Photovoltaic backboard and preparation method and application thereof

A technology of photovoltaic backplane and quality parts, which is applied in the direction of photovoltaic power generation, semiconductor devices, electrical components, etc., and can solve problems such as the loss of protection of the backplane, high local temperature of components, and packaging failure.

Pending Publication Date: 2022-05-13

乐凯胶片股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The entire preparation process of the backplane is complicated, the operation cycle is long, and the organic solvent is volatilized during the production process, polluting the environment

In addition, in the process of long-term outdoor use, there is a problem that the interlayer adhesive force will decrease, which will easily cause separation and peeling between the layers, and the backplane will lose its protective effect.

[0003] In addition, due to the pressure of cost, the size of battery components on the market has begun to develop towards large size and high power, and the operating temperature of the components will also rise. If some battery cells have defects or foreign objects block problems, the power generation components will be converted into load components. , will lead to an abnormally high local temperature of the component, and then abnormal phenomena such as backplane bubbling and hot spots will appear. If the heat resistance of the backplane is not enough, the backplane in the area corresponding to the local high temperature point may be burned through, which will lead to package failure.

However, there are few researches on solving the hot spot problem of the backsheet in related technologies. Therefore, improving the heat resistance of the co-extruded backsheet is also an urgent problem to be solved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~4 and comparative example 1~4

