of the release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

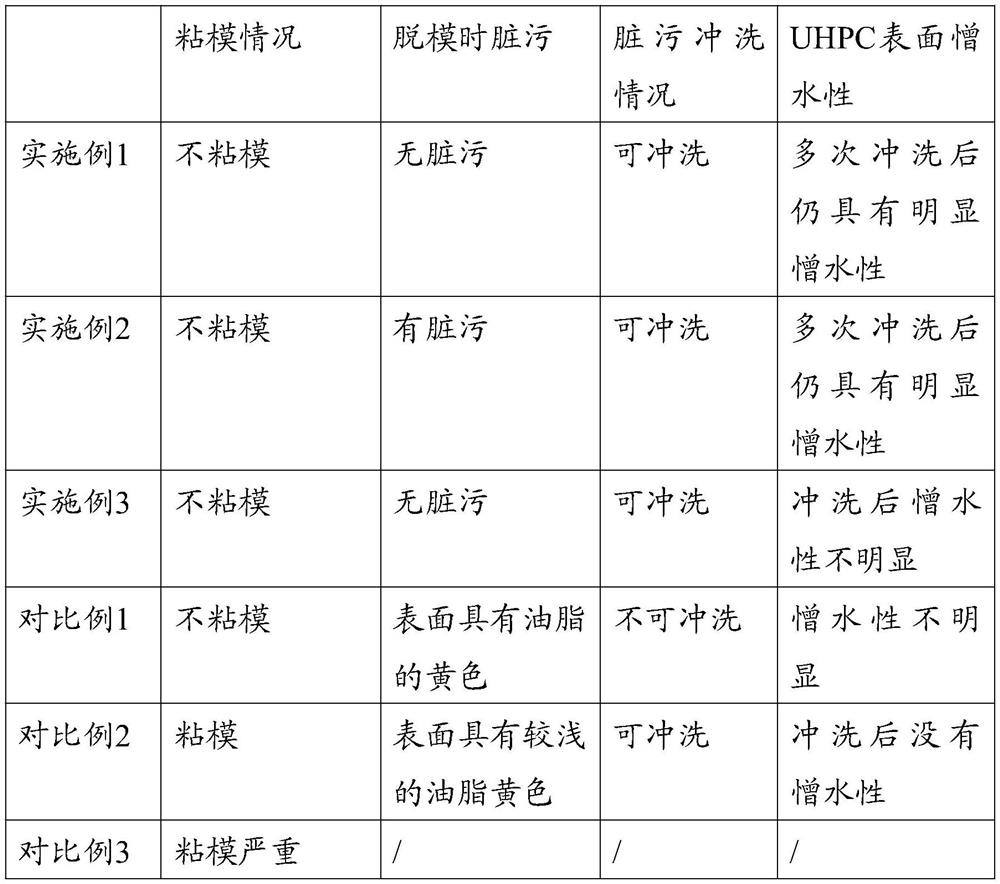

Examples

Embodiment 1

[0024] A composite demoulding process that can be used for UHPC clear water surface includes the following steps:

[0025] Step 1: Use liner seven 50 produced by Shanghai Kao Chemical Co., Ltd. (special mold release agent for fair-faced concrete, composed of paraffin oil, fatty acid, alkyl polyoxyethylene (7) ether, and alkyl polyoxyethylene (6) ether) As a release agent, dilute it with water at a ratio of 1:4 according to the instructions, and use a non-woven cloth dipped in the solution to brush it together so that no white solution remains on the surface of the mold.

[0026] Step 2: Prepare 1-2% sodium stearate solution with hot water at 60-80°C, and pour it into a metal watering can, which is placed in hot water at 80°C for use.

[0027] The third step: after the first step release agent forms a film in the mold (such as after the release agent emulsion film becomes transparent, or after the oily release agent film becomes flat under the action of surface tension), use th...

Embodiment 2

[0030] Step 1: Brush or spray conventional waste engine oil release agent to ensure that the surface of the release agent layer is smooth. If brush marks remain on the surface, replace the brushing tool, such as non-woven brushing.

[0031] Step 2: Prepare 1-2% potassium stearate solution with hot water at 60-80°C, and pour it into a metal watering can, which is placed in hot water at 80°C for standby.

[0032] The third step: after the first step release agent forms a film in the mold (such as after the release agent emulsion film becomes transparent, or after the oily release agent film becomes flat under the action of surface tension), use the prepared stearic acid Potassium hot solution is sprayed on the release agent film, and it needs to be sprayed in the form of mist. When the small droplets of potassium stearate solution are adsorbed on the surface of the release agent film, the temperature drops rapidly to form a solid paste, thereby preventing potassium stearate from ...

Embodiment 3

[0035] Step 1: Use liner seven 50 produced by Shanghai Kao Chemical Co., Ltd. (special mold release agent for fair-faced concrete, composed of paraffin oil, fatty acid, alkyl polyoxyethylene (7) ether, and alkyl polyoxyethylene (6) ether) As a release agent, dilute it with water at a ratio of 1:4 according to the instructions, and use a non-woven cloth dipped in the solution to brush it together so that no white solution remains on the surface of the mold.

[0036] Step 2: Prepare 1-2% calcium stearate solution with hot water at 60-80°C, and pour it into a metal watering can, which is placed in hot water at 80°C for standby.

[0037] The third step: after the first step release agent forms a film in the mold (such as after the release agent emulsion film becomes transparent, or after the oily release agent film becomes flat under the action of surface tension), use the prepared stearic acid The calcium hot solution is sprayed on the release agent film, and it needs to be spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com