Pre-lithiation method of silicon monoxide negative electrode material

A negative electrode material, silicon oxide technology, applied in the direction of battery electrodes, lithium batteries, structural parts, etc., can solve the problems of long reaction time, hindered lithium migration, difficult industrialization promotion, etc., to reduce production costs and improve pre-lithiation The effect of speed and ease of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for pre-lithiation of silicon oxide negative electrode material, comprising the following steps

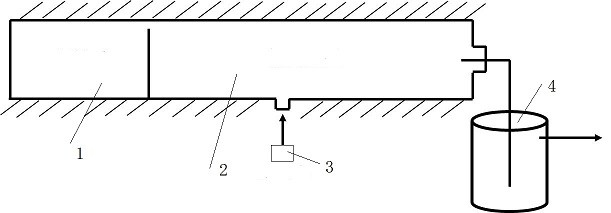

[0023] (1) Pre-lithiation: Crushing, pulverizing, and grinding the silicon dioxide and elemental silicon so that the diameter of the silicon dioxide and elemental silicon particles is 80 nanometers, and the nano-scale silicon dioxide and elemental silicon are mixed at a ratio of 90:10 The molar ratio is mixed evenly and pressed into a tube furnace, and the heating system of the tube furnace is turned on. The high temperature zone 1 is heated to 1200 °C at 8 °C / min, and the low temperature area 2 is heated to 400 °C at 4 °C / min. The inlet valve of lithium vapor 3 in the low temperature zone 2 of the tube furnace was maintained for 4 minutes, and then the vacuum system 4 of the tube furnace was opened to maintain the vacuum at -0.09MPa. The material SiO@Li particles were collected in the storage tank outside the tube furnace, and the lithium process as attached figu...

Embodiment 2

[0030] A method for pre-lithiation of silicon oxide negative electrode material, comprising the following steps

[0031] (1) Pre-lithiation: Crushing, pulverizing, and grinding the silicon dioxide and elemental silicon so that the diameter of the silicon dioxide and elemental silicon particles is 90 nanometers, and the nano-scale silicon dioxide and elemental silicon are mixed at an ratio of 80:20 The molar ratio is mixed evenly and pressed into a tube furnace, and the tube furnace heating system is turned on. The high temperature zone 1 is heated at 10°C / min to 1500°C, and the low temperature zone 2 is heated at 5°C / min to 600°C. In between, open the inlet valve of lithium vapor 3 in the low temperature zone of the tube furnace and maintain it for 5 minutes, then turn on the vacuum system 4 of the tube furnace to maintain the vacuum at -0.08MPa, and collect the material SiO@Li particles in the storage tank outside the tube furnace , the pre-lithiation process is as attached ...

Embodiment 3

[0038]A method for pre-lithiation of silicon oxide negative electrode material, comprising the following steps

[0039] (1) Pre-lithiation: Crushing, pulverizing, and grinding the silicon dioxide and elemental silicon so that the diameter of the silicon dioxide and elemental silicon particles is 100 nanometers. The molar ratio is mixed evenly and pressed into a tube furnace, and the heating system of the tube furnace is turned on. The high temperature zone 1 is heated at 12°C / min to 1800°C, and the low temperature zone 2 is heated at 6°C / min to 800°C. In between, open the inlet valve of lithium vapor 3 in the low temperature zone of the tube furnace and maintain it for 6 minutes, then turn on the vacuum system 4 of the tube furnace to maintain the vacuum at -0.07MPa, and collect the material SiO@Li particles in the storage tank outside the tube furnace , the pre-lithiation process is as attached figure 1 shown;

[0040] (2) Disproportionation / carbon coating: mix the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com