Constant-temperature and low-temperature variable-frequency water flow heat exchange system

A technology of heat exchange system and water-side heat exchanger, which is applied to fluid heaters, fluid heater control, lighting and heating equipment, etc. The loss of electric power, the realization of output loss, and the effect of satisfying multi-energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

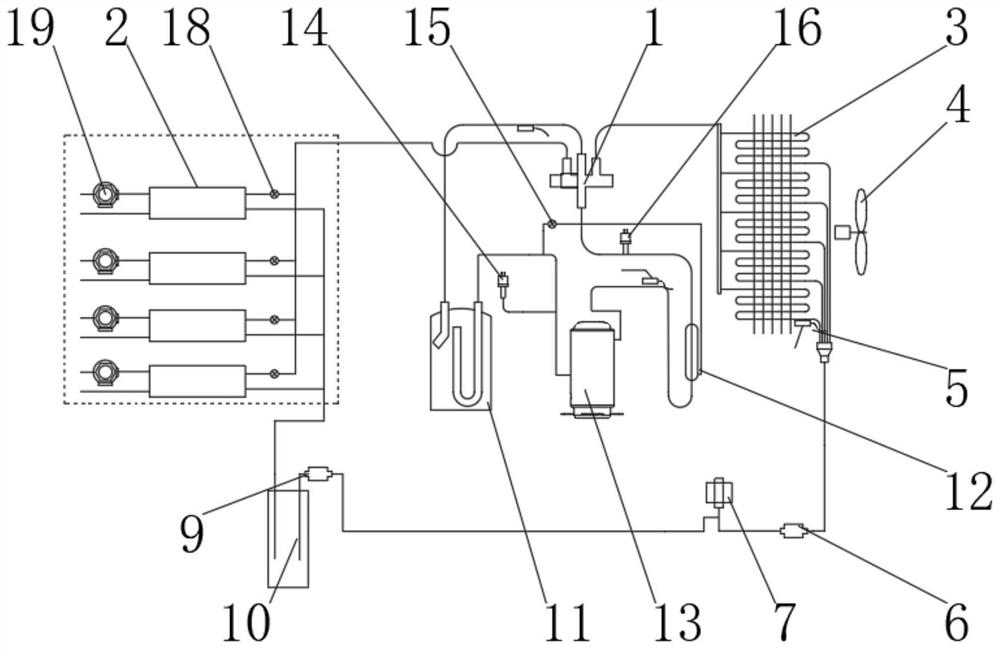

[0017] refer to figure 1 , normal temperature frequency conversion water flow heat exchange system, including four-way reversing valve 1 and fan 4, four-way reversing valve 1 is connected to water-side heat exchanger 2 through pipelines, and four-way reversing valve 1 is connected to water-side heat exchanger 2 through pipelines A heat exchanger 3, a T defrost sensor 5 is connected to the heat exchanger 3 through a pipeline, a first filter 6 is connected to the T defrost sensor 5 through a pipeline, and a main filter 6 is connected to the first filter 6 through a pipeline. electronic expansion valve 7, the main electronic expansion valve 7 is connected with a second filter 9 through a pipeline, the second filter 9 is connected with a liquid reservoir 10 through a pipeline, and the liquid reservoir 10 is connected with a pipeline through a pipeline The water side heat exchanger 2, the four-way reversing valve 1 is connected to the gas-liquid separator 11 through the pipeline, t...

Embodiment 2

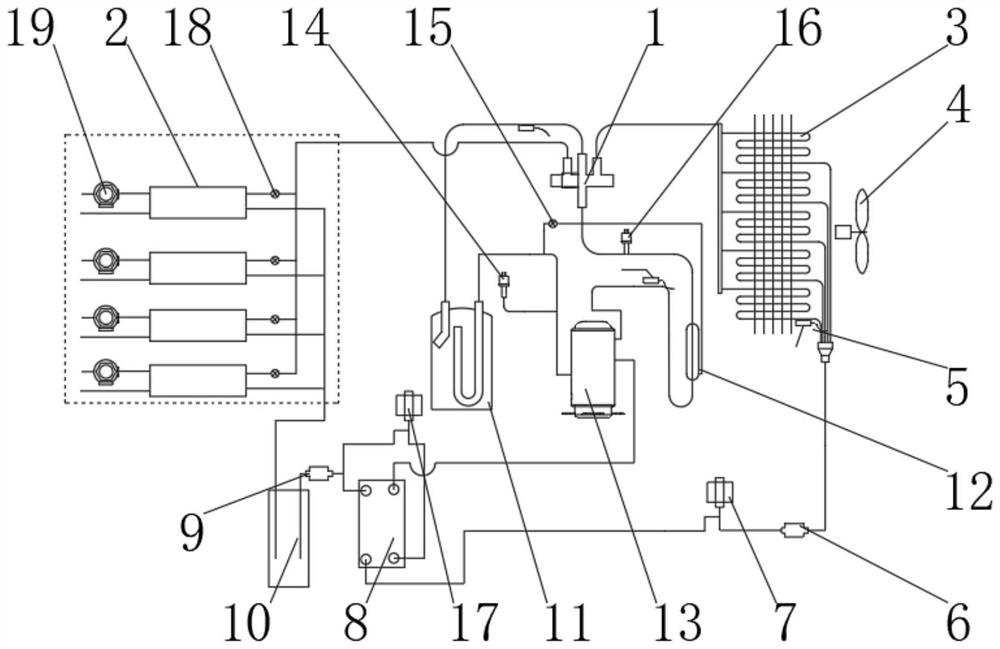

[0024] refer to figure 2 , the low-temperature frequency conversion water flow heat exchange system, on the basis of Embodiment 1, especially includes an economizer 8, the main circuit electronic expansion valve 7 is connected to an economizer 8 through a pipeline, and the economizer 8 is connected to an auxiliary circuit electronic valve through a pipeline. The expansion valve 17 is connected to the second filter 9 through pipelines on the economizer 8, and the auxiliary circuit electronic expansion valve 17 is connected to the second filter 9 through pipelines. By arranging the above structure, the conversion from the normal temperature frequency conversion multi-system hot water system to the low temperature frequency conversion multi-system hot water system can be realized.

[0025] When the low-temperature frequency conversion water flow heat exchange system is running, the low-voltage switch 14 and the high-voltage switch 16 are connected to the external power supply to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com