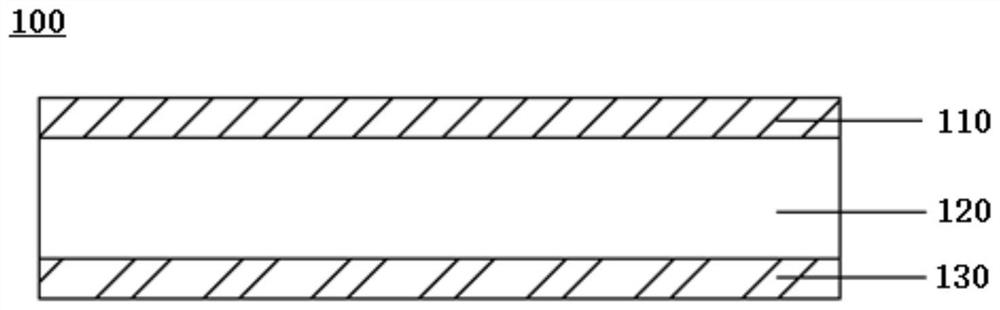

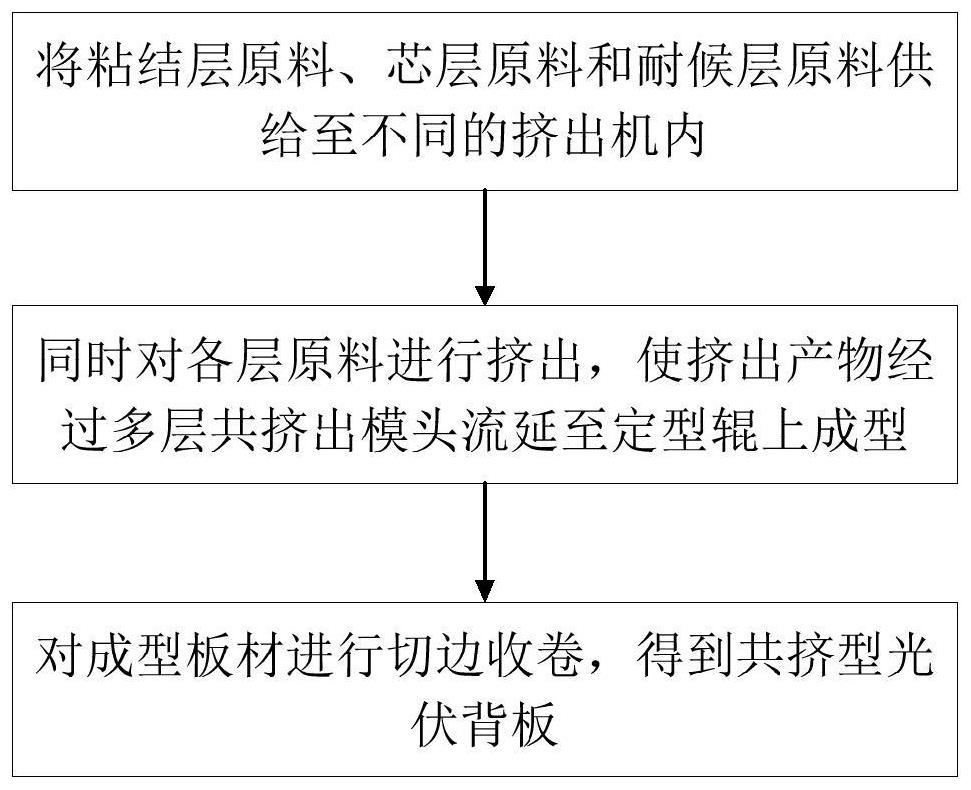

[0064] Among them, the structure of the photovoltaic backsheet in Examples 1-4 and Comparative Examples 1-4 is a three-layer structure of adhesive layer, core layer and weather-resistant layer, and the core layer and The weather-resistant layer formula is the same, see Table 1 for details; see Table 2 for the adhesive layer formulas of Examples 1-4 and Comparative Examples 1-4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Login to View More

Abstract

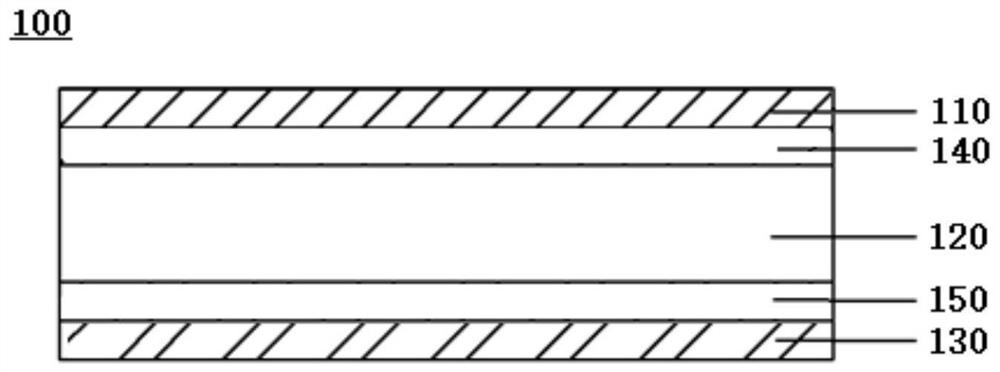

The invention discloses a photovoltaic backboard and a preparation method and application thereof. The photovoltaic backboard at least comprises a bonding layer, a core layer and a weather-resistant layer which are sequentially arranged from inside to outside, and the bonding layer comprises, by mass, 50-80 parts of heat-resistant polyamide, 5-20 parts of tackifying resin, 1-10 parts of ionic polymer, 1-30 parts of first filler and 0.1-5 parts of first anti-aging agent; the core layer comprises 50-80 parts by mass of first polypropylene, 5-20 parts by mass of a first modified material, 1-30 parts by mass of a second filler and 0.1-5 parts by mass of a second anti-aging agent; and the weather-resistant layer comprises 50-80 parts by mass of second polypropylene, 5-20 parts by mass of a second modified material, 1-30 parts by mass of a third filler, 0-25 parts by mass of polyamide and 0.1-5 parts by mass of a third anti-aging agent. The photovoltaic backboard has good heat resistance, weather resistance, cohesiveness and interlayer cohesive force, and the heat resistance of the photovoltaic backboard can be greatly improved.

Description

technical field [0001] The invention belongs to the field of photovoltaic technology, and in particular relates to a photovoltaic backplane and a preparation method and application thereof. Background technique [0002] As a clean, non-polluting, and most abundant renewable energy source, solar energy has attracted widespread attention. With the goal of "carbon peaking and carbon neutrality", the state will Europeanize the optimization of industrial structure and energy structure in terms of policy, and clean energy will also usher in a larger market space. Solar cells are exposed to long-term outdoor wind, rain, ultraviolet rays and other natural factors. The backsheet should use a backsheet with excellent weather resistance and durability to protect the solar cell and prolong its service life. At present, the mainstream solar battery backsheet in the market is still dominated by multi-layer composite structure, which is mainly divided into composite type and coating type,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01L31/049H01L31/048H01L31/052B29C48/49B29C48/21B29C48/07

CPCH01L31/049H01L31/0481H01L31/052B29C48/07B29C48/21B29C48/49Y02E10/50

Inventor 孟丹范云峰白玉清马亚男邸喜强张文静李华锋柳青

Owner 乐凯胶片股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